Research - (2022) Volume 10, Issue 3

Effect of Addition of the Intrinsic Pigment on the Some Physical and Mechanical Properties of Modified Silicone Elastomer with Nano Yttrium Oxide

Zainab H Al-Naser* and Faiza M Abdul-Ameer

*Correspondence: Zainab H Al-Naser, Department of Prosthodontics, College of Dentistry, University of Baghdad, Iraq, Email:

Abstract

Introduction: Silicone elastomers have a long history of widespread use in the creation of maxillofacial and other types of prosthetic devices, particularly in situations where soft tissue and anatomic (shape) reconstruction are required. Despite the fact that they are used all over the world, they aren't ideal in every way. The long life of maxillofacial prostheses is based on the material used in the prosthesis also the patient's attitude and feeling toward the prosthesis, and it can be directly related to the effectiveness of the prosthesis when it comes to achieving its objectives. Aim of the study: To evaluate the effect of the addition of an optimum weight percentage of a mixture of the yttrium oxide nanoparticles and intrinsic pigment (burnt sienna) on some physical and mechanical properties of room-temperature-vulcanized (RTV) VST50HD maxillofacial silicone elastomer, including (tear strength, thermal conductivity, and surface hardness). Materials and methods: Yttrium oxide nano particle was add in 0.5 wt. % and functional intrinsic pigment burnt sienna was adding in 0.2 wt. % and 0.3 wt. % to maxillofacial silicone. The maxillofacial silicone material was mixed and cured according to the manufacturer's instructions, and there were ninety specimens produced. The specimens had been divided into three groups based on these tests (tear strength, thermal conductivity and Shore A hardness), each group contains thirty specimens, three subgroups were formed from the groups: Group A which is called a control group with no nano filler 0%, whereas groups B and C are experimental groups containing 0.5 wt.% of nano filler and 0.2 wt. % functional intrinsic pigment burnt sienna and 0.5 wt.% of nano filler and 0.3 wt.% functional intrinsic pigment burnt sienna respectively. The study's obtained data was statistically examined using analysis of variance (one-way ANOVA) and Tukey Honestly significant difference (Tukey's HSD) test (significant level at p>0.05). Results: The tear strength test and thermal conductivity test show highly significant increase between group (A) and group (B) (P<0.01), a highly significant increase between group (A) and group (C) (P<0.01). In hardness test the result show highly significant increase happen between group (A) and group (B) (P<0.01), and non-significant increase in between group (A) and group (C) (P<0.05). Conclusion: The addition yttirum oxide nano particles and functional intrinsic pigment burnt sienna improve tear strength, thermal conductivity. As well as there was increased in the hardness but still with the clinical limit.

Keywords

Silicone, Maxillofacial prosthesis, VST50HD, Yttirum oxide, Nano filler, Intrinsic pigment

Introduction

Maxillofacial prosthesis generally described as any prosthesis that is utilized to replace a portion or the entirety of any stomatognathic or craniofacial component [1]. Trauma, neoplasm therapy, or congenital deformity can all result in facial deformities. Insufficient of the material for facial restorations, moveable the tissue below it, difficulty and complexity in keeping large prostheses, and the patient's ability to accept and like the final result limit the prosthodontics [2]. Silicones were initially introduced in 1946, but were not used until Barnhart did it first time in (1960) for extra-oral prosthesis and gained popularity in comparison to other materials but have certain problematic qualities. As a result, an appropriate maxillofacial material must be discovered [2]. Silicones, commonly known as polydimethyl siloxane, have proven to be the most successful material for maxillofacial prosthetics to date, and new advancements are being conducted to this material to overcome its limitations as they become available. These materials have gained popularity over other materials because they maintained a wide range of good physical properties over a wide range of temperatures, have easy manipulate, being chemically inert, have a low degree of toxicity and they have been thermal and oxidative stability, among other characteristics. In addition, they can be dyed both intrinsically and extrinsically to give them the appearance that is more lifelike and natural, if desired [3]. In recent studies nano oxide fillers have been frequently used as silicone elastomers additives, because they are stiffer than the polymeric matrix. The nano particles high surface area and also high surface energy make them more reactive and enable them to be integrated into the polymer's backbone, have been found in several experiments to improve the mechanical properties of the polymeric matrix [4,5]. One of the rare earth elements is yttrium oxide nano particles which had been recently used as reinforcing element for acrylic denture base resins, composites, zirconia, implants and dental resin cement alone or in combination with other additives and shows varying changes in the properties as water absorption, thermal conductivity, hardness and tensile strength [6]. An aesthetically pleasing and comfortable maxillofacial prosthesis alleviates many of the patient's fears and may even improve his or her quality of life [7]. When it comes to manufacturing an effective maxillofacial prosthesis, pigmentation and coloring are critical considerations. In clinical practice, it is common to use both intrinsic and extrinsic coloring to match the prosthesis to the surrounding human tissue. Extrinsic coloring is more susceptible to environmental circumstances and handling than intrinsic coloring, which establishes the basic color and translucency of the mixture but is more likely to change the structure and qualities of the mixture when compared to extrinsic coloring [8,9]. The optimal elastomer-colorant combination should not only provide clinically acceptable aesthetics, but also maintain aesthetically and physical characteristics in perpetuity, or at least until the patient's tissues have changed to the point where the prosthesis fits [10]. The requirement for materials with higher properties remain to be necessary and studies is continuous to establish a new maxillofacial polymeric material that has enhanced mechanical properties in spite of a number of advancement were realized in maxillofacial materials before years [11,12].

Materials and Methods

Yttrium oxide nano particles (Y2O3) 30- 45nm (SkySpring Nanomaterials, USA) and Functional intrinsic pigment (FI) pigment (burnt sienna) (Factor II Inc., Lakeside, USA) have been integrated into vulcanized silicone VST50HD that is used at room temperature. (Factor II Inc. Lakeside, USA). There are a sum of 90 specimens have been made, and the specimens were categorized into three groups based on the tests (tear strength, thermal conductivity, and Shore A hardness), with each group containing 30 specimens; group A was with 0% of nano filler called the control group, while groups B and C were with 0.5 wt.% of nano filler and 0.2 wt. % functional intrinsic pigment burnt sienna and 0.5 wt.% of nano filler and 0.3 wt.% functional intrinsic pigment burnt sienna respectively called experimental groups.

Pilot study

Pilot study will be done on 2 steps: First step different percentage of nano particles added to maxillofacial silicone and experimenting their effect, then the most appropriate percentage that improve tear strength and thermal conductivity will be selected. Second step different percentage of pigments is incorporated in a modified maxillofacial silicone with nano particles and experimenting their effect on tear strength and thermal conductivity. After selection of most appropriate two percentages of intrinsic pigments on a modified maxillofacial silicone from the pilot study new specimens will be prepared and they will be used in the main study using these tests (tear strength, thermal conductivity and surface hardness).

Preparing the mold

Designing the mold was done using computer software type (Auto CAD 2015 (Autodesk Inc., San Rafael, CA (United States of America)), and the pieces were cut using a laser engraving cutting machine. Acrylic sheets with thicknesses ranging from 2±0.05 mm to 6±0.05 mm were utilized to create the proper mold size according on the parameters required for each test [13].

Fabrication and conditioning of the specimens

Specimens were created for silicone elastomer and divided into two subgroups, which were referred to as control and experimental subgroups. The control subgroup's specimens were prepared and mixed at a base to catalyst ratio of 10:1 (w/w) in accordance with the manufacturer's instructions. A vacuum mixer (Dentaurum airvac, Germany) was put to utilized to mix the mixture for a period of 5 minutes and the device at a speed of 360 rpm and a vacuum of -10 bar [14,15]. All of the experimental subgroup’s specimens were be mixed in the similar way to the control subgroups, with the similar mixing ratio, but with the addition a mixture of nano- Y2O3 filler by a clean spatula and intrinsic burnt sienna color pigment which was added as drops from the pigment dropper-type bottle after it had been shaken. The procedure of mixing was done by weighing 0.5 wt% nano-Y2O3 filler + 0.2 wt% intrinsic pigment and also 0. 5 wt% nano- Y2O3 filler + 0.3 wt% intrinsic pigment for the RTV elastomers. The silicone elastomer base had been added and mixed without vacuum for (3) minutes by utilized the vacuum mixer to avoid powder suction, then turned on the vacuum mixer for the following (7) minutes at (360) rpm speed with a vacuum value of (-10) bar to remove any air bubbles [16,17]. The silicone elastomer's catalyst was spread in numerous regions, and the mixture had been thoroughly mixed under vacuum for 5 minutes [15,18]. Following the manufacturer's recommendations, the task of the mixing the silicone with additives and pouring was completed at controlled temperature of 23°C±2°C with a relative humidity (RH) of roughly 50%±10% [19]. The VST50HD elastomer was set for nearly overnight. In order to avoid straining, the specimens were very carefully removed from their molds and preserved in an air-conditioned room in a lightproof box (custom-made). The temperature should be kept within the acceptable range degree of 10°C–30°C while on storage, and the RH value was approximately 80% [19]. In order to prepare for testing, the specimens were preconditioned for 24 hours at temperature 23°C ± 1°C and humidity 50% ± 10% RH [19].

Experimental tests

Test for tear strength

In accordance with ISO 34-1 guidelines [20].

The specimens had been able to tested by using the universal testing machine clamps (Zwick roell, Germany). The tear strength specimens were the type C tear specimens. For the purpose to calculating the tear strength, the following formula is being used:

Tear strength = F/D,

In this equation, F symbol is mean the value of final force needed to breakdown the specimens in kilonewtons, D symbol is mean the value of average thickness of the specimens in meters [20].

Test for Shore A hardness

A procedure that was done in accordance with ISO 7619-1, 2010 guidelines [21]. By utilizing a digital device Shore A durometer which have a blunt tip indenter of (1.25mm) diameter with digital scale (0 to 100) to perform the hardness test. Within each specimen, there are five points that were denoted by the symbol (6 mm) distance apart in the space between them and the lateral borders sideways [22].

Test for thermal conductivity

The test was done by using an apparatus which is a modification apparatus of the standard Lees’ disk method that use for the measurement of thermal conductivity done by the exact plane parallel plate technique. The specimens thickness which was equal to the diameter of copper plates in this study was approximately 3 mm in thickness and 40 mm in diameter according to specification of instrument [23].

Statistical analysis

The findings of this study were evaluated and tested by utilizing SPSS (statistical package for social sciences, version 24) software, with one-way ANOVA (analysis of variance) being used to compare the mean values of the groups investigated. And the significance of the difference between each of the two tested groups was determined by using a post hoc test (Tukey HSD). P values of >0.05 were considered as statistically non-significant (NS), P values of ≤0.05 were considered as statistically significant (S), and P values of ≤0.01 were considered as highly significant (HS).

Results

Tear strength test results

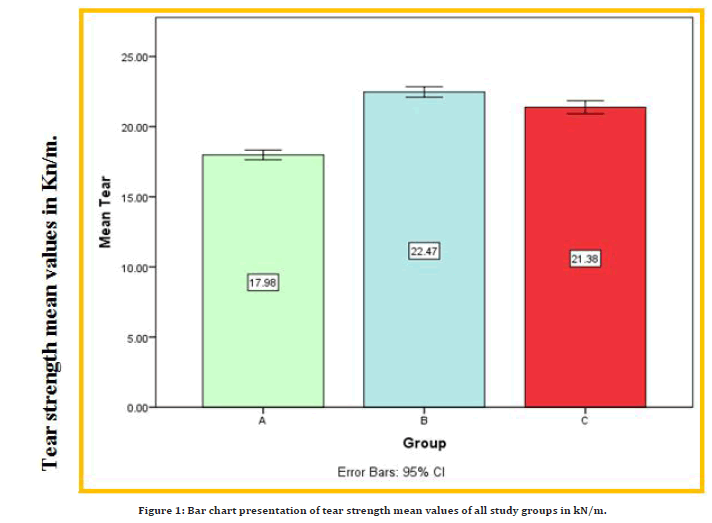

Both (B) and (C) experimental groups exhibited greater mean tear strength values than group (A) (control) (17.980 kN/m), with experimental group (B) having the highest mean value of (22.470 kN/m) followed by group (C) (21.380 kN/m), as seen in Figure 1. Using one-way analysis of variance (ANOVA), a statistical test of tear strength between groups revealed a highly significant difference at p<0.01 (Table 1). The Tukey Honestly Significant Difference (Tukey's HSD) test used to compare between the mean values of groups (Table 2). The test revealed highly significant difference between group (A) and group (B) at p >0.01, a highly significant difference between group (A) and group (C) and a highly significant difference between group (B) and group (C) at p<0.01.

Figure 1: Bar chart presentation of tear strength mean values of all study groups in kN/m.

| Sum of squares | df | Mean Square | F | P value | |

|---|---|---|---|---|---|

| Between Groups | 109.694 | 2 | 54.847 | 179.87 | 0.0001 (HS) |

| Within Groups | 8.233 | 27 | 0.305 | ||

| Total | 117.927 | 29 |

Table 1: Statistical analysis of tear strength by utilizing one-way ANOVA.

| Tukey HSD test for tear strength | |||

|---|---|---|---|

| (I) Groups | (J) Groups | Mean Difference (I-J) | p value |

| Group A | Group B | -4.49 | 0.0001 (HS) |

| Group C | -3.4 | 0.0001 (HS) | |

| Group B | Group C | 1.09 | 0.0001 (HS) |

Table 2: Multiple comparisons between groups for tear strength test using Tukey Honestly significant difference (Tukey HSD).

Thermal conductivity test results

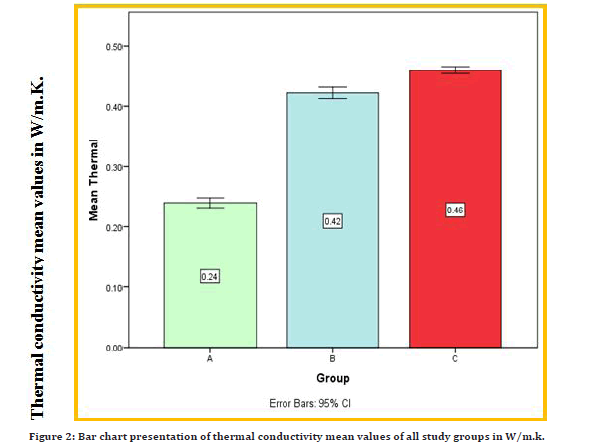

Both (B) and (C) experimental groups exhibited greater mean thermal conductivity values than group (A) (control) (0.240 W/m.k), with experimental group (C) having the highest mean value (0.460 W/m. k), followed by group (B) (0.422 W/m. k), as shown in Figure 2.

Figure 2:Bar chart presentation of thermal conductivity mean values of all study groups in W/m.k.

Using one-way analysis of variance (ANOVA) statistical test of thermal conductivity among groups revealed a highly significant p <0.01 (Table 3). In compression between the mean values of the groups, Tukey Honestly significant difference (Tukey's HSD) test was implied (Table 4). The test revealed a highly significant difference between group (A) and group (B) p <0.01, a highly significant difference between group (A) and group (C) and a highly significant difference between group (B) and group (C).

| Sum of Squares | Df | Mean Square | F | P value | |

|---|---|---|---|---|---|

| Between Groups | 0.28 | 2 | 0.14 | 1111.18 | 0.001 |

| Within Groups | 0 | 27 | 0 | ||

| Total | 0.28 | 29 |

Table 3: Statistical analysis of thermal conductivity by utilizing one-way ANOVA.

| Tukey HSD test for thermal conductivity | |||

|---|---|---|---|

| (I) Groups | (J) Groups | Mean Difference (I-J) | p value |

| Group A | Group B | -0.182 | 0.0001 (HS) |

| Group C | -0.22 | 0.0001 (HS) | |

| Group B | Group C | -0.038 | 0.0001 (HS) |

Table 4: Multiple comparisons between groups for thermal conductivity test using Tukey Honestly significant difference (Tukey HSD).

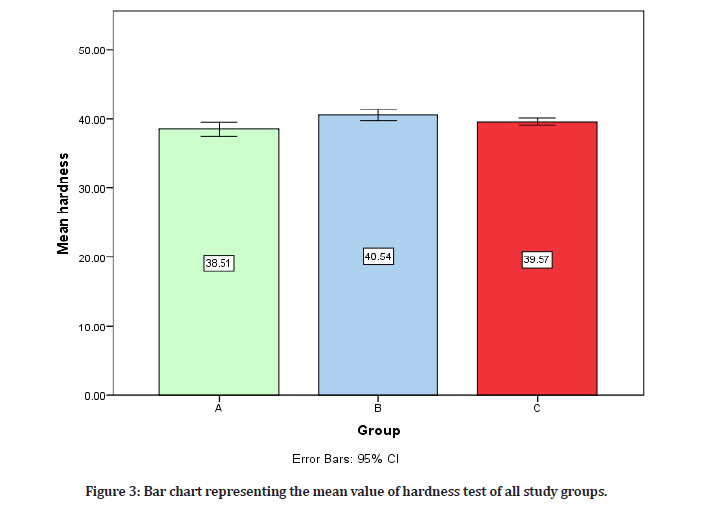

Shore A hardness test results

Both (B) and (C) experimental groups had greater mean hardness values than group (A) (control) (38.510), with experimental group (B) having the highest mean value (40.540), followed by experimental group (C) (39.570), as shown in Figure (3). Using one-way analysis of variance (ANOVA) statistical test of hardness among groups revealed a highly significant p <0.01 (Table 5). In order to compare between the mean values of the groups, Tukey Honestly significant difference (Tukey's HSD) test was implied (Table 6). The test revealed highly significant difference between group (A) and group (B) p <0.01, non-significant difference between group (A) and group (C) and a non-significant difference between group (B) and group (C).

| Sum of Squares | df | Mean Square | F | P value | |

|---|---|---|---|---|---|

| Between Groups | 20.618 | 2 | 10.309 | 8.107 | 0.002 (HS) |

| Within Groups | 34.334 | 27 | 1.272 | ||

| Total | 54.952 | 29 |

Table 5: Statistical analysis of hardness by utilizing one-way ANOVA.

| Tukey HSD test for hardness | |||

|---|---|---|---|

| (I) Groups | (J) Groups | Mean Difference (I-J) | p value |

| Group A | Group B | -2.03 | 0.001 (HS) |

| Group C | -1.06 | 0.108 (NS) | |

| Group B | Group C | 0.97 | 0.151 (NS) |

Table 6: Multiple comparisons between groups for hardness test using tukey honestly significant difference Tukey(HSD).

Figure 3: Bar chart representing the mean value of hardness test of all study groups.

Discussion

Manufacturers provide only the mechanical properties of their silicone material without the addition of opacifiers or pigments, which is not reflective of how silicone elastomers are utilized in extra-oral maxillofacial prosthesis. Therefore, when selecting a material for an extra-oral maxillofacial prosthesis, clinicians should exercise caution when relying on manufacturer's specifications [24]. To acquire a certain level of reinforcement that significantly improves the mechanical properties, the addition of fillers considered very needful. The quantity of the filler use, filler parameters like (particle size or specific surface area, structure, and surface activity), polymer properties and manufacturing circumstances are all taken into consideration. The reinforcement is influenced by each of these parameters to a varying degree [25,26]. When it comes to color qualities, a maxillofacial prosthetic material must be able to receive and preserve intrinsic and extrinsic colors, and the aesthetic and mechanical strength of the prosthesis cannot be altered by sunlight or other environmental variables [27].

Tear strength

Tear strength is a measure of resistance to tearing forces and is crucial for the prosthesis's thin edges that merge with facial tissues [28]. The test result of tear strength indicates a highly significant increase in tear strength when nano Y2O3 and intrinsic pigment burnt sienna are added to VST50HD (RTV) silicone in both percentages in experimental groups in comparison to the control group and with a highly significant difference between them. This is demonstrated physically by the interaction of nanoparticles with the silicone matrix. Trapped networks formed due to the nanoparticles' capacity to combine in three dimensions, producing filler meshes within the polymer matrix. These trapped networks participate in both hindering the movement of polymer segment against the nanoparticles surface and preventing the movement of other polymer chains against each other; this changes the overall network density and causes a marked increase in polymer stiffness which will increase the tear strength [29,30]. The highly significant increase in tear strength that occurred when burnt sienna (FI) was added it could be because of the liquid colorant’s action as a plasticizer [31]. It is also possible that the increase in tear strength observed after the integration of intrinsic pigments is may be due to the intrinsic pigments acting as impurities in the catalyst, that reducing the degree of cure. And the reduction of curing may increase the tear strength [32]. When the intrinsic pigment burnt sienna proportion is 0.3% by weight, the tear strength decreases due to the increased degree of cross-linking was most likely due to the restricted segmental mobility of chains, which resulted in massive stress concentrations. The stresses are unable to be dispersed, resulting in tearing of the new material [33].

Thermal conductivity

The possibility to estimate the rate at which heat can be transmitted across a particular crosssectional area of the specimens of material within a specific time interval known as thermal conductivity [34]. The results of thermal conductivity test reveal that after the addition of nano Y2O3 and intrinsic pigment burnt sienna to VST50HD (RTV) in experimental groups when it compared to the control group, there was a highly significant increase in heat conductivity with highly significant increase between them. The structure of the material determines the heat transport method and thus thermal conductivity. While heat is conducted through free electrons in metals, it is conducted through phonons or the lattice waves created by the atoms' vibrational energy in non-metallic materials such as polymers [35,36]. Interfacial physical contact between polymer and filler is crucial for a twophase system such as a polymer/filler composite, as phonons play a significant role in determining heat conductivity via their mean free pathways [37,38]. Also this increase is due to the addition of functional intrinsic pigment burnt sienna because the chemical type is inorganic iron oxide and the chemical formula is Fe2O3 Calcined ferric oxide which has a thermal conductivity higher than silicone (0.1 to ~ 5 W/ (m.k) [39].

Shore A hardness

Hardness is the resistance of the material to the plastic deformation; the hardness measured by indentation load, and measures the softness of the material [40]. It was suggested that the hardness of maxillofacial silicone prosthesis must stay within the range between 10-45 shore A to be clinically applicable depending on the missing facial part [41,42]. The result of hardness test findings that after the addition of nano Y2O3 and intrinsic pigment burnt sienna to VST50HD (RTV) silicone indicate a highly significant increase in hardness in experimental groups in compression to control group, with a non-significant increase between them. The increase was within the acceptable limits. Filler to filler binding increases hardness by filling the inter-aggregate gaps between polymer chains, making them smaller, this increases rigidity of the polymer to resist penetration [43]. The limited increase of silicone and then decrease the hardness after the percentage of functional intrinsic pigment increase to 0.3 wt. % is may be because the polymerization process of the silicone material was affected by the addition of intrinsic pigment, leading to decreased in the hardness [44].

Conflict of Interest

No.

Source of Funding

Self-funded.

Ethical Clearance

Not required.

References

- https://www.academyofprosthodontics.org/lib_ap_articles_download/GPT9.pdf

- Bansal S, Khindria SK, Kansal M. Maxillofacial prosthetic materials. J Indian Prosthodont Soc 2009; 9:2-5.

- Mitra A, Choudhary S, Garg H, et al. Maxillofacial prosthetic materials-an inclination towards silicones. JCDR 2014; 8:8- 13.

- Han Y, Kiat-amnuay S, Powers JM, et al. Effect of nano-oxide concentration on the mechanical properties of a maxillofacial silicone elastomer. J Prosthet Dent 2008; 100:465-73.

- Zayed SM, Alshimy AM, Fahmy AE. Effect of surface treated silicon dioxide nanoparticles on some mechanical properties of maxillofacial silicone elastomer. Int J Biomater 2014; 2014:1-7.

- Gharkan MR, Khalil BI, Ali AH, et al. Study of some properties for cold-curing acrylic resin reienforced with nano yttrium oxide. Iraqi J Mech Materials Eng 2018; 18:137-45.

- Wiens JP, Wiens RL. Psychological management of the maxillofacial prosthetic patient. In: Clinical maxillofacial prosthetics 1st Edn 2000; 1-13.

- Seelaus R, Troppmann RJ. Facial prosthesis fabrication: Technical aspects. In: Clinical maxillofacial prosthetics 1st Edn 2000; 245-64.

- Han Y, Zhao Y, Xie C, et al. Color stability of pigmented maxillofacial silicone elastomer: Effects of nanooxides as opacifiers. J Dent 2010; 38:100-105.

- Gonzalez JB. Polyurethane elastomers for facial prosthesis. J Prosthet Dent 1978; 39: 179-87.

- Al-Obaidi KA, Ali MM. The influence of halloysite nanotube addition on some properties of room temperature vulcanized maxillofacial silicone before and after simulated aging. Indian J Public Health Res Develop 2019; 10.

- Abdul-Ameer FM. Impact of a mixture of nanofiller and intrinsic pigment on tear strength and hardness of two types of maxillofacial silicone elastomers. Dent Res J 2020; 17:251-7.

- Yeh HC. Effect of silica filler on the mechanical properties of silicone maxillofacial prosthesis. PhD diss., Indiana University School of Dentistry 2014.

- Abdullah HA, Abdul-Ameer FM. Evaluation of some mechanical properties of a new silicone material for maxillofacial prostheses after addition of intrinsic pigments. Saudi Dent J 2018; 30:330-336.

- Shihab NM, Abdul-Ameer FM. Studying some mechanical properties of maxillofacial silicone elastomer before and after incorporation of intrinsic pigments and artificial aging. F D J 2018; 4:244-52.

- Tukmachi M, Moudhaffer M. Effect of nano silicon dioxide addition on some properties of heat vulcanized maxillofacial silicone elastomer. J Pharm Biol Sci 2017; 12:37-43.

- Al-Mohammad YN. Evaluation the effect of nano yttrium oxide addition on the mechanical properties of room temperature-vulcanized maxillofacial silicone elastomers. Indian J Forensic Med Toxicol 2020; 14:743.

- Shakir DA, Abdul Ameer FM. Effect of nano titanium oxide addition on some mechanical properties of silicone elastomers for maxillofacial prostheses. J Taibah Univ Med Sci 2018; 13:281-90.

- https://www.iso.org/standard/70323.html

- https://www.iso.org/standard/50751.html

- https://www.iso.org/standard/50756.html

- Hatamleh MM, Watts DC. Mechanical properties and bonding of maxillofacial silicone elastomers. Dent Mater 2010; 26:185-91.

- Price D. M, Jarratt M. Thermal conductivity of PTFE and PTFE composites. Thermochimica Acta 2002; 393.

- Nguyen CT, Chambers MS, Powers JM, et al. Effect of opacifiers and UV absorbers on pigmented maxillofacial silicone elastomer, part 2: mechanical properties after artificial aging. J Prosthet Dent 2013; 109:402-10.

- Yatsuyanagi F, Suzuki N, Ito M, et al. Effects of secondary structure of fillers on the mechanical properties of silica filled rubber systems. Polymer 2001; 42:9523–9529.

- Mahrholz T, Stängle J, Sinapius M. Quantitation of the reinforcement effect of silica nanoparticles in epoxy resins used in liquid composite moulding processes. Compos Part A Appl Sci Manuf 2009; 40:235-43.

- Lewis DH, Castleberry DJ. An assessment of recent advances in external maxillofacial materials. J Prosthet Dent 1980; 43: 426-32.

- Aziz T, Waters M, Jagger R. Analysis of the properties of silicone rubber maxillofacial prosthetic materials. J Dent. 2003; 31:67-74.

- Harper CA. Handbook of plastics, elastomers, and composites: McGraw-Hill New York 2002.

- Zhu AJ, Sternstein SS. Nonlinear viscoelasticity of nanofilled polymers: interfaces, chain statistics and properties recovery kinetics. Compos Sci Technol 2003; 63:1113-26.

- Haug SP, Andres CJ, Moore BK. Color stability and colorant effect on maxillofacial elastomers. Part I: Colorant effect on physical properties. J Prosthet Dent 1999; 81: 418–422.

- Sreeja T. Studies on short nylon fiber-reclaimed rubber/elastomer composites. Ph. D Thesis, Cochin University of Science and Technology 2012.

- Polyzois G, Stafford G D, Winter R. A study of some mechanical properties of an RTV polydimethylsiloxane for extraoral maxillofacial prostheses. Clin Mater 1992; 9:21–29.

- Sakaguchi RL, Powers JM. Craig's restorative dental materials-e-book. Elsevier Health Sciences 2012.

- Godovsky YK. Thermophysical properties of polymers. Springer, New York 1992.

- Hands D. Thermal properties. In: Brown R. Handbook of polymer testing. Marcel Dekker, New York.

- Davis LC, Artz BE. Thermal conductivity of metal-matrix composites. J Appl Phys 1995; 77:4954–4960.

- Dong H, Fan L, Wong C P. Electronic components and technology conference 2005; 1451.

- Zouli N, Said IA, Al-Dahhan M. Enhancement of thermal conductivity and local heat transfer coefficients using Fe2O3/water nanofluid for improved thermal desalination processes. J Nanofluids 2018; 8:1103–1122.

- Liu Q, Shao L, Fan H, et al. Characterization of maxillofacial silicone elastomer reinforced with different hollow microspheres. J Mater Sci 2015; 50:3976–3983.

- Eleni PN, Krokida MK, Polyzois GL, et al. Effect of different disinfecting procedures on the hardness and color stability of two maxillofacial elastomers over time. J Appl Oral Sci 2013; 21:278-283.

- Wang L, Liu Q, Jing D, et al. Biomechanical properties of nano-TiO2 addition to a medical silicone elastomer: The effect of artificial ageing. J Dent 2014; 42:475-83.

- https://www.thefreelibrary.com/Crosslinking+and+reinforcement+of+silica%2Fsilane-filled+rubber...-a0116587114

- Guiotti AM, Goiato MC, dos Santos DM. Evaluation of the shore a hardness of silicone for facial prosthesis as to the effect of storage period and chemical disinfection. J Craniofac Surg 2010; 21:323-7.

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Author Info

Zainab H Al-Naser* and Faiza M Abdul-Ameer

Department of Prosthodontics, College of Dentistry, University of Baghdad, IraqCitation: Zainab H Al-Naser, Faiza M Abdul-Ameer, Effect of Addition of the Intrinsic Pigment on the Some Physical and Mechanical Properties of Modified Silicone Elastomer with Nano Yttrium Oxide, J Res Med Dent Sci, 2022, 10 (3):180-187.

Received: 04-Feb-2022, Manuscript No. JRMDS-22-52368; , Pre QC No. JRMDS-22-52368 (PQ); Editor assigned: 07-Feb-2022, Pre QC No. JRMDS-22-52368 (PQ); Reviewed: 21-Feb-2022, QC No. JRMDS-22-52368; Revised: 25-Feb-2022, Manuscript No. JRMDS-22-52368 (R); Published: 04-Mar-2022