Research Article - (2022) Volume 10, Issue 8

Cyclic Fatigue Resistance of Three Different Rotary Endodontic Instruments with Design Modification

Ali S Abu Naila* and Hussain F Al-Huwaizi

*Correspondence: Ali S Abu Naila, Department of Conservative and Esthetic Dentistry, University of Dentistry-Baghdad, Iraq, Email:

Abstract

Background: CF (Cyclic Fatigue) resistance of Dentsply Pro Taper Universal (PTU), Pro Taper Gold (PTG), and Pro Taper

Next (PTN) nickel titanium (NiTi) rotary files was evaluated in comparision with simulated files with same design and our

study design.

Methods: For PTU and PTG study design modification is to leave the apical 8 mm of S1 and the apical 3 mm of S2 as unmilled,

F1 only the apical 5 mm would have cutting blades. For PTN is to leave the apical 8 mm of X1 and, while for X2 is to

leave the coronal 8 mm as un-milled. Ten instruments for each file (S1, S2, F1, X1 and X2); total 240 files (80 pieces for

Dentsply, 80 pcs for simulated and 80 pieces for study design), files rotated in simulated canal until fracture.

Conclusion: PTG instruments were most resistant to CF, followed by PTN and PTU. S1 and S2 files making the non-active

part plane will increase CF resistance while for F1 files will decrease CF resistance. For PTN files groups, for X1 files making

the non-active part plane will increase CF resistance while for X2 files will decrease CF resistance.

Introduction

Due to the errors in techniques caused by stainless steel files, the innovation of Nickel-Titanium (NiTi) for production of rotary endodontic files [1]. The necessary characteristics of NiTi rotary files are shape memory, great flexibility, and preserving the original shape of the canal during preparation of the canal. Peculiarly, elasticity of NiTi files is double or triple higher times than stainless-steel files because the modulus of elasticity of nickel titanium is low [2,3]. The substance characteristics of NiTi and stainless-steel rotary instruments are presented in Table 1 Despite the great elasticity of NiTi rotary files, fracture also happened [4,5]. The cause of rotary NiTi files failure is either by flexural fracture (cyclic fatigue) or torsional fracture [6]. Research workers revealed that flexural fracture occurs during the flexion of the endodontic file at the highest area of curvature in the canal at time of rotation when the file is compressed and tensioned multiple times [5,7]. At the curvature outer wall, the file is tensioned while at the curvature inner wall, the file is compressed. Flexural fracture of the file happened during the rotation in multiple cycles at the curvature part of the canal. While torsional fracture occurred when whole part of the file keeps rotating while tip of the file locked inside the canal. So, the tip will be fractured when the elastic limit of the metal was less than the torque adjusted in the hand piece [7].

Table 1: Properties of NiTi and stainless steel rotary files.

| Properties | Ni-Ti alloy | Stainless steel |

|---|---|---|

| Ultimate tensile strength | ~1240 MPa | ~760 MPa |

| Density | 6.45 gm/cm3 | 8.03 gm/cm3 |

| Recoverable elongation | 0.08 | 0.008 |

| Effective modulus | ~48 GPa | ~193 GPa |

| Coefficient of thermal expansion | 6.6x10-6-11x10-6 C-1 | 17.3x10-6 C-1 |

| Micro-hardness | 303-362 VHN | 522–542 VHN |

Mechanical characteristics and elasticity was enhanced when the nickel titanium alloys was heat treated [8]. Austenite, R phase, and marten site are the phases of nickel titanium alloys. In the marten site phase the nickel titanium files are soft, malleable and easily can be distorted, but shape can be regain when it will be warmed to a degree more than the transformation temperature. The finish degree of temperature for traditional super-elastic is about (16-31°C), when compared with controlled memory wire and M-wire alloys which reveal greater finish temperatures at austenite transformation (55 and 50°C), respectively [6,9]. At human body temperature, the traditional super-elastic NiTi instrument are mainly austenite structure while the heat treated NiTi files are mostly at the marten site phase. Pro Taper Universal (PTU) and Pro Taper Gold (PTG) rotary files have same design; but, PTG files have dissimilar metallurgy supported by heat-treatment techniques to improve elasticity, flexural fracture resistance, and higher durability [10]. Pro Taper Next (PTN) files made by M-wire technology, in which the plain nickel titanium wires are thermos mechanically treated. The fracture resistance for PTN files has been improved by the unique unsymmetrical rotary action and decreasing the touching between the file and the root canal walls [4].

Cyclic fatigue of rotary endodontic files tested by the application of bending during rotational movement, many devices and methods was applied for the NiTi rotary endodontic to evaluate the flexural fatigue resistance. The principal measuring methods which used to measure the shape of the canal are the curvature (radius and angle). Some investigators showed that the collected data could be not trustworthy or logical if the guidelines of the machine didn’t respect the shape and design of the instrument [5,7]. In order to avoid these mishaps, simulated canals (0.1-0.3) mm more than the measurements of the file need to be tested [11,12]. For pro taper universal and pro taper gold, the design of S1 file to enlarge the coronal area of the canal, S2 file to enlarge the middle area of the canal. In spite of, S1 and S2 shaping files were designed to prepare the upper two thirds of the root, but they make also preparation for the coronal area of the apical part. F1, F2 and F3 finishing files are responsible for more preparation for the middle part and complete preparation for the apical part [13]. So we think that we need to make the file design Plain (free of flutes) in the part which supposed not to be responsible in the canal preparation.

Materials and Methods

Study design

The Shaping files (S1 and S2) have small-sized tips that act as guides to passively follow the path of the canal previously secured with hand files. Increasingly larger percentage tapers over the active length of each file ensures shaping the coronal and middle thirds. The Finishing files (F1) have fixed tapers from D1 to D3, and then decreasing percentage tapers from D4 to D16. This design feature limits the Finishing files to working in their apical extents and reduces the possibility of over preparing the coronal two-thirds of a canal.

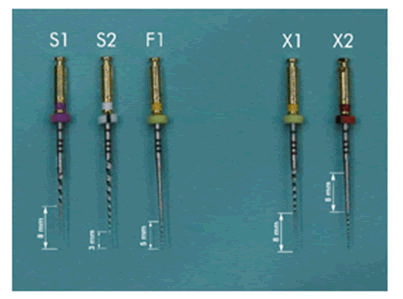

The recommended design modification is to leave the apical 8 mm of file S1 as blank shaft with round cross section (un-milled), and the apical 3 mm of file S2 un-milled, whereas for files F1 only the apical 5 mm would have cutting blades leaving the middle and coronal portions un-milled (bladeless). For the pro taper next files is to leave the apical 8 mm of file X1 file blank shaft with round cross section (un-milled) while for X2 files is to leave the coronal 8 mm as blank shaft with round cross section (un-milled) (Figure 1) [17].

Figure 1: shaping files of the study design.

Preparation of artificial canals

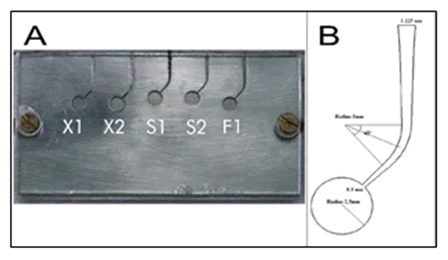

Artificial canals have been machined in plates made from stainless-steel and the dimensions were (100 mm, 50 mm, 10 mm) by utilizing the laser micromachining technology. For machining LASERTEC 40 (Deckel Maho Gildemeister, Ger.) was used, and it comprises of Q-switched Neodynium-doped Yttrium Aluminum Garnt (Nd: Y3 Al5 O12) (Nd: YAG) laser. The artificial canal that is to be machined has been modeled with the use of the CATIA V-5® program and laser path programming has been done with a Standard Triangle Metals language file of proprietary machine program, which operated at a 1064 nm wavelength with a peak power equal to 30. Laser was concentrated on the metal piece by using the galvano scanner after the establishment of parameters for laser processes, and then layer by layer the canal was then machined [14]. In stainless-steel blocks, the artificial canals were machined with similar dimensions to the specifications of the file examined to avoid the file's binding in the testing apparatus 0.1 mm wide and +0.2 mm deep, allowing for some lateral movement within the canal For dimensions determination, a straight line was drawn along the long axis of canal’s coronal section at a 45-degree angle. A 2nd line is drawn along apical section of canal's long axis. Each of these lines has a point where the canal deviation starts (point a) or ends (pointb) the canal curvature. A circle with tangents at locations a and b represents the canal's curving segment. The number of the degrees on arc of circle between a and b points (Figures 2-4) (with a radius of 5 mm and a curvature centre 5 mm from the instrument tip) is the angle of curvature (Figure 2) [5,7]. As indicated in Table 2, the PTU and PTG equipment dimensions have been reported based on the instructions of the manufacturer. The manufacturer's exact dimensions for the PTN, as well as maximal PTN instruments’ diameters, as it has been measured with Digimizer® program have been listed in Table 3.

Figure 2: Custom-made stainless-steel blocks with dimensions corresponding to the dimensions of Pro Taper Next (X1, X2), Pro Taper Gold (PTG), and pro taper universal (PTU) (S1, S2, F1): +0.1 mm in width and +0.2 mm in depth, with an angle of curvature of 45°, a radius of curvature of 5 mm, and a centre of curvature 5 mm from the tip of the instrument (A); (B) Two-dimensional draft of artificial canal.

Table 2: Dimensions of PTU and PTG from the manufacturer.

| Active part length (mm) | Diameter (mm) | ||

|---|---|---|---|

| S1 | S2 | F1 | |

| 0 | 0.17 | 0.2 | 0.2 |

| 1 | 0.19 | 0.24 | 0.27 |

| 2 | 0.22 | 0.34 | 0.34 |

| 3 | 0.26 | 0.335 | 0.41 |

| 4 | 0.305 | 0.39 | 0.465 |

| 5 | 0.355 | 0.45 | 0.52 |

| 6 | 0.415 | 0.51 | 0.575 |

| 7 | 0.485 | 0.57 | 0.63 |

| 8 | 0.565 | 0.63 | 0.685 |

| 9 | 0.655 | 0.69 | 0.74 |

| 10 | 0.755 | 0.76 | 0.795 |

| 11 | 0.855 | 0.85 | 0.85 |

| 12 | 0.96 | 0.955 | 0.905 |

| 13 | 1.075 | 1.07 | 0.96 |

| 14 | 1.185 | 1.185 | 1.015 |

| 15 | 1.07 | ||

| 16 | 1.125 | ||

Table 3: Dimensions of the PTN from the manufacturer.

| Active part length (mm) | Diameter (mm) | |||

|---|---|---|---|---|

| X1 | X2 | |||

| Actual | Maximum | Actual | Maximum | |

| 16 | 1.16 | 1.26 | 1.2 | 1.3 |

| 13 | 0.98 | 1.06 | 1.11 | 1.15 |

| 9 | 0.7 | 0.76 | 0.84 | 1.06 |

| 6 | 0.49 | 0.534 | 0.63 | 0.7 |

| 3 | 0.31 | 0.35 | 0.43 | 0.45 |

| 1 | 0.21 | 0.23 | 0.31 | 0.34 |

| 0 | 0.17 | 0.17 | 0.25 | 0.25 |

Cyclic fatigue testing

Group number 1: Ten instruments of each pro taper universal S1, S2, F1 (Dentsply Mail filler), ten instruments of each S1, S2, F1 for simulated pro taper universal and ten files for each S1, S2, F1 for pro taper universal study design totally 90 pieces.

Group number 2: Ten instruments of each pro taper gold files S1, S2, F1 (Dentsply Mail filler), ten instruments of each S1, S2, F1 for simulated pro taper universal and ten files for each S1, S2, F1 for pro taper universal study design totally 90 pieces.

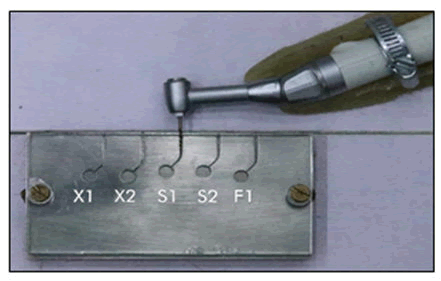

Group number 3: Ten instruments of each pro taper next X1, X2 (Dentsply Mail filler), ten files of X1 and X2 for simulated pro taper next files, and ten files of X1 and X2 for simulated pro taper next study design files totally 60 pieces. A main frame with stainless-steel blocks was affixed to which a moveable support for the hand piece was linked. As illustrated in Figure 2, the dental hand-piece has been installed on movable device which allowed for easy deployment of every tool inside artificial canal. The artificial canals were coated with glass for the purpose of preventing instruments from slipping out and for allowing the observation of instruments. In an artificial canal, the instruments were revolved until they fractured. The time till the instrument fractured was recorded using a timer. The speed of rotation as recommended by the manufacturer (300 rpm) until fracture.

Figure 3: CF testing device illustrating positioning of dental hand piece, NiTi rotary instrument, and stainless steel block.

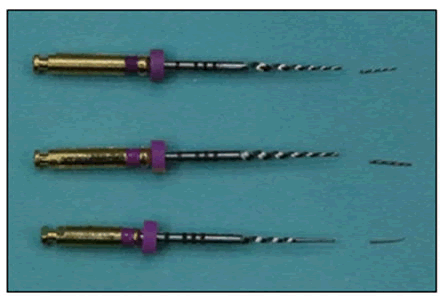

The instrument was observed and viewed through the glass throughout each test until it fractured, and time to the fracture has been recorded in seconds. Rotary files prior to and post fracture are shown in Figure 3. When the instrument fractured, the electric motor button was pressed again to stop the action. The shattered file was replaced with a new one once the slide was opened (Figure 4).

Figure 4: Fractured files.

Statistical analysis of the empirical data is essential for the proper interpretation and prediction of results. In this work, one-way ANOVA and Tukey’s tests were performed to analyse and compare the means. Statistical significance was set at P<0.05 [15,16].

Results

Pro taper universal

Descriptive statistics of cyclic fatigue fracture of pro taper universal files (Dentsply, Simulated and study) are presented in Tables 3-8. The results showed that for S1 and S2 files the Dentsply mean values were higher than Simulated and study groups, while for F1 files the simulated mean values were higher than Dentsply and study. Statistical comparisons among the groups were performed using one way ANOVA test among all S1 and F1 files groups revealed a statistically high significant difference (P<0.001) and non-significant difference among S2 files groups.

Table 4: Descriptive statistics of Cyclic fatigue fracture values of pro taper universal groups in Seconds.

| Pro taper universal | Descriptive statistics | Comparison | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | 95% confidence interval | Minimum | Maximum | F-test | P-Value | |||

| LB | UB | ||||||||

| S1 | Dentsply | 162.4 | 9.924 | 155.3 | 169.499 | 146 | 174 | 68.283 | 0 |

| Simulated | 118 | 8.419 | 111.977 | 124.023 | 104 | 129 | |||

| Study | 132.5 | 7.472 | 127.154 | 137.845 | 124 | 146 | |||

| S2 | Dentsply | 103.1 | 6.951 | 98.127 | 108.072 | 91 | 115 | 2.142 | 0.137 |

| Simulated | 98.9 | 8.748 | 92.641 | 105.158 | 88 | 114 | |||

| Study | 100.9 | 10.246 | 93.57 | 108.229 | 85 | 115 | |||

| F1 | Dentsply | 79.1 | 6.063 | 74.762 | 83.437 | 69 | 89 | 80.285 | 0 |

| Simulated | 110.7 | 7.318 | 105.464 | 115.935 | 99 | 121 | |||

| Study | 73.9 | 7.607 | 68.457 | 79.342 | 64 | 89 | |||

Further comparisons were performed using Tukey's HSD test and the results for S1 files groups revealed high significant difference (P<0.001) between Dentsply and Simulated groups, and between Dentsply and study group, while it was significant difference (P<0.05) in values between study and Simulated groups. For F1 files groups revealed a high significant difference (P<0.001) in values between Dentsply and Simulated group, and between study and Simulated group, while no significant difference (P>0.05) in values between Dentsply and study group, which shown in Tables 2 and 3.

Table 5: Tukey HSD among groups of each type of pro taper universal files.

| Pro taper universal | Mean difference | P-Value | 95% confidence interval | |||

|---|---|---|---|---|---|---|

| LB | UB | |||||

| S1 | Dentsply | Simulated | 44.4 | 0.000 (H.S) | 34.792 | 54.007 |

| Study | 29.9 | 0.000 (H.S) | 20.292 | 39.507 | ||

| Simulated | Study | -14.5 | 0.002 (S) | -24.1 | -4.892 | |

| F1 | Dentsply | Simulated | -31.6 | 0.000 (H.S) | -39.393 | -23.8 |

| Study | 5.2 | 0.241 (N.S) | -2.593 | 12.993 | ||

| Simulated | Study | 36.8 | 0.000 (H.S) | 29.006 | 44.593 | |

Pro taper gold

Descriptive statistics of cyclic fatigue fracture of pro taper gold files (Dentsply, Simulated and study) are presented in Table 6. The results showed that for S1 files the study mean values were higher than Simulated and dentsply groups, while for S2 and F1 files groups the Dentsply mean values were higher than simulated and study, Statistical comparisons among the groups were performed using one way ANOVA test and the results showed statistically high significant difference (P<0.001) in all files groups [24].

Table 6: Descriptive statistics of cyclic fatigue fracture values of pro taper gold groups in seconds.

| Protaper gold | Descriptive statistics | Comparison | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | S.D. | 95% Confidence Interval | Minimum | Maximum | F-test | P-Value | |||

| LB | UB | ||||||||

| S1 | Dentsply | 208.4 | 17.385 | 195.962 | 220.837 | 187 | 233 | 31.792 | 0 |

| Simulated | 219.8 | 14.512 | 209.418 | 230.181 | 202 | 241 | |||

| Study | 263.4 | 16.8 | 251.381 | 275.418 | 244 | 286 | |||

| S2 | Dentsply | 202.7 | 14.575 | 192.273 | 213.126 | 178 | 229 | 38.555 | 0 |

| Simulated | 157.9 | 10.332 | 150.508 | 165.291 | 140 | 171 | |||

| Study | 163.7 | 11.944 | 155.155 | 172.244 | 142 | 178 | |||

| F1 | Dentsply | 198.5 | 16.574 | 186.643 | 210.356 | 181 | 225 | 15.617 | 0 |

| Simulated | 163.9 | 12.022 | 155.299 | 172.5 | 148 | 182 | |||

| Study | 178 | 12.736 | 168.888 | 187.111 | 157 | 194 | |||

Further comparisons were performed using Tukey's HSD test and the results for S1 files groups revealed a non-significant difference (P>0.05) in values between Dentsply and Simulated group, while was high significant difference (P<0.001) in values between Dentsply and study group, and between study and Simulated groups. For S2 files groups results revealed a high significant difference (P<0.001) in values between Dentsply and Simulated groups and between Dentsply and study groups, and a non-significant difference (P>0.05) in values between study and Simulated groups. For F1 files revealed a high significant difference (P<0.001) in values between Dentsply and Simulated groups, significant difference (P<0.05) in values between Dentsply and study groups, and a non-significant difference (P>0.05) in values between study and Simulated group which shown in Table 7 [25].

Table 7: Tukey HSD among groups of pro taper gold files.

| Pro taper gold | Mean difference | P-Value | 95% confidence interval | |||

|---|---|---|---|---|---|---|

| LB | UB | |||||

| S1 | Dentsply | Simulated | -11.4 | 0.277 (N.S) | -29.452 | 6.652 |

| Study | -55 | 0.000 (H.S) | -73.052 | -36.947 | ||

| Simulated | Study | -43.6 | 0.000 (H.S) | -61.652 | -25.547 | |

| S2 | Dentsply | Simulated | 44.8 | 0.000 (H.S) | 31.041 | 58.558 |

| Study | 39 | 0.000 (H.S) | 25.241 | 52.758 | ||

| Simulated | Study | -5.80- | 0.555 (N.S) | -19.558 | 7.958 | |

| F1 | Dentsply | Simulated | 34.6 | 0.000 (H.S) | 19.162 | 50.037 |

| Study | 20.5 | 0.008 (S) | 5.062 | 35.937 | ||

| Simulated | Study | -14.1 | 0.078 (N.S) | -29.537 | 1.337 | |

Pro taper next

Descriptive statistics of cyclic fatigue fracture of pro taper next files (Dentsply, Simulated and study) are presented in Table 8. The results showed that for both X1 and X2 files the Dentsply mean values were higher than Simulated and study groups, Statistical comparisons among the groups were performed using one way ANOVA test among all X1 and X2 files groups revealed a statistically high significant difference (P<0.001).

Table 8: Descriptive statistics of Cyclic fatigue fracture values of pro taper next groups in Seconds.

| Protaper next | Descriptive statistics | Comparison | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | S.D. | 95% Confidence interval | Min. | Max. | F-test | P-Value | |||

| LB | UB | ||||||||

| X1 | Dentsply | 193.1 | 12.242 | 184.342 | 201.857 | 179 | 212 | 76.365 | 0 |

| Simulated | 128.2 | 11.321 | 120.101 | 136.299 | 114 | 145 | |||

| Study | 158.2 | 11.679 | 149.845 | 166.554 | 141 | 175 | |||

| X2 | Dentsply | 132.6 | 33.583 | 108.576 | 156.623 | 102 | 183 | 17.853 | 0 |

| Simulated | 92.7 | 11.719 | 84.316 | 101.083 | 79 | 111 | |||

| Study | 78.4 | 7.7917 | 72.826 | 83.974 | 69 | 90 | |||

Further comparisons were performed using Tukey's HSD test and the results for X1 files groups revealed high significant difference (P<0.001) between all groups. For X2 files groups results revealed a significant difference (P<0.05) in values between Dentsply and Simulated group, and high significant difference between Dentsply and study groups, while no significant difference (P>0.05) in values between simulated and study group, which shown in Table 9 [26].

Table 9: Tukey HSD among groups of each type of pro taper next files.

| Protaper Next | Mean difference | P-Value | 95% Confidence interval | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LB | UB | |||||||||

| X1 | Dentsply | Simulated | 64.9 | 0.000 (H.S) | 51.867 | 77.933 | ||||

| Study | 34.9 | 0.000 (H.S) | 21.867 | 47.933 | ||||||

| Simulated | Study | -30 | 0.000 (HS) | -43.033- | -16.967 | |||||

| X2 | Dentsply | Simulated | 39.9 | 0.001 (S) | 16.589 | 63.21 | ||||

| Study | 54.2 | 0.000 (H.S) | 30.889 | 77.51 | ||||||

| Simulated | Study | 14.3 | 0.297 (N.S) | -9.01 | 37.61 | |||||

Discussion

The instruments used in the presented work have been chosen due to the fact that they all followed the same instrumentation scheme. In comparison to PTN and PTU series, the PTG series exhibited better CF behaviour in this work. The axes of rotation, cross sections, tapering schemes, and metallurgic processing alterations of PTG, PTU, and PTN instruments, on the other hand, differ.

PTG instruments were considered as the most CF-resistant, succeeded by PTN as well as PTU. Also, the thermomechanical treatment related to PTN and PTG instruments might be linked to their high CF resistance. PTG has more flexibility compared to PTU in this work, which is due to the thermal treatment regarding NiTi alloy, which promotes flexibility and prevents crack propagation through preventing the crystallography slipping. In the case when all other criteria (design, cross section, and so on) are the same, a file that is more flexible might experience a lower amount of the stress for certain strain, which allow long fatigue lifetime. In addition, the number of the loading cycles necessary for developing a fatigue crack and propagating the crack to a critical size is the component's fatigue life [8]. Instrument morphology is thought to be a considerable predictor of CF behaviour, which could indicate why PTG instruments have a higher CF resistance than PTN instruments. A few researchers have found that instrument design isn't a significant factor of CF resistance [17]. While others indicated that the cross-sectional design of different files is a major determinant of CF resistance [9,11,12,18,19]. Instruments with a triangle cross-section showed stronger fatigue resistance in comparison to those with square cross-section, according to [20].

CF resistance of various NiTi rotary systems has been compared in many researches. Utilizing a 3-point bending device at 40 curvature and radius of 6 mm, Hieawy, et al. investigated the CF resistance regarding PTG as well as PTU instruments of sizes S1 to F3. Their findings have shown that PTG file had a considerably high CF resistance in comparison to PTU files (P<0.001). Despite the fact that the PTU and PTG systems have the same operation and architecture, the instruments' varied manufacturing procedures have a significant impact on their fatigue resistance behaviours and stress-strain distribution patterns. The transformation behaviour related to NiTi alloys is strongly influenced by their thermomechanical treatment. Based on the thermomechanical treatments, the martensitic transformations in the near-equiatomic NiTi alloys could be a single stage transformation (Austenite [A] Marten site [M]) or a 2-phase transformation (A-R-M) [21]. In Ni-rich NiTi alloys, a one-stage transformation A-to-M takes place, then a two-stage transform A-R-M takes place following more heat treatments that results in finely dispersed Ti3Ni4 precipitates in the austenitic matrix [22].

When indicating that an R-phase is one other possible phase of the marten site and the relative preferences regarding R-phase over the marten site in the presence of the fine particles, the transformation from one-stage into two-stage may be understood. This is due to the fact that Ti3Ni4 particles are resisting the development of marten site, related to a substantial deformation of the lattice, yet they resist the creation of R-phase, related too much smaller deformation of the lattice, far less. Although the existence of Ti3Ni4 particles encourages the R-phase formation, the alloy must be cooled further to create marten site. As a result, martensitic transformation takes place in two stages: A-R-M [21]. In the case when stress is applied over a critical threshold, which occurs in the case where the ambient temperature is over the material's Af temperature, pseudo-elasticity or super-elasticity is connected with the phase transformation occurrence regarding NiTi alloy. To employ pseudo-elasticity, the working temperature for standard super-elastic NiTi files should be higher than Af. Actually, the Af temperatures of super elastic NiTi files, such as Pro Taper and Pro File, are below body temperature [8]. The variations in the resistance to fatigue between PTU and PTG files are explained by the occurrence of such variations of the marten site that might be linked to high transformation temperature degrees that have been reported in PTG files. The number of the cycles to the failure in the martensitic NiTi wires could be 100 times high compared to that in stable as well as super elastic austenitic NiTi, according to [22]. PTG has been more adaptable than PTU in this investigation. In the case when all other criteria (design, cross section, and so on) are the same, a higher flexibility file might experience lower level of stress for a certain strain, which allow long fatigue life-time.

The number of the loading cycles that are necessary for developing a fatigue crack and propagating the crack to critical size is the component's fatigue life. In marten site, the mechanism of crack propagation consists of a huge number of extremely branched cracks which propagate slowly. Just some cracks nucleate in super elastic NiTi, and they propagate quickly [23]. Furthermore, in both the PTU and PTG systems, the S2 and S1 files showed high resistance to fatigue failure in comparison with F-1-F-3 files (P<0.001). The results from PTG and PTU series in [6]. Indicated that that S1 PTG had the maximum CF resistance of all files (P less than 0.001); therefore, the higher the level of the strain (typically represented by the instrument radius ratio at the point of the breakage to curvature radius), the shorter becomes the fatigue life. In addition, the S-1 PTU files had statistically significantly more sufficient cyclic fatigue resistance in comparison to F2, F1, and F3 files, according to previous tests. This has been also validated in the current work, which found that as instrument diameter increased, both PTU and PTG showed decreased fatigue resistance [24]. In our study, for pro taper universal results, Dentsply showed the highest mean values than simulated and study files for S1 files, while for F1 files showed least mean difference but no significant difference for S2 files and, for pro taper gold results Dentsply showed no significant difference in mean values than simulated files for F1 files, while highest mean values for S2 files and for F1 files, also highest mean values for pro taper next results in both tested files X1 and X2 which might be due to various factors like the manufacturing processes and alloy’s chemical composition [25,26]. Different inclusion particles, such as oxide particles, are incorporated on the metal surface throughout the process of manufacturing. These particles serve as a nucleating site for micro crack propagation [27]. According to cracks propagate perpendicular to the instrument's long direction, and micro voids are occasionally generated on the surface due to the presence of nitrogen, oxygen, carbon and hydrogen [28]. More cracks might form along such faults, and in the case when exposed to unloading and loading of instrument, those areas undergo a phase transition from austentic to martensitic, affecting the instrument's mechanical properties [29]. While S1 study files showed higher mean values than simulated files for both pro taper universal and pro taper gold groups which attributed to the curvature area in the simulated canal is (5 mm) from the apex and plane part of study file is (8 mm) from the apex of the file making it more resistant to fracture because its plane (unthreaded) in which the area between the spiral and adjacent spiral act as a weak area which is more susceptible to fracture, this agree with One of the researches had shown that dentinal debris has been mostly wedged in the narrow radial, land-type areas and less on convex flute surfaces of the utilized Pro Taper files [27]. Dentinal debris has been found predominantly in metal rollover and on the concave flute surfaces in an examination of used Pro File instruments.

Those dentinal chips can lead to a build-up of tensions, which can lead to NiTi rotary instruments failing clinically. Also, the clinical fracture related to NiTi rotary instruments is thought to be induced primarily by a single overload throughout instrumentation, instead of severe alloy fatigue. Local dentinal chip embedment in machining grooves can produce such overloading [30]. S2 study files indicated no significant difference from simulated files for both pro taper universal and pro taper gold groups which attributed to the curvature area in the simulated canal is (5 mm) from the apex and plane part of study file is (3 mm) from the apex so the area at curvature of simulated and study files are both with spirals at this part of the file. F1 study files showed less mean values than simulated files for pro taper universal group which attributed to the area of curvature in simulated canal is (5 mm) from the apex and plane part of study file is (5 mm) from the apex so the curvature of simulated canal at the level of the connection of the plane and spiral part which act as a weak area. This is consistent with Pruett who found that instruments subjected to cyclic fatigue fractured at the centre of curvature or just below it, as previously described [5]. F1 study files showed no significant difference in mean values than simulated files for pro taper gold group in spite of curvature in the simulated canal is (5 mm) from the apex and plane part of study file is (5 mm) from the apex so the curvature of simulated canal at the level of the connection of the plane and spiral part which act as a weak area but the heat treatment of pro taper gold files make the results differ from pro taper universal this is agree with Xu X who said that many factors might impact the stress distribution in NiTi instruments like the alloy, design, and the heat treatment applied throughout manufacturing [31,32].

For pro taper next results, X1 study files showed higher mean values than simulated files which attributed to the curvature area in simulated canal is (5 mm) from the apex and plane part of study file is (8 mm) from the apex of the file making it more resistant to fracture because its without spirals in which the area between the spiral and adjacent spiral act as a weak area which is more susceptible to fracture, Alapati SB showed that depth of flutes or increase the number of spirals of the flute per unit length decrease torsional resistance [27]. X2 study files showed lower mean values than simulated files which may be attributed to that it is with (8 mm) with flutes from the apex and the remaining (8 mm) of the shaft is plane without flutes which affect the flexibility of the file and loose its eccentric rotation of the pro taper next which shows a rectangular cross-section design with regard to superior strength as well as excellent asymmetric rotary motion which enhances the effectiveness of canal shaping as indicated via the manufacturer. Furthermore, they are created with the use of M-Wire NiTi for enhancing the flexibility and cyclic fatigue resistance of files (Dentsply Maillefer, Ballaigues, Switzerland).

Conclusion

The PTG instruments were most resistant to CF, followed by PTN and PTU. The higher CF resistance of the PTG and PTN instruments can be attributed to the thermomechanical treatment of these instruments. For PTU and PTG files groups, for S1 and S2 files making the non-active part plane will increase CF resistance while for F1 files will decrease CF resistance. For PTN files groups, for X1 files making the non-active part plane will increase CF resistance while for X2 files will decrease CF resistance.

References

- Walia H, Brantley W, endodontics HGJ, et al. undefined An initial investigation of the bending and torsional properties of Nitinol root canal files. J Endodontics 1998; 14: 346-351.

- Hulsmann M, Peters OA, Dummer PMH, et al. Mechanical preparation of root canals: shaping goals, techniques and means. Endod Top 2005; 10:30-76.

- Anous W, Al-Ashry S, Ali M, et al. Effect of different kinematic cutting motion in multiple versus single-file concept on dentinal crack formation: An in vitro J Int Oral Heal 2020; 12:30-40.

[Crossref][Google Scholar][Pubmed]

- Elnaghy AM, Elsaka SE. Assessment of the mechanical properties of ProTaper next nickel-titanium rotary files. J Endod 2014; 40:1830-1834.

- Pruett O, John P, David J, et al. Scientific Articles Cyclic Fatigue Testing of Nickel-Titanium Endodontic Instruments 1997; 23:77-85.

- Hieawy A, Haapasalo M, Zhou H, et al. Phase transformation behavior and resistance to bending and cyclic fatigue of ProTaper Gold and ProTaper Universal instruments. J Endodontics 2021; 41:1134-1138.

- Plotino G, Grande NM, Cordaro M, et al. A Review of Cyclic Fatigue Testing of Nickel-Titanium Rotary Instruments. J Endodontics 2009; 35: 1469-1476.

- Shen Y, Zhou H-M, Zheng Y-F, et al. Current Challenges and Concepts of the Thermomechanical Treatment of Nickel-Titanium Instruments. J Endod 2013; 39:163-172.

- Haikel Y, Serfaty R, Bateman G, et al. Dynamic and cyclic fatigue of engine-driven rotary nickel-titanium endodontic instruments. J Endod 1999; 25:434-440.

- Ruddle C, Machtou P, today JW-D, et al. undefined Endodontic Canal Preparation: New Innovations in Glide Path Management and Shaping Canals. Accessed j 2021.

- Plotino G, Grande NM, Sorci E, et al. A comparison of cyclic fatigue between used and new Mtwo Ni-Ti rotary instruments. Wiley Online Libr 2006; 39:716-723.

- Gambarini G, Grande N, Plotino G, et al. Fatigue resistance of engine-driven rotary nickel-titanium instruments produced by new manufacturing methods. 2008; 34:1003-1005. .

- Capar I, Kaval M, Ertas H, et al. Comparison of the cyclic fatigue resistance of 5 different rotary pathfinding instruments made of conventional nickel-titanium wire, m-wire, and controlled memory wire. 2015; 41:535-538.

- Mohammed MK, Al-Ahmari A, Umer U, et al. Multiobjective optimization of Nd:YAG direct laser writing of microchannels for microfluidic applications. Int J Adv Manuf Technol 2015; 81:1363-1377.

- Correia J de O, Pedrosa B, Engineering PR, et al. Fatigue strength evaluation of resin-injected bolted connections using statistical analysis. 2017; 3:795-805.

- Correia J, Blason S, ADJ-EF, et al. Fatigue life prediction based on an equivalent initial flaw size approach and a new normalized fatigue crack growth model. 2016; 69:15-28.

- heung GSP, Darvell BW. Low-cycle fatigue of NiTi rotary instruments of various cross-sectional shapes. Int Endod J 2007; 40:626-632.

- Ray JJ, Kirkpatrick TC, Rutledge RE, et al. Cyclic fatigue of endo sequence and k3 rotary files in a dynamic model. 2007; 33:1469-1472

- Tripi T, Bonaccorso A, Surgery GC-O, et al. Cyclic fatigue of different nickel-titanium endodontic rotary instruments. 2006; 102:106-114.

- Cheung GSP, Zhang EW, Zheng YF, et al. A numerical method for predicting the bending fatigue life of NiTi and stainless steel root canal instruments. Int Endod J 2011; 44:357-361.

- Sarkar S, Ren X, Otsuka K, et al. Evidence for strain glass in the ferroelastic-martensitic system Ti50-xNi50+x. Phys Rev Lett 2005; 95.

- Figueiredo A, Modenesi P, Fatigue VB-IJ, et al.Low-cycle fatigue life of super elastic niti wires. 2009; 31:751-758.

- McKelvey AL, Ritchie RO. Fatigue-crack growth behavior in the superelastic and shape-memory alloy nitinol. Metall Mater Trans A. 2001; 32:731-743.

- Perez-Higueras JJ, Arias A, de la Macorra JC, Peters OA. Differences in cyclic fatigue resistance between ProTaper Next and ProTaper Universal instruments at different levels. J Endod 2014; 40:1477-1481.

- Kuhn G, Jordan L. Fatigue and mechanical properties of nickel-titanium endodontic instruments. J Endod 2002; 28:716-720.

- Marending M, Lutz F, Barbakow F, et al. Scanning electron microscope appearances of Light speed instruments used clinically: A pilot study. Int Endod J 1998; 31:57-62.

- Alapati S, Brantley W, Svec T, et al. Proposed role of embedded dentin chips for the clinical failure of nickel-titanium rotary instruments. Elsevier 2021.

- Alapati S, Brantley W, Svec T, et al. Sem observations of nickel-titanium rotary endodontic instruments that fractured during clinical use. Elsevier 2021.

- Miyai K, Ebihara A, Hayashi Y, et al. Influence of phase transformation on the torsional and bending properties of nickel-titanium rotary endodontic instruments. Int Endod J 2006; 39:119-126.

- Madarati AA, Watts DC, Qualtrough AJE, et al. Factors contributing to the separation of endodontic files. Br Dent J 2008; 204:241-245.

- Xu X, Eng M, Zheng Y, et al. Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sections. J Endod 2006; 32:372-375.

- Nitinol and stainless steel: property comparison.

Author Info

Ali S Abu Naila* and Hussain F Al-Huwaizi

Department of Conservative and Esthetic Dentistry, University of Dentistry-Baghdad, IraqReceived: 20-May-2022, Manuscript No. JRMDS-22-43723; , Pre QC No. JRMDS-22-43723; Editor assigned: 23-May-2022, Pre QC No. JRMDS-22-43723; Reviewed: 06-Jun-2022, QC No. JRMDS-22-43723; Revised: 25-Jul-2022, Manuscript No. JRMDS-22-43723; Published: 01-Aug-2022