Research - (2019) Volume 7, Issue 6

Comparison between Stresses Induced on the Dental Implant Retaining Screw before and after Tightening

Mohamed Tharwat Hamed1,2* and Hisham Abdullah Mously1

*Correspondence: Mohamed Tharwat Hamed, Associate Professor, Department of Oral & Maxillofacial Prosthodontics, King Abdulaziz University Faculty of Dentistry, Saudi Arabia, Email:

Abstract

The untightening resistance has a negative impact on the stability of implant-abutment system. However, there is a need to retighten the screws periodically.

Aim: This study aims to compare the stress level on the dental implants before and after tightening of the screw. Methods: A 3D geometrical idealization was constructed in place of a missing mandible first molar of an adult. An integrated retaining screw was fixed to a standard Ti-6Al-4V abutment after osseointegration. Model’s geometry was exported to generate threedimensional mesh.

Results: The results were acquired with 14 values of the friction coefficient for type III gold and Ti-6Al-4V titanium alloy screws. There was variation in values of gold screw before tightening; however, it was considerably low as compared to the corresponding values in the case of titanium screw. Moreover, the magnitudes of Pa of gold screw were less as compared to the titanium screw. There is a decrease in stresses at maximum tightening moment because of increase in coefficient of friction for assembling different parts. Moreover, the magnitudes of Pa of gold screw were less as compared to the titanium screw.

Conclusion: The invariable decrease in the release of wrench tightening moment was due to the increase on the wrench tightening moment. Moreover, the decrease in the stresses at maximum tightening moment applied to screw was because of increase in coefficient of friction for assembling different parts.

Keywords

Dental implants, Friction, Prosthesis, Induced stresses, Retaining screw

Introduction

The partially or totally edentulous patients are nowadays rehabilitated using dental implants. High levels of success and advantages associated with dental implants have resulted in great acceptance of this approach, as compared to other types of rehabilitation. The development of implant components of the prosthetic connection by the implant manufacturers increased the success rates of dental implants by providing better mechanical stability to the whole implant assembly. The dental implant system comprised of cement retained implant and screw retained implant provide support to different kinds of restorations. However, the use of screwed prostheses is more advantageous as compared to cemented prostheses because they are easily replaceable without causing damage to the implant [1].

The parts of the implant are kept connected and steady during the tightening of prosthetic screw after applying torque. However, preload tension is created in the screw because of stabilizing the screw joint. The tightening of screw, also termed as preload mainly functions to hold the prostheses with the implant. The intensity of preload that is applied to the screw, friction coefficient, and shape of the screw threads play an important role in maintaining mechanical stability of the implant-prostheses system. The compressive force between the screw threads and prosthetic component increase because of tightening of the torque increases preload on the implants [2]. The absence of movement between the implant and abutment is determined by evaluating the balance between preload and the occlusal forces. The recovery of elastic distortion and elastic elongation of the screw is induced because of applying preload on the implants.

The screw is kept tightened during the masticatory functions, if the threads are kept under tension. However, it is possible that under certain circumstances, there is a loss of condition of the screw preload. The change in the roughness and friction coefficient between the implant fixture and screw threads, results in the deformation and flattening of the surface of the screw thread, due to axial loading [3]. The screw bending and plastic deformation of the screw threads develop because of vibrations due to occlusal forces. This may lead to loosening of the prosthetic screw due to loss of preload [4]. The displacement of dental prostheses can be prevented if coated abutment screw is used as the coating decreases the friction coefficient and increase the preload for specific tightening torque [5].

There is a negative impact of untightening resistance on the stability of implant-abutment system. It has been shown that Ti screws without coating are more stable as compared to Parylene, Teflon, TiCN, and TiN coated screws [1]. A study conducted by Elias, et al. [5] showed that a certain combination of screw size, material, and coating is specified based on magnitude of the untightening torque. The issue regarding the change or retightening of abutment and prosthesis screw needs to be discussed as this information is not provided by the manufacturers. It is necessary for the experts to be aware about frequent tightening and replacement of screws. A study recommended avoiding the retightening of screws [6]; whereas, another study conducted by Siamos, et al. [7] stated that there is a need to retighten the screws periodically. To erase this confusion, the present study aims to compare the stress level on the dental implants before and after tightening of the screw.

Material and Methods

A 3D geometrical idealization for standard Ti- 6Al-4V Straumann implant between 4.1 mm and 12 mm long was constructed and inserted vertically in place of a missing mandible first molar of an adult. This idealization was from the manufacturer in IGES format and was processed in the computer-aided design (CAD). CAD software was used to simplify the models, as they fill the socket in abutment screw head by taking away the groove on the upside of the abutment. Along the mesiodistal direction, the bone surrounded with tissue was extended till 14 mm; whereas, the width of bone sagittal occlusal was extended till 11 mm. All the geometries concerning cancellous and cortical bones were measured. These bones were measured with the help of large number of cube-like samples for the evaluation of anisotropic properties in three principal axes along the length of the whole femur.

A tightening moment was recommended after osseointegration of an integrated retaining screw that was fixed to a standard Ti-6Al-4V abutment. The dimensions of implant were measured by using a failed implant comprising of the abutment and the screw. The ANSYS Release 13.0 FEA software was used for exporting the model’s geometry to generate three-dimensional mesh. Mesh trials were obtained to achieve convergence with that final mesh based on total elastic strain energy. The relevant mechanical properties of materials used in this study have been listed in Table 1.

| Material | Elasticity modulus | Poisson’s ratio |

|---|---|---|

| Titanium alloy Ti-6Al-4V | 117 | 0.33 |

| Type III Gold | 100 | 0.33 |

| Cortical Bone | 14.7 | 0.3 |

| Cancellous Bone | 0.49 | 0.3 |

| Soft Tissue | 1.18 × 10-3 | 0.45 |

Table 1: Mechanical properties of different materials.

The cortical bone fixed from the bottom and the displacements of both mesial and distal planes of the model were constrained. At the surface of the contact, no separation was allowed for different parts of the assembly. The study has assumed the contact of screw surface with the implant and the abutment. Moreover, the analysis was invoked to load the screw head for the simulation of its tightening. The study has analyzed two screw materials of Ti-6Al-4V titanium alloy and type III gold. Fourteen values ranging from 0 to 2 have been used in the study. The value of M was 30 N.cm for the titanium screw and 20 N.cm for the gold screw. For each value, the linear elastic stress-deformation analysis was implemented. Similarly, a total of fourteen analyses were carried for each screw material. Moreover, the problem was solved through ANSYS that helped in computing von Mises equivalent stress present in component of the assembly to compare with the yield stress of its material.

Results

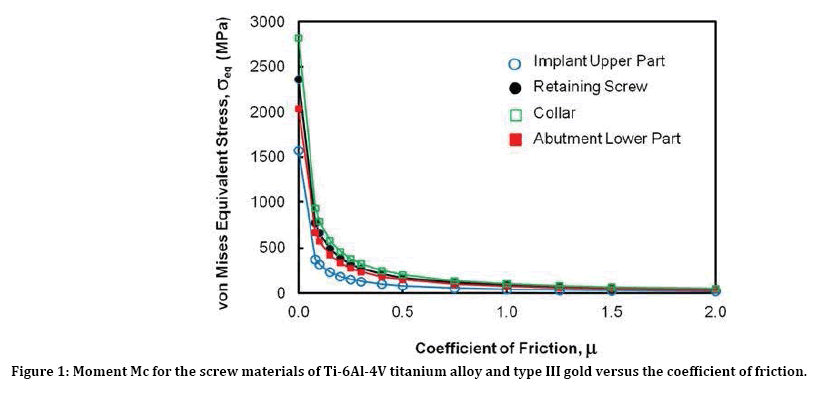

Stress and screw retaining before tightening The fatigue damage parameter was below the Ti- 6AI-4V threshold value for chewing force <809N, as it experienced the most stressed site within the retaining screw, against the magnitude of the chewing force. The graph between the bottom surface of the screw head and its contact surface with the abutment for the Ti-6Al-4V titanium alloy and type III gold screws has been presented in Figure 1. The friction acting on its threaded surface was overcome based on a difference between the wrench turning momentums applied on the top surface of screw head. The results showed that there was a variation in the values of gold screw; however, it was considerably low as compared to the corresponding values in the case of titanium screw.

Figure 1: Moment Mc for the screw materials of Ti-6Al-4V titanium alloy and type III gold versus the coefficient of friction.

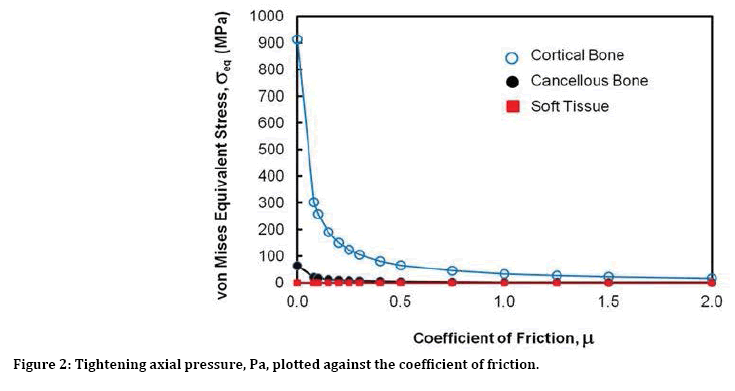

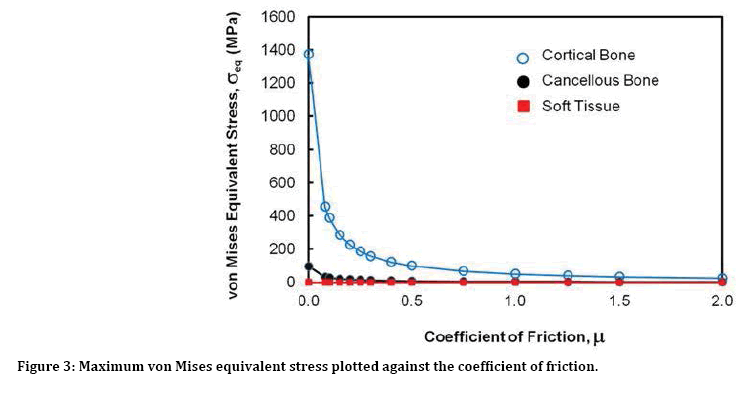

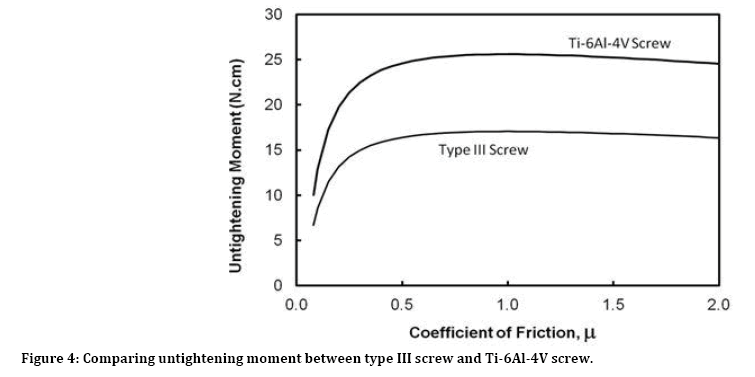

The tightening axial pressure plotted against titanium and gold screws has been presented in Figure 2, which showed that magnitudes of Pa in the case of the gold screw were less, as compared to those used for titanium screw. Figure 3 shows the variation of the maximum von Mises equivalent stress due to the presence of metallic parts retaining screw in the cases of titanium. The stress values generated within the parts were arranged in a descending order as the upper plant of the implant is followed by the retaining screw, the screw collar, and the abutment lower part. Similarly, Figure 4 shows difference in arrangement at low values with greater stress on the screw collar and the decreased stress on the implant upper part.

Figure 2: Tightening axial pressure, Pa, plotted against the coefficient of friction.

Figure 3: Maximum von Mises equivalent stress plotted against the coefficient of friction.

Figure 4: Comparing untightening moment between type III screw and Ti-6Al-4V screw.

Stress and screw retaining after tightening

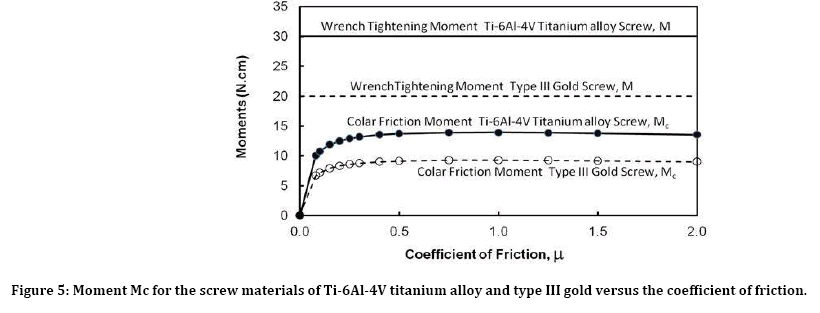

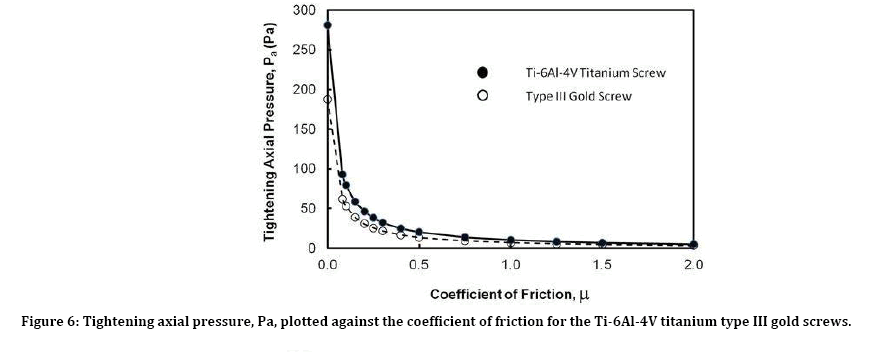

The effect of μ on the frictional moment Mc between the bottom surface of the screw head and contact surface with the abutment for the Ti-6Al-4V titanium alloy and type III gold screws has been presented in Figure 5. A constant value at μ>0.5 is achieved for both screw materials as Mc increases with increasing μ. As compared to the values in the case of titanium screw, the values of both Mc and Ms for all μ values are invariably less. The plotting of tightening axial pressure, Pa, against μ for the titanium and gold screws has been illustrated in Figure 6. It shows that the magnitudes of Pa in the case of the gold screw are less than those corresponding to the titanium screw.

Figure 5: Moment Mc for the screw materials of Ti-6Al-4V titanium alloy and type III gold versus the coefficient of friction.

Figure 6: Tightening axial pressure, Pa, plotted against the coefficient of friction for the Ti-6Al-4V titanium type III gold screws.

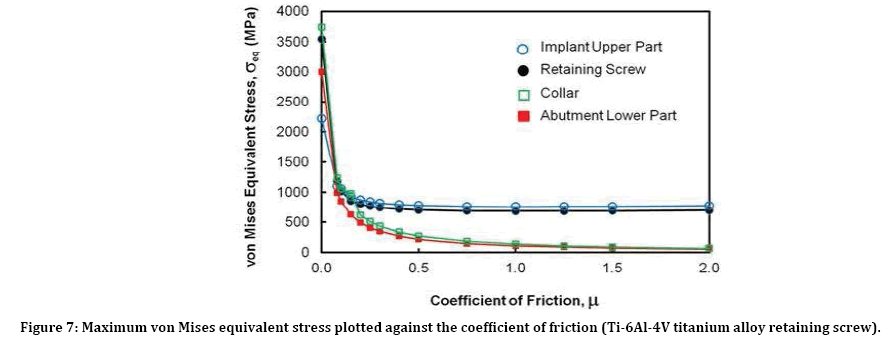

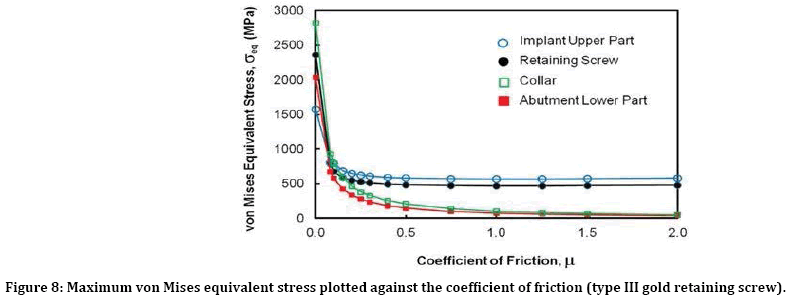

Figure 7 depicts the variation of the maximum von Mises equivalent stress σeq with μ because of the presence of metallic parts in the case of the titanium retaining screw. The stress values generated within the parts were arranged in a descending order as the implant upper part followed by the retaining screw, the screw collar and finally the abutment lower part because of higher values. However, Figure 8 depicts that the stresses in the case of type III gold screw were less than those computed in the case of the titanium screw.

Figure 7: Maximum von Mises equivalent stress plotted against the coefficient of friction (Ti-6Al-4V titanium alloy retaining screw).

Figure 8: Maximum von Mises equivalent stress plotted against the coefficient of friction (type III gold retaining screw).

Discussion

The present study has compared stress level on the dental implants before and after tightening of the screw. The results were acquired with 14 values of the friction coefficient for type III gold and Ti-6Al-4V titanium alloy screws. The results showed variation in values of gold screw before tightening; whereas, after tightening the magnitudes of Pa of gold screws were less as compared to the titanium screw. Following the process of prosthesis, the retaining screw tended to lose the fracture before the implant fixture is damaged. This is likely to occur because of its metallurgic composition and reduced size. Proper understanding about the biomechanical parameters of the screw and its joints are required for the treatment of loosened screws. The screwed joint is tightened to maximize the fatigued life of the retaining screws. This is likely to provide protection against loosening of the screws. The frictional forces are maximized through optimal preload generated between the mating thread resulting in a stabilized implant complex [8]. The tension that developed in the screw is proportional to the applied torque in the preload. Excessive torque may result in plastic deformation; whereas, a good coupling is not guaranteed when the torque is lowered. This results in compromising mechanical stability of the implant-prosthesis system [1].

The release of wrench tightening moment decreased due to the increase on the wrench tightening moment. The present study also showed decrease in the stresses at maximum tightening moment applied to screw as the coefficient of friction for assembling different parts increased. The number of failures due to late implant fracture is also expected to increase because of the increase in popularity of dental implants. A previous study analyzed different causes of failure of dental implants due to implant fixture/abutment screw fractures along with enumeration of management and the preventive options for these failures [9]. The results seemed to be helpful in preparing plan by the clinicians for the implant-supported prosthesis treatment. The elimination of necessary occlusal and offaxial forces on implant-supported restorations is supported by the loosening of posterior abutment screws at higher percentage, as compared to anterior implants [10]. Previous studies have shown that the implant screws should be retightened 10 min after the initial torque application for reducing the settling effect [2,7,9].

Conclusion

There was variation in values of gold screw before tightening; however, it was considerably low as compared to the corresponding values in the case of titanium screw. Moreover, the magnitudes of Pa of gold screw were less as compared to the titanium screw. The invariable decrease in the release of wrench tightening moment was due to the increase on the wrench tightening moment. Moreover, the decrease in the stresses at maximum tightening moment applied to screw was because of increase in coefficient of friction for assembling different parts.

Acknowledgements

The author is very thankful to all the associated personnel in any reference that contributed in/ for the purpose of this research. Further, this research holds no conflict of interest and is not funded through any source.

References

- Al Jabbari YS, Fournelle R, Ziebert G, et al. Mechanical behavior and failure analysis of prosthetic retaining screws after long‐term use in vivo. Part 4: Failure analysis of 10 fractured retaining screws retrieved from three patients. J Prosthodont 2008; 17:201-210.

- Bakaeen LG, Winkler S, Neff PA. The effect of implant diameter, restoration design, and occlusal table variations on screw loosening of posterior single-tooth implant restorations. J Oral Implantol 2001; 27:63-72.

- Cho SC, Small PN, Elian N, et al. Screw loosening for standard and wide diameter implants in partially edentulous cases: 3-to 7-year longitudinal data. Implant Dent 2004; 13:245-250.

- Doolab R. Dental implant retaining screws: The effect of using gold or titanium on preload. Doctoral Dissertation 2010.

- Elias CN, Figueira DC, Rios PR. Influence of the coating material on the loosing of dental implant abutment screw joints. Materials Sci Engin 2006; 26:1361-1366.

- Gupta S, Gupta H, Tandan A. Technical complications of implant-causes and management: A comprehensive review, National J Maxillofac Surg 2015; 6:3-8.

- Siamos G, Winkler S, Boberick KG. The relationship between implant preload and screw loosening on implant-supported prostheses. J Oral Implant 2002; 28:67-73.

- Park CI, Choe HC, Chung CH. Effect of surface coating on the screw loosening of dental abutment screws. Metals Materials Int 2004; 10:549.

- Saboury A, Neshandar Asli H, Vaziri S. The effect of repeated torque in small diameter implants with machined and premachined abutments, Clin Implant Dent Related Res 2012; 14:224-230.

- Secatto FB, Elias CN, Segundo AS, et al. The morphology of collected dental implant prosthesis screws surface after six months to twenty years in chewing, Dent Oral Craniofac Res 2017; 3.

Author Info

Mohamed Tharwat Hamed1,2* and Hisham Abdullah Mously1

1Associate Professor, Department of Oral & Maxillofacial Prosthodontics, King Abdulaziz University Faculty of Dentistry, Jeddah, Saudi Arabia2Associate Professor, Department of Fixed Prosthodontics, Cairo University School of Dentistry, Cairo, Egypt

Citation: Mohamed Tharwat Hamed, Hisham Abdullah Mously, Comparison between Stresses Induced on the Dental Implant Retaining Screw Before and After Tightening, J Res Med Dent Sci, 2019, 7(6): 94-100.

Received: 27-Nov-2019 Accepted: 12-Dec-2019