Research - (2021) Volume 9, Issue 2

Evaluation of the Effect of Various Surface Treatment Methods on Shear Bond Strength between Zirconia Post and Composite Resin Core Material: An In-Vitro Study

Manu Verma1*, Anumeha Jha1, Manisha Minz1, Jenifer Kerketta1, Brajendra Dubey2 and Mahendra Anant1

*Correspondence: Manu Verma, Department of Prosthodontics, Government Dental College Raipur Chhattisgarh, India, Email:

Abstract

Introduction: In the prosthetic rehabilitation of the maxillary anterior region, zirconia restorations are frequently used. Aim: To evaluate the shear bond strength between zirconia post and composite resin core material with different surface treatment. Material and Methods: Total 80 samples of sintered zirconia blocks (5mm X 5mm X 2mm) were fabricated for this study. These zirconia blocks were fixed on acrylic block and four different groups were made on basis of surface treatment. Group 1 (G1) no surface treatment, Group II (G2): Laser etching with Er: YAG laser, Group III (G3): Internal coating (INT) with silica based porcelain, Group IV (G4): Aluminium nitride nano particles. After surface treatment, zirconia primer was applied over surface treated zirconia specimen. Composite resin blocks were fabricated with help of glass mold measuring 5mm X 5mm X 2mm and luted with same composite material over zirconia block. Shear bond strength was measured by universal testing machine at across head speed of 1mm per minute. Surface of each specimen was observed under Stereomicroscope and two specimen of each test group were evaluated under Scanning electron microscope. Data was analyzed using Tukey Test and Dunnett D Test. Results: The mean shear bond strength obtained was 1.62 MPa with control group, 2.99 MPa, 2.80 MPa and 4.91 MPa with laser group, internal coating group and Aluminium nitride group respectively. Conclusion: All the surface treatment methods in the study enhanced the shear bond strength between zirconia and composite resin when compared with the control group. Surface treatment with Aluminium nitride nano particle showed highest mean shear bond strength.

Keywords

Aluminium nitride, Internal coating, Laser, Zirconia

Introduction

In the prosthetic rehabilitation of the maxillary anterior region, all-ceramic and zirconia restorations are frequently used. When a ceramic crown is cemented to the tooth with translucent cement, the darker shade of the root may be visible through the cervical portion of the crown. This phenomenon can be more pronounced when metallic dowels are used because they may produce a gray discoloration of translucent allceramic crowns and the surrounding gingiva [1]. These problems, as well as the growing demand for esthetic restorations in dentistry, have led to the development of tooth-colored, metal free dowel and core systems like fiber reinforced composite resin and zirconia based ceramics.

Zirconia posts are composed of zirconium dioxide (ZrO2), partially stabilized with 3% to 6% yttrium oxide (Y2O3) and exhibit a polymorphic structure with monoclinic, tetragonal and cubic crystalline phases [2]. Zirconia posts can be used with an indirect technique, in which a glass ceramic core material is directly heat-pressed onto the zirconia post [3]. Alternative treatment options include heat pressing the glass ceramic core separately and then luting it to the post with a resin luting agent or direct application of a composite resin core material [4]. Although an improvement in fracture resistance was obtained with both of these techniques, composite resin core materials provide additional clinical benefits because of their ability to bond to the tooth structure in association with bonding agents and because they allow immediate tooth preparation. The durability of a composite resin core restoration depends on the formation of a strong bond between the core material and the residual dentin, as well as between the core and post material, enabling the interface to transfer stresses under functional loading [5,6]. Compared to prefabricated metal posts, lower bond strengths were reported for bonding of zirconia posts to composite resin core materials [7]. This result was related to the smooth surface of zirconia posts, which prevent any macro mechanical and micromechanical retention to the composite resin core materials [7]. For this reason, zirconia posts were more susceptible to adhesive failure at the zirconia post and composite resin interface [1]. Dérand et al. concluded in their study that washing with hydrofluoric acid had no significant influence on bond strength between resin and zirconia ceramic [8]. To enhance the bond strength of composite resins to the ceramic surface, different surface treatments have been proposed by different authors i.e. application of tribochemical silica coating, chloro-silane treatment, selective infiltration etching, nanostructure Aluminium coating, hot chemical etching solution, laser application, internal coating with silica based ceramic etc. [9].

Nanostructure Aluminium coating, laser application, internal coating with silica based ceramic etc. are newer techniques which enhance the bond strength between zirconia core and composite resin core materials. Previous studies have advocated about the effectiveness of individual surface treatment techniques but controversies still exist regarding better technique amongst them. Keeping in mind the above mentioned factors, this study was planned to evaluate and compare the shear bond strength between the zirconia and composite resin material with three latest surface treatment techniques.

Material and Methods

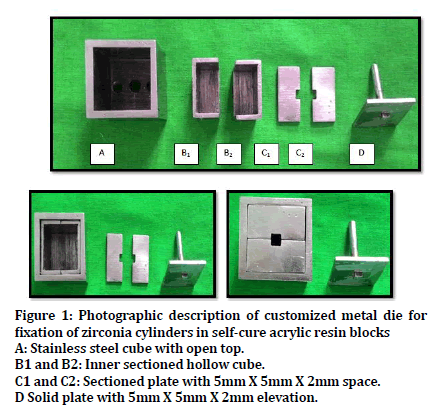

In this experimental in-vitro study 80 sintered zirconia blocks (Shenzhen opera dental technology Guangdong) of 5 mm X 5 mm X 2 mm dimension were made with help of CAD/CAM (CAM 4K-3 Impression, Palladium Dent, Jordan) from non-sintered zirconia blank. These zirconia blocks were fixed on self-cure acrylic resin block of 25 mm X 25 mm X 25 mm. Acrylic resin blocks were made with help of customized metal die for Standardized placement of zirconia block on acrylic blocks (Figure 1).

Figure 1. Photographic description of customized metal die for fixation of zirconia cylinders in self-cure acrylic resin blocks

A: Stainless steel cube with open top.

B1 and B2: Inner sectioned hollow cube.

C1 and C2: Sectioned plate with 5mm X 5mm X 2mm space.

D Solid plate with 5mm X 5mm X 2mm elevation.

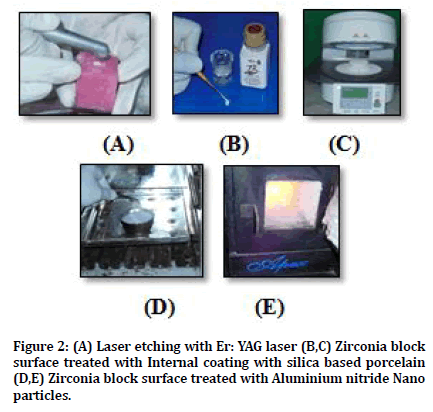

All specimens were ground with 400 grit silicon carbide paper and ultrasonically cleaned in distilled water for 10 minutes to remove contamination before surface treatment. 80 samples were divided in four equal groups. In group I and Group II surface treatment was done after fixation of zirconia block into acrylic resin block but in Group III and Group IV surface treatment was done before fixation of zirconia block into acrylic resin block. Specimens in group I(G1:- No surface treatment, control group) were ground only with 400 grit silicon carbide paper no other surface treatment were done. Specimens of group II (G2:- Laser etching with Er: YAG laser) were subjected to Er: YAG laser irradiation with 40 Hz pulsed laser powered hydrokinetics and energy parameter of 2.5 W (Figure 2A). The air and vapor were adjusted to 45% of laser unit. The optical fiber of laser was aligned perpendicular to each specimen at a distance of 2 mm and moved manually in sweeping fashion over the entire area during 60 seconds exposure time. Specimens of group III (G3-Internal coating (INT) with silica based porcelain). The sintered zirconia block were air abraded with 110 μm Al2O3 at 0.5 MPa for 5 seconds and then coated with a medium fusing porcelain (Vintaze ZR, shade A2B ,Shofu, Japan) which is ceramic veneering material designed exclusively for use with the zirconia framework. The porcelain powder was stirred in excessive amount of distilled water and immediately painted on the zirconia block surface and fired at 925˚C for 1 minute with the vacuum to make a coating of micro thickness (Figure 2B and 2C). For group IV [G4-Aluminium nitride Nanoparticles (ALN)] sintered zirconia block of specific dimension were air abraded with 110 μm Al2O3 at 0.5 MPa for 5 seconds. The Aluminium nitride powder for the adhesive coating was Aluminium Nitride (PL-HK-Aluminium Nitride, Plasmachem, Berlin) with median particle size of 20 nm, a surface area of 80±7 m2/g and purity was > 99%. A diluted aqueous suspension containing 3 wt% of Aluminium Nitride powder was prepared by dispersing 3 g of Aluminium Nitride powder in 100 ml of deionized water, preheated to 75°C. Immediately after dispersing the Aluminium Nitride powder, as-sintered and air-particle abraded Y-TZP substrates were immersed in the suspension for 15 min. Once exposed to hot water, the dispersed Aluminium Nitride powder starts decomposing resulting in the formation of a Nano-structured boehmite coating onto the surface of immersed substrates. The coated substrates were subsequently airdried in an oven for 2 h at 110°C, and thermally treated by heating in an electric resistance furnace in atmospheric air at 900°C for 1 h. The heating rate was 10°C/min (Figure 2D, 2E). Following surface treatment the specimens of each group were ultrasonically cleaned in distilled water for 10 minutes and air dried. A composite resin block was made with specific dimension 5 mm X 5 mm X 2 mm with the help of glass mold. After surface treatment, ultrasonic cleaning and air drying of specimens the zirconia primer (Monobond plus, ivoclar vivadent) was applied over the zirconia block with the help of applicator brush and allowed to react for 60 seconds. Then small amount of composite resin core build-up material (Multicore Flow, Ivoclar Vivadent) was applied over the zirconia block and just after that composite resin block was pushed over it. Curing was done with light curing device (Dent Arc). After luting of composite block over zirconia specimens were kept in distilled water for 24 hours at 37˚C temperature.

Figure 2. (A) Laser etching with Er: YAG laser (B,C) Zirconia block surface treated with Internal coating with silica based porcelain (D,E) Zirconia block surface treated with Aluminium nitride Nano particles.

Each specimen is subjected to shearing forces until bond failure using a Universal testing machine (ACME Engineers, India. Model No. UNITEST-10) with across head speed of 1mm per minute. To observe morphological changes of different surface treatment on zirconia surface, two samples from each group were observed under Scanning Electron Microscope (SEM). The shear bond tested samples were observed under Stereomicroscope to observe the mode of bond failure (Table 1).

| Group | N | Mean | Std. Deviation | Std. Error | 95% Confidence Interval for Mean | Minimum | Maximum | |

|---|---|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||||

| Control | 20 | 1.62 | 0.26 | 0.05 | 1.5 | 1.75 | 1.17 | 2.03 |

| INT | 20 | 2.8 | 0.69 | 0.15 | 2.48 | 3.12 | 1.55 | 4.51 |

| Laser | 20 | 2.99 | 0.65 | 0.14 | 2.68 | 3.29 | 1.98 | 4.08 |

| ALN | 20 | 4.91 | 1.47 | 0.32 | 4.22 | 5.59 | 3.21 | 7.7 |

Table 1: Mean values and standard deviation for all groups’ descriptive statistics.

Results

The mean shear bond strength obtained was 1.62 MPa with control group, 2.99 MPa, 2.80 MPa and 4.91 MPa with laser group, internal coating group and Aluminium nitride group respectively (Graph 1).

As seen in table 2 (ANOVA test) it is seen that shear bond strength was significantly affected by the surface treatment methods. As ANOVA test showed significant results (P ≤ 0.001) further multiple comparison test (Tukey’s test) was done which depicted that statistically significant difference was found between group III (internal coating, INT) and group IV (Aluminium nitride Nano-particle, ALN) and between group II (Laser) and group IV (ALN) and no significant difference found between group III (INT) and group IV (Laser) (Table 3).

| Source of variation | Sum of Squares | Df | Mean Square | F | p-value |

|---|---|---|---|---|---|

| Between Groups | 110.99 | 3 | 36.99 | 47.093 | 0.0001, S,p<0.05 |

| Within Groups | 59.71 | 76 | 0.78 | ||

| Total | 170.7 | 79 |

Table 2: One way ANOVA.

| Group | Mean Difference (I-J) | Std. Error | p-value | 95% Confidence Interval | ||

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| INT | Laser | -0.18 | 0.28 | 0.911,NS,p>0.05 | -0.92 | 0.55 |

| ALN | -2.1 | 0.28 | 0.0001,S,p<0.05 | -2.84 | -1.36 | |

| Laser | ALN | -1.92* | 0.28 | 0.0001,S,p<0.05 | -2.65 | -1.18 |

Table 3: Multiple comparison: Tukey test.

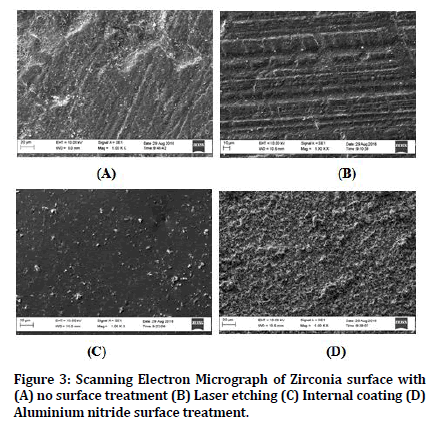

Scanning electron microscopic evaluation of surface treated zirconia revealed morphological changes, Group I (control) showed some irregularities and scratches, Group II (Laser) increased scratches and rough surface, Group III (INT) showed smooth surface with some elevations and Group IV (ALN) showed large micro retentive areas (Figure 3). In type of bond failure analysis all groups showed adhesive failure between zirconia and composite (A) and mixed adhesive and cohesive types (M) of bond failure with no cohesive bond failure between composite resin only (C-C) or zirconia only (C-Z).

Figure 3. Scanning Electron Micrograph of Zirconia surface with (A) no surface treatment (B) Laser etching (C) Internal coating (D) Aluminium nitride surface treatment.

Discussion

The results obtained from present study demonstrated that the application of MDP containing primer/silane mixture to the surface treated zirconia surface (laser etching, internal coating, aluminium nitride nano particle) provide higher shear bond strength as compared to application of MDP containing primer to the zirconia surface without any surface treatment (control group). Therefore the results support rejection of hypothesis that there is no difference in shear bond strength. The surface treatment evaluated in the study included mechanical and chemical bonding procedure. MDP containing primer provide chemical bonding between zirconia oxide and MDP. The phosphate ester monomer of the MDP was reported to bond directly to metal oxide such as aluminium and zirconium oxide and have resin terminal end that bond to the resin cement. 2 MDP is a relatively hydrophobic monomer due to its 10– carbon chain and contain both a hydrophilic phosphate terminal end that chemically adhere to the zirconia and polymerizable methacrylate terminal end that adhere to the resin [10]. Oyague et al observed phosphate monomer containing luting system significantly increase the bond strength between zirconia oxide ceramic and composite. Bond strength of MDP containing cement to zirconia was significantly higher than other cements, regardless of the surface treatment [11].

With the INT (Internal) coating technique, the internal surface of the zirconia restoration is partially or fully covered with silica based ceramics by fusion to the zirconia surface at 925˚C. In the laboratory, a zirconia frame with a large marginal or internal gap can be repaired with silica-based ceramics using the INT coating technique [12]. Kitayama et al. concluded in their study that with salinization, the internal coating were effective in improving bond strength if resin cement to zirconia ceramics [13].

Nanostructured alumina coating is presented as a new approach which is able to provide a strong and durable resin bond to Y-TZP. It is based on the idea of a rapid precipitation of Aluminium hydroxides that originate from the hydrolysis of Aluminium nitride (AlN) powder in a diluted aqueous suspension. The result is heterogeneous nucleation of lamellar boehmite (γAlOOH) onto the surface of the immersed Y-TZP substrate. The nanostructured coatings consist of 6 nm thick and 240 nm long interconnected polycrystalline γAlOOH lamellas that grow perpendicular to the zirconia surface. During a heat treatment up to 900°C, these coatings are transformed into transient alumina, but without any change in the morphology [14,15]. This is a non-invasive method to increase the surface area. Jevnikar et al. concluded in their study that the application of an alumina coating to YTZP ceramics created a highly retentive surface for resin penetration. The coating showed good surface coverage and a uniform thickness of 240 nm [14].

Study conducted by Kasraei et al. showed similar results and they observed that 2W Er:YAG lasers resulted in a significant higher shear bond strength of resin cement to zirconia ceramics. Surface pretreatment by Er:YAG laser enhanced surface roughness with a scaly appearance. The energy density of the laser beam was higher considering the diameter of the laser beam delivered, which resulted in a rough surface due to its thermal effects and increased in bond strength between zirconia and resin was seen [16].

In the present study it was seen after scanning electron microscopy (SEM) that without any surface treatment there was some irregularities and after laser surface treatment there was increase in irregularities and roughness. For INT coating a smooth surface was observed with some elevations. With Aluminium nitride Nano particle (ALN) surface treatment rough and large micro-retentive areas was seen. Zhu et al. found smooth surface under scanning electron microscope after internal coating with silica based ceramic since surface was not air abraded [12]. Jevnikar et al. observed that the application of an alumina coating to YTZP ceramics created a highly retentive surface for resin penetration. The coating showed good surface coverage and a uniform thickness of 240 nm. No cracks and delamination were observed [14]. Arami et al. found under SEM analysis that Er: YAG laser with power of 1.5W created a rough surface with irregularities. Surface roughness increased by enhancing output power to 2W; also, the surface became more uniform. Treated surfaces by CO2 laser with power of 3W showed several fine and wide crack lines. Nd: YAG laser at a power of 1.5W created surface microcracks, prominences and porosities; moreover, some areas were partially melted [17].

Shear bond tested all specimens were analyzed for types of bond failure on the basis of surface topography with the help of stereomicroscope. Out of adhesive, cohesive and mixed bond failure, adhesive failure and mixed failure were observed. In other studies it was seen that combination of adhesive and mixed failure was present [18-20]. It should be noted that bond strength between the zirconia and composite resin depends on chemical reaction as well as mechanical bonding, some studies has been done for bond strength with different types of primers and bonding systems [21,22]. Still further studies are required to assess the effect of different primer and bonding system containing different chemical compositions. Different type of laser in combination with different type of surface treatment can be used to assess and compare the effectiveness of these methods. The result of present study should be considered with several experimental limitations.

The present study was done in in-vitro condition the effect of same surface treatment and materials can be slight different in oral environment. Moreover the size and shape of zirconia and composite blocks used in the study does not mimic the size and shape of zirconia post and also the shape of teeth. Further studies could be done in clinical condition to verify the outcome of present study in clinical situation.

Conclusion

Within the scope and limitation of the study following conclusion were drawn after critically evaluating the results based on statistical analysis:-

✓ All the surface treatment methods in the study enhanced the shear bond strength between zirconia and composite resin when compared with the control group (Without surface treatment).

✓ Surface treatment with Aluminium nitride Nano particle showed highest mean shear bond strength between zirconia and composite resin core material, followed by surface treatment with Laser, surface treatment with Internal coating and without surface treatment.

✓ Surface treatment with Aluminium nitride Nano particle showed statistically highest values of shear bond strength when compared to the other three groups. Surface treatment with Laser and with Internal coating showed more or less similar values of shear bond strength.

✓ Scanning electron microscope (SEM) analysis showed that surface treatment of zirconia with Aluminium nitride nano particles create large micro-retentive areas and appear to be more retentive.

✓ Failure analysis with stereomicroscope showed that least number of adhesive bond failure were showed by Aluminium nitride nano particle surface treatment.

References

- Al-harbi F, Nathanson D. In vitro assessment of retention of four esthetic dowels to resin core foundation and teeth. J Prosthet Dent 2003; 90:547-555.

- Akgungor G, Sen D, Aydin M. Influence of different surface treatments on the short-term bond strength and durability between a zirconia post and a composite resin core material. J Prosthet Dent 2008; 99:388-399.

- Heydecke G, Butz F, Hussein A, et al. Fracture strength after dynamic loading of endodontically treated teeth restored with different post-and-core systems. J Prosthet Dent 2002; 87:438-445.

- Edelhoff D, Sorensen JA. Retention of selected core materials to zirconia posts. Oper Dent 2002; 27:455-461.

- O'Keefe KL, Powers JM. Adhesion of resin composite core materials to dentin. Int J Prosthodont 2001; 14:451-456.

- Aksornmuang J, Foxton RM, Nakajima M, et al. Microtensile bond strength of a dual-cure resin core material to glass and quartz fibre posts. J Dent 2004; 32:443-450.

- Cohen BI, Pagnillo MK, Newman I, et al. Retention of a core material supported by three post head designs. J Prosthet Dent 2000; 83:624-628.

- Dérand P, Dérand T. Bond strength of luting cements to zirconium oxide ceramics. Int J Prosthodont 2000; 13:131-135.

- Obradović-Djuričić K, Medić V, Dodić S, et al. Dilemmas in zirconia bonding: A review. Srp Arh Celok Lek 2013; 395-401.

- Griffin J, Suh B, Chen L, et al. Surface treatments for zirconia bonding: a clinical perspective. Canadian J Restorative Dent Prosthodont 2010; 3:23-29.

- Oyagüe RC, Monticelli F, Toledano M, et al. Influence of surface treatments and resin cement selection on bonding to densely-sintered zirconium-oxide ceramic. Dent Mater 2009; 25:172-179.

- Zhu L, Nikaido T, Kitayama S, et al. Effect of surface abrasion and silica coating on tensile bond strength of a resin cement to zirconia ceramics. Int Chin J Dent 2009; 9:23-30.

- Kitayama S, Nikaido T, Maruoka R, et al. Effect of an internal coating technique on tensile bond strengths of resin cements to zirconia ceramics. Dent Mater J 2009; 28:446-453.

- Jevnikar P, Krnel K, Kocjan A, et al. The effect of nano-structured alumina coating on resin-bond strength to zirconia ceramics. Dent Mater 2010; 26:688-696.

- Külünk T, Külünk S, Baba S, et al. The effect of alumina and aluminium nitride coating by reactive magnetron sputtering on the resin bond strength to zirconia core. J Adv Prosthodont 2013; 5:382-387.

- Kasraei S, Atefat M, Beheshti M, et al. Effect of surface treatment with carbon dioxide (CO2) laser on bond strength between cement resin and zirconia. Lasers Med Sci 2014; 5:115-120.

- Amaral R, Özcan M, Bottino MA, et al. Microtensile bond strength of a resin cement to glass infiltrated zirconia-reinforced ceramic: The effect of surface conditioning. Dent Mater 2006; 22:283-290.

- Blatz MB, Sadan A, Martin J, et al. In vitro evaluation of shear bond strengths of resin to densely-sintered high-purity zirconium-oxide ceramic after long-term storage and thermal cycling. J Prosthet Dent 2004; 91:356-362.

- Jedynakiewicz NM, Martin N. The effect of surface coating on the bond strength of machinable ceramics. Biomaterials 2001; 22:749-752.

- Kasraei S, Rezaei-Soufi L, Heidari B, et al. Bond strength of resin cement to CO2 and Er: YAG laser-treated zirconia ceramic. Restor Dent Endod 2014; 39:296-302.

- Aboushelib MN, Matinlinna JP, Salameh Z, et al. Innovations in bonding to zirconia-based materials: Part I. Dent Mater 2008; 24:1268-1272.

- Chen L, Shen H, Suh BI. Effect of incorporating BisGMA resin on the bonding properties of silane and zirconia primers. J Prosthet Dent 2013; 110:402-407.

Author Info

Manu Verma1*, Anumeha Jha1, Manisha Minz1, Jenifer Kerketta1, Brajendra Dubey2 and Mahendra Anant1

1Department of Prosthodontics, Government Dental College Raipur Chhattisgarh, India2Vananchal Dental College and Hospital Garwa Jharkhand, India

Citation: P Harini, R Gayathri, V Vishnu Priya, Antioxidant and Antihypercholesterolemic Potential of Crude Aqueous Leaf Extract of Annona Muricata: An in vitro Study, J Res Med Dent Sci, 2021, 9 (2): 358-363.

Received: 12-Nov-2020 Accepted: 08-Feb-2021