Research - (2021) Volume 9, Issue 12

Effect of Strontium Titanate Nano Powder Addition on Some Mechanical Properties of Room Temperature Vulcanized Maxillofacial Silicone

Ali Saad Ahmed* and Mohammed Moudhaffer Mohammed Ali

*Correspondence: Ali Saad Ahmed, Department of Prosthodontics, College of Dentistry, University of Baghdad, Iraq, Email:

Abstract

Introduction: Although both patients and prosthodontists accept silicone elastomers, additional improvements in their characteristics are needed to increase their performance. During the last decade, chemical researches had been conducted to produce a new generation of polymer with Nano filler integrated into the polymer matrix, resulting in a better material that combines the strength of the Nano filler with the flexibility of the organic polymer

Aims: The study aims to evaluate the effects of strontium Titanate (SrTiO3) nano particles addition on some mechanical properties, including tensile strength, elongation percentage, tear strength, shore A hardness, and surface roughness, of VST-50 maxillofacial silicone elastomer.

Materials and Method: SrTiO3 nanoparticles (average particle size 80-100nm) were introduced into VST-50 platinum silicone elastomer in two weight percentages (1% and 1.5%), as determined by the pilot study, which yielded the most suitable results. A total of 150 specimens were made and divided into control group and two experimental groups. The three groups were then divided into five identical subgroups in accordance with the intentionally performed test. For each subgroup, ten specimens were utilized. The significance level was set at p < 0.05 when statistical analysis was performed on the data.

Results: Both experimental groups (1% and 1.5%) revealed highly significant increase in tensile strength, tear strength and surface roughness. The 1.5% group revealed a highly significant increase in hardness, while 1% groups revealed a non-significant increase. Groups (1% and 1.5%) showed highly significant decrease in elongation percentage.

Conclusion: The addition of SrTiO3 NPs to VST-50 silicone enhanced tear and tensile strength. Surface hardness and roughness increased, but only to clinically acceptable levels. The percentage of elongation was decreased significantly.

Keywords

Strontium Titanate (SrTiO3), VST-50 silicone elastomer, Tear strength, Tensile strength, Elongation percentage

Introduction

Prosthetic devices have been commonly used to restore the defects of congenital or acquired origin such as cancer or trauma. Because surgery may not always be possible due to the location and size of the lesion, the necessity for prosthetic rehabilitation has increased accordingly [1]. Many patients with orofacial defects would regain an active role in society thanks to maxillofacial prosthetic therapy. Furthermore, the maxillofacial prosthesis has proven to be beneficial for them, as its intent is to restore the lost aesthetics while still protecting the remaining tissues [2].

There are different types of materials that can be used to construct maxillofacial prosthetic devices such as chlorinated polyethylene, polyvinyl chloride, polyurethanes, poly methyl methacrylate and polydimethyl siloxane. However, silicone had surpassed other materials as the most popular material for the fabrication of maxillofacial prostheses. This is primarily due to their ease of handling, superior strength, longevity, chemically inert and comfortable to the patient [3].

Prostheses made from silicones should be replaced on a regular basis because their mechanical and physical properties can decline quickly over time, and restoring such prostheses is particularly complex [4]. However, due to their expected half-life and deterioration of mechanical qualities and color stability, silicone maxillofacial prosthesis requires reinforcement [5]. Nanoparticles have integrated into the polymer matrix as fillers during the evolution of the nanoparticle industry to equip a modified polymer defined by enhanced characteristics obtained from the reinforcing action of the nano-oxides [6].

The characteristics and percentage of the filler used with the polymer influence the expected physical and mechanical properties of silicone elastomer. Fillers may be added and modified to create a solid and elastic material that meets the necessary clinical properties. These small additives could improve some of the material’s properties [7].

Strontium Titanate is a strontium and titanium oxide with the chemical formula SrTiO3. It is a material of choice for thin oxide films and superconducting materials. Strontium Titanate nano powder can be used in making scaffolds for bone regeneration [8]. Nano SrTiO3 was used as filler in this study because of its qualities that may enhance some of the properties of maxillofacial silicone at room temperature.

Materials and Method

In this study, strontium Titanate nano powder (Nanoshel, USA) and VST-50 room temperature vulcanized silicone (Factor II Inc., USA) were used.

Pilot study

Various weight concentrations (0.5%, 1%, 1.5%, and 2%) of SrTiO3 were incorporated into VST-50, and tear strength and surface hardness were compared. As a result, the weight percentages of 1% and 1.5 % were chosen because they offered the most suitable results.

Specimen grouping

A total of 150 specimens were made and grouped into control group (0% SrTiO3 referred to as group A) and two experimental groups (1% SrTiO3 referred to as group B and 1.5% SrTiO3 referred to as group C). Finally, every group was further subdivided into five subgroups according to the intentionally performed test.

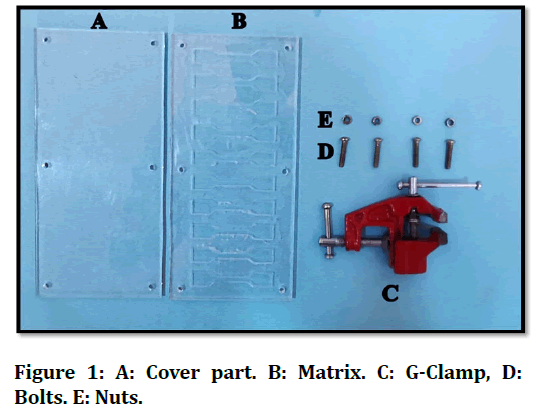

Mold fabrication

Acrylic sheets (2-6 mm) in thickness according to each test were cut by laser engraving machine (JL-1612, Jinan Link Manufacture and Trading Co., Ltd., China). The cutting was performed in accordance with predetermined requirements for every test as determined by computer software Auto CAD 2019 ((Autodesk Inc., San Rafael, CA, USA)). The mold is made up of a base, a matrix and cover, which are held together by bolts and nuts. G- clamps were also used at the edges for further tightening (Figure 1).

Figure 1. A: Cover part. B: Matrix. C: G-Clamp, D: Bolts. E: Nuts.

Mixing

The VST-50 silicone is mixed in a ratio of 10:1(10 parts of base: 1 part of catalyst) according to the manufacturer’s recommendations. Vacuum mixer was used to mix the silicone to prevent air entrapment.

Control group specimens were mixed by weighing the base and catalyst of VST-50 silicone on an electronic balance with 0.000 accuracy (China), then mixing inside a vacuum mixer (Multivac 3, Degussa, Germany) at 360 rpm under - 10 bar pressure for 5 minutes to eliminate air entrapment.

For 1% and 1.5% specimens, the desired concentration of SrTiO3 is weighed on a digital balance and then the base is added. The SrTiO3 and base were mixed inside the vacuum mixer for 3 minutes without evacuation of air to prevent suction of SrTiO3 nano powder. This is followed by mixing the nano powder and base under vacuum for 7 minutes. After that the mix is allowed to cool for 5 minutes, then the catalyst was added, and the mixing was carried out for 5 minutes under vacuum to minimize the possibility of air bubble formation [9].

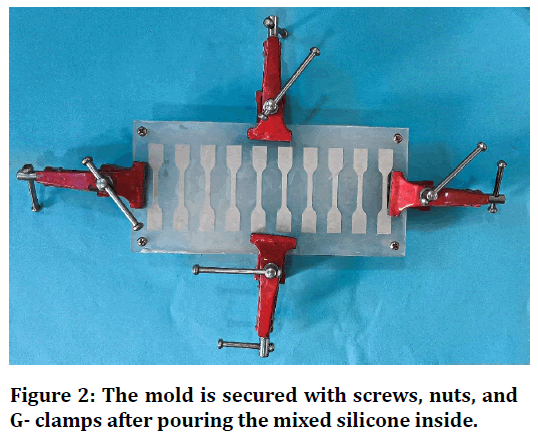

Preparation, finishing and storage of specimens

The mixed material was poured inside the mold with excess material to avoid air bubbles that might form on the specimens as the cover is being placed. After placing the cover on the material, bolts and nuts were fixed and the mold parts were tightened with G-clamps (Figure 2). The mixed silicone was left to be polymerized for 24 hours at room temperature (23°С ± 2°С). After setting of the material, the mold parts are separated, and the specimens are carefully retrieved from the mold. To ensure constant results (prevent the effect of atmosphere that may change the properties) the specimens were stored inside the storage box with indoor and outdoor thermometer. The storage box was made from a closed covering, which was secured by a shielding ring from the inside. The inside part of the box was covered with isolated foil. The storage should be at 20-25°C, 50 ±10% humidity and for 16 hours according to ISO 23529:2016 [10].

Figure 2. The mold is secured with screws, nuts, and G- clamps after pouring the mixed silicone inside.

Testing procedures

Tensile strength and elongation percentages

The specimens were prepared and tested in accordance with ISO 37:2017 [11]. Type 2 dump-bell shaped specimens were fabricated. A digital calliper of 0.01mm accuracy was used to measure the thickness at the midpoint and the ends of the narrow part of the specimen. A universal testing machine (Laryee Technology Co., Ltd., China) was used to test the specimens by holding each specimen symmetrically between the machine grips. The test was conducted at speed of 500mm/min and the highest score and elongation at fracture were calculated. Tensile strength was measured by the following equation:

Tensile strength=Fm/Wt

Where tensile strength measured in (MPa); Fm represents the max force measured in Newton’s; W represents the width (Millimetres), and t is the thickness (mm).

Elongation percentage was measured by:

E%=Lb-Lo/Lo X 100

Where E% is elongation percentage; Lo represents the original length in (mm), and Lb is the length at breakage (mm).

Tear strength

Specimens were fabricated and tested according to ISO 34-1:2015 [12] specification with an apex and two ends. The thickness is 2±0.2mm. A digital caliper was used to measure the thickness at the angled area where tearing may occur. The testing was done using a universal testing machine. The testing speed was 500mm/min. Tear strength test was done by recording the maximum force at break (N/mm).

Tear strength=F/D

Where F represents the maximum force needed to break the specimen in Newtons, and D represents the thickness of each specimen in (mm).

Shore A hardness

The test was done in accordance with ISO 7619-1:2010 [13]. The dimensions are 25mm in length, 25mm in width and 6mm in thickness. Five areas were marked on the surface, six millimeters separated from each other. Shore A durometer (Laizhou Laihua Co., China) with a blunt end and a diameter of 1.25 mm used for testing. The specimen is placed on a flat table, which is raised up by a lever until the indenter contacts the specimen for one second. The hardness at each point was measured, and then the mean of the three measurements was considered as the hardness of the specimen.

Roughness test

Specimens for roughness test were fabricated and tested according to ISO 7619-1: 2010 directions. A Portable digital device with 0.001μm accuracy was used. After placing the specimen on a stable and hard surface, the stylus touches the specimen surface at three areas and travels (11mm) along the surface after touching the initial point. The mean of these three readings was measured and considered as the roughness of the specimen.

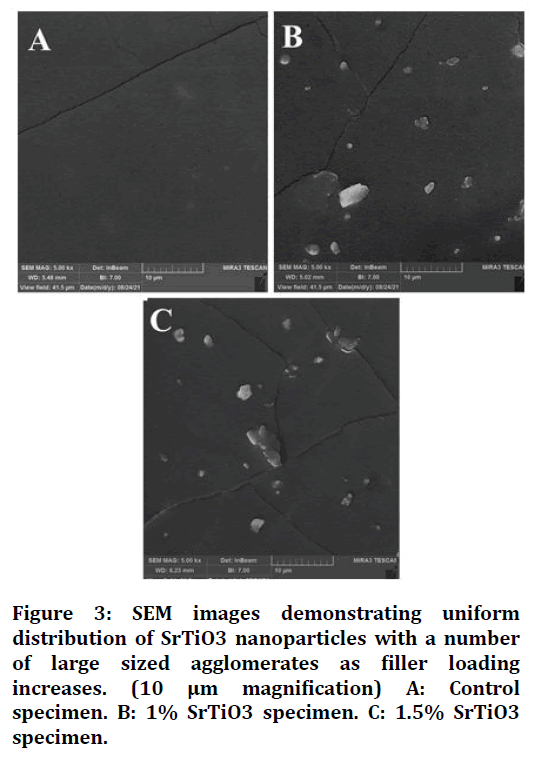

Scanning electron microscope (SEM)

SEM device (TESCAN MIRA3, France) was used to reveal the scattering of strontium Titanate nanoparticles inside the matrix of silicone specimens. Three specimens were used for SEM test, one from the group (A), group (B), and group (C).

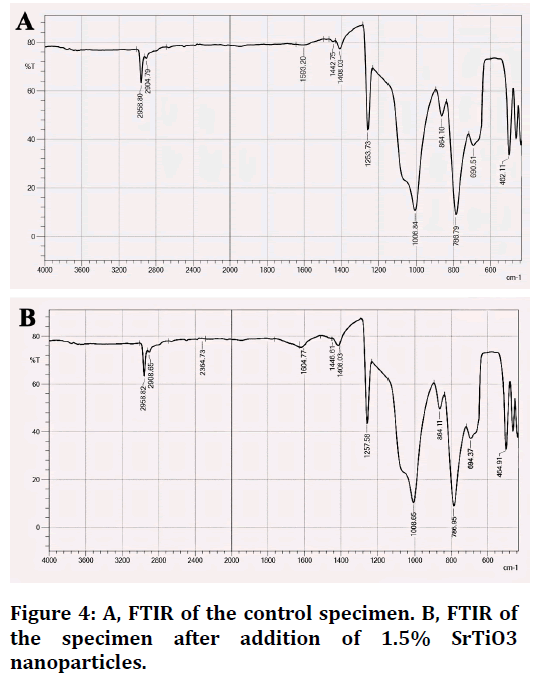

Fourier transform infra-red (FTIR)

FTIR device (SHIMADZU, Japan) was used to determine if there was a chemical interaction between silicone material and the strontium Titanate nanoparticles. Three specimens were tested, one from the group (A), group (B), and group (C).

The statistical analysis

The statistical analysis was done using one-way ANOVA (Analysis of variance) and post hoc tests (Tukey HSD) by statistical analysis software (IBM SPSS Statistics 26). Levene’s test was also conducted to determine the homogeneity of variances.

The probability (P) value of >0.05 was considered non-significant statistically (NS), P values of ≤ 0.05 were considered statistically significant (S), and P values of ≤ 0.01 were considered highly significant (HS).

Results

SEM Result: The SEM images showed well dispersion of SrTiO3 NPs inside the silicone matrix with some aggregation as the filler content increases as seen in (Figure 3A, B and C).

Figure 3. SEM images demonstrating uniform distribution of SrTiO3 nanoparticles with a number of large sized agglomerates as filler loading increases. (10 μm magnification) A: Control specimen. B: 1% SrTiO3 specimen. C: 1.5% SrTiO3 specimen.

FTIR Results: The test revealed no change on the spectra range of VST-50 silicone by the incorporation of SrTiO3 as presented in (Figure 4).

Figure 4. A, FTIR of the control specimen. B, FTIR of the specimen after addition of 1.5% SrTiO3 nanoparticles.

Mechanical Tests Results

Tensile strength

Groups (B and C) exhibited higher means than group (A). Tukey HSD test revealed highly significant difference between group (A) and groups (B and C), while a non-significant difference was found between group (B) and group (C) as seen in (Table 1).

| Tensile strength MPa | ANOVA | Tukey HSD | ||||||

|---|---|---|---|---|---|---|---|---|

| Group | Min | Max | Mean | ± SD | F | P value | Groups | P value |

| (A) | 4.05 | 4.38 | 4.192 | 0.033 | 100.742 | 0 | A B | 0.000 HS |

| (B) | 4.87 | 5.61 | 5.21 | 0.062 | A C | 0.000 HS | ||

| (C) | 4.69 | 5.4 | 5.144 | 0.067 | B C | 0.694 NS | ||

| Levene statistics=1.643, p value=0.212 [NS] | ||||||||

Table 1: Minimum values, maximum values, means, standard deviation, ANOVA (one way), and post-hoc test of tensile strength.

Elongation percentage

Both groups (B and C) exhibited a decrease in the elongation percentage values compared to group (A).

Tukey HSD revealed a highly significant difference between group (A) and groups (B and C). Also, between group (B) and (C) as shown in (Table 2).

| Elongation percentage% | ANOVA | Tukey HSD | ||||||

|---|---|---|---|---|---|---|---|---|

| Group | Min | Max | Mean | ±SD | F | P value | Groups | P value |

| (A) | 331.5 | 379.2 | 347.813 | 13.217 | 32.414 | 0 | A B | 0.000 HS |

| (B) | 318.4 | 335.5 | 326.008 | 5.878 | A C | 0.000 HS | ||

| (C) | 300.65 | 329.48 | 312.5611 | 9.14689 | B C | 0.014 HS | ||

| Levene statistics=1.243, p value=0.304 [NS] | ||||||||

Table 2: Minimum values, maximum values, means, standard deviation, ANOVA (one way), and post-hoc test of elongation percentage.

Tear strength

Both experimental groups (B and C) showed higher mean values than group (A). Tukey HSD results showed highly significant difference between the group (A) and groups (B and C). Also, highly significant difference between group (B) and group (C) was found (Table 3).

| Tear strength N/mm | ANOVA | Tukey HSD | ||||||

|---|---|---|---|---|---|---|---|---|

| Group | Min | Max | Mean | ±SD | F | P value | Groups | P value |

| (A) | 16.98 | 19.21 | 18.029 | 0.85906 | 151.568 | 0 | A B | 0.000 HS |

| (B) | 23.56 | 26.64 | 24.885 | 0.89992 | A C | 0.000 HS | ||

| (C) | 21.23 | 24.27 | 23.101 | 0.97796 | B C | 0.000 HS | ||

| Levene statistics=0.2174, p value=0.805 [NS] | ||||||||

Table 3: Minimum values, maximum values, means, standard deviation, ANOVA (one way), and post-hoc test of tear strength.

Hardness

The experimental groups (B and C) revealed higher means than group (A). Significant difference was found between the group (A) and group (B), while highly significant difference between group (A) and group (C). There was also a non-significant difference between group (B) and group (C) as seen in (Table 4).

| Shore A hardness | ANOVA | Tukey HSD | ||||||

|---|---|---|---|---|---|---|---|---|

| Group | Min | Max | Mean | ±SD | F | P value | Groups | P value |

| (A) | 28.7 | 33.8 | 31.51 | 1.4169 | 24.722 | 0 | A B | 0.05 S |

| (B) | 31.8 | 34 | 32.86 | 0.7427 | A C | 0.000 HS | ||

| (C) | 31.4 | 35.9 | 34.07 | 1.3679 | B C | 0.085 NS | ||

| Levene statistics=0.869, p value=0.430 [NS] | ||||||||

Table 4: Minimum values, maximum values, means, standard deviation, ANOVA (one way), and post-hoc test of hardness test.

Surface roughness

Group (C) revealed the highest mean followed by group (B). Group (A) had the lowest mean. Highly significant difference was found between group (A) and groups (B and C), while there was non-significant difference between group (B) and group (C) (Table 5).

| Roughness | ANOVA | Tukey HSD | ||||||

|---|---|---|---|---|---|---|---|---|

| Group | Min | Max | Mean | ±SD | F | P value | Groups | P value |

| (A) | 0.241 | 0.317 | 0.2888 | 0.044424 | 15.499 | 0 | A B | 0.008 HS |

| (B) | 0.261 | 0.384 | 0.3311 | 0.035597 | A C | 0.000 HS | ||

| (C) | 0.319 | 0.396 | 0.3598 | 0.023485 | B C | 0.082 NS | ||

| Levene statistics=1.017, p value=0.375 [NS] | ||||||||

Table 5: Minimum values, maximum values, means, standard deviation, ANOVA (one way), and post-hoc test of surface roughness.

Discussion

Silicone elastomers are widely used as a maxillofacial prosthetic material; however, their properties are far from ideal. This explains the continual rise in the number of studies to produce improved maxillofacial silicone materials, either by altering the composition or by reinforcing with various types of fillers in varying percentages [14]. The main objective of these researches was to improve the way of filler union with the polymer matrix to combine the beneficial properties of both materials at the same time [15].

Tensile strength is the inner force that prevents the elongation of the object in the same direction of force application. There was a highly significant increase in tensile strength for both experimental groups (1% and 1.5 % SrTiO3) when compared to the control group. This is explained by the fact that nanoparticles adsorb to polymer chains and create numerous crosslinking sites due to their high surface energy. As a result, the polymer's total crosslinking density increased, resulting in greater stiffness, which prevents the polymer chains from breaking [16]. Also, by the physical interconnection that occurred between SrTiO3 nanoparticles and VST-50 matrix. When the tensile forces applied, the nanoparticles and polymer chains start sliding over each other. Thus, preventing failure and breakage of the polymer chains [17].

Because nano fillers have a high surface energy, any increase in nano oxide concentration can lead to agglomeration. When silicone is subjected to forces, the agglomerated particles become the central point of stress concentration, resulting in quicker breakage of the silicone. This explains the non-significant reduction in tensile strength at 1.5% SrTiO3 when compared to 1% SrTiO3 [18].

Elongation is the ability of the material to stretch before failure after application of a tensile force. Percentage of elongation was significantly decreased for groups (1% and 1.5% SrTiO3) compared to the control group. The decrease in elongation percentage may be attributable to restrictions in flow and mobility of the polymer matrix as stretching forces increased, and since the areas of fillers serve as a tension concentration area, it will trigger breakage faster [19].

The decrease in elongation percentage may also be explained by a decrease in the gap between the filler’s aspect ratio and contents. As a result of the relatively short distance between rubber molecules, the elongation at fracture was reduced [20].

Tear strength which is the ability of the material to resist tearing forces that act at right angle to the surface flaw was increased for both experimental groups when compared to the control groups. From a physical point of view, nanoparticles can trap some polymer chains by the formation of three-dimensional networks inside the polymer matrix. This interaction between nanoparticles and polymer matrix can prevent movement of polymer chains against each other and against the nanoparticles. Consequently, increase in density and increase in tear strength occurs [21]. In addition, rubber materials can scatter the strain energy at the tip of the propagated crack. Nanoparticles, then can distribute their energy as the crack propagates and increase the material’s resistance to tearing [22]. When nano particle concentration is increased to 1.5%, a decrease in tear strength was observed. This decrease can be explained by the fact that as SrTiO3 nanoparticle concentration is increased, the filler begins to agglomerate, resulting in lower mechanical properties such as tear strength [18-23].

The hardness is the ability of the material to resist permanent surface indentation should be in the range of (10-45 IU) to be acceptable [24]. The increase in hardness values after addition of 1% and 1.5% of SrTiO3 can be caused by the spreading of the nanoparticles inside the polymer matrix and between the polymeric chains thus filling the inter-aggregate areas. This can increase the resistance to indentation and penetration making the material harder. As the concentration of SrTiO3 rises, so does the adsorption of the fillers to the polymer chain surface and the intermolecular forces increase. As a consequence, a stiff polymer with a high elastic modulus and improved deformation resistance is produced [25].

The increase in roughness values was highly significant. It can be explained by the fact that during preparation, nanoparticles start to agglomerate on the surface of the specimen as the filler content increases [26]. In addition, the difference in the microstructural properties of the silicone material and SrTiO3 nanoparticles might be the source of the increase in roughness.

Conclusion

The incorporation of SrTiO3 nanoparticles into VST-50 silicone in 1% and 1.5% weight percentages improved tear strength and tensile strength. However, there was significant decrease in percentage of elongation, while hardness and roughness increased but still within the acceptable range.

Conflict of Interest

All authors hereby certify that they have no conflicts of interest.

Source of Funding

The project is entirely self-funded.

Ethical Clearance

In-vitro study.

References

- Goiato MC, Pesqueira AA, Santos DMd, et al. Evaluation of hardness and surface roughness of two maxillofacial silicones following disinfection. Braz Oral Res 2009; 23:49-53.

- Aziz T, Waters M, Jagger R. Analysis of the properties of silicone rubber maxillofacial prosthetic materials. J Dent 2003; 31:67-74.

- Rahman A, Jamayet N, Nizami M, et al. Effect of Aging and weathering on the physical properties of maxillofacial silicone elastomers: A systematic review and meta-analysis. J Prosthet 2018; 28:36-48.

- Guiotti A, Goiato M, dos Santos D. Marginal deterioration of the silicone for facial prosthesis with pigments after effect of storage period and chemical disinfection. J Craniofac Surg 2010; 21:142-145.

- Wang L, Liu Q, Jing D, et al. Biomechanical properties of nano-TiO2 addition to a medical silicone elastomer: The effect of artificial ageing. J Dent 2014; 42:475-483.

- Hayashi S, Fujiki K, Tsubokawa N. Grafting of hyperbranched polymers onto ultrafine silica: Post graft polymerization of vinyl monomers initiated by pendant initiating groups of polymer chains grafted onto the surface. React Funct Polym 2000; 46:193-201.

- Han Y, Kiat-amnuay S, Powers J, et al. Effect of nano-oxide concentration on the mechanical properties of a maxillofacial silicone elastomer. J Prosthet Dent 2008; 100:465-473.

- Tariverdian T, Behnamghader A, Brouki Milan P, et al. 3D-printed barium strontium titanate-based piezoelectric scaffolds for bone tissue engineering. Ceram Int 2019; 45:14029-14038.

- Fatihallah A, Alsamaraay M. Effect of Polyamide (Nylon 6) Micro-Particles Incorporation into RTV maxillofacial silicone elastomer on tear and tensile strength. J Bagh Coll Dent 2017; 29:7-12.

- www.iso.org/standard/ 70323.html

- www.iso.org/standard/68116.html

- www.iso.org/standard/65926.html

- www.iso.org/standard/50756.html

- Zayed S, Alshimy A, Fahmy A. Effect of surface treated silicon dioxide nanoparticles on some mechanical properties of maxillofacial silicone elastomer. Int J Biomater 2014; 2014:1-7.

- Kantola R, Lassila L, Tolvanen M, et al. Color stability of thermochromic pigment in maxillofacial silicone. J Adv Prosthodont 2013; 5:75.

- Andreopoulos A, Evangelatou M. Evaluation of various reinforcements for maxillofacial silicone elastomers. J Biomater Appl 1994; 8:344-360.

- Zhu A, Sternstein S. Nonlinear viscoelasticity of nanofilled polymers: interfaces, chain statistics and properties recovery kinetics. Compos Sci Technol 2003; 63:1113-1126.

- Han Y, Kiat-amnuay S, Powers JM, et al. Effect of nano-oxide concentration on the mechanical properties of a maxillofacial silicone elastomer. J Prosthet Dent 2008; 100:465-73.

- Rajkumar K, Ranjan P, Thavamani P, et al. Dispersion studies of nanosilica in nbr based polymer nanocomposite. Rasayan J Chem 2013; 6:122-33.

- Ryu S, Lee D. Effects of fiber aspect ratio, fiber content, and bonding agent on tensile and tear properties of short-fiber reinforced rubber. KSME Int J 2001; 15:35-43.

- Varatharajan S, Krishnaraj R, Sakthivel M, et al. Design and analysis of single disc machine top and bottom cover. Int J Sci Eng Res 2011; 2:16.

- Sun L, Gibson R, Gordaninejad F, et al. Energy absorption capability of nanocomposites: A review. Compos Sci Technol 2009; 69:2392-2409.

- Zayed SM, Alshimy AM, Fahmy AE. Effect of surface treated silicon dioxide nanoparticles on some mechanical properties of maxillofacial silicone elastomer. Int J Biomater 2014; 2014:1-7.

- Eleni P, Krokida M, Polyzois G, et al. Effect of different disinfecting procedures on the hardness and color stability of two maxillofacial elastomers over time. J Appl Oral Sci 2013; 21:278-283.

- Hasse A, Wehmeier A, Luginsland HD. Crosslinking and reinforcement of silica/silane-filled rubber compounds 2004; 22-31.

- Alnamel H, Mudhaffer M. The effect of silicon di oxide nano-fillers reinforcement on some properties of heat cure polymethyl methacrylate denture base material. J Bagh Coll Dent 2014; 26:32-36.

Author Info

Ali Saad Ahmed* and Mohammed Moudhaffer Mohammed Ali

Department of Prosthodontics, College of Dentistry, University of Baghdad, IraqCitation: Ali Saad Ahmed, Mohammed Moudhaffer Mohammed Ali, Effect of Strontium Titanate Nano Powder Addition on Some Mechanical Properties of Room Temperature Vulcanized Maxillofacial Silicone, J Res Med Dent Sci, 2021, 9(12): 59-65

Received: 30-Oct-2021 Accepted: 23-Nov-2021