Research - (2023) Volume 11, Issue 5

Mechanical Evaluation of Hybrid Ceramic compared with Zirconia as an implant abutment material

Ehab Bassam Al-sharifee* and Ahmed Asim Saeed Al-Ali

*Correspondence: Ehab Bassam Al-sharifee, Department of Prosthodontics, College of dentistry University of Mosul, Mosul, Iraq, Email:

Abstract

Aim: The aims of this in-vitro study are to evaluate and compare the different mechanical properties (microhardness, flexural strength and flexural modulus) of hybrid ceramics Cerasmart & Vita Enamic) with Y-TZP zirconia (as a prosthetic dental material. Materials and Methods: The total of 40 samples (microbars) has been prepared and tested; 20 samples of hybrid ceramics (10 of Cerasmart hybrid ceramic type from GC group, America & 10 of Vita Enamic hybrid ceramic type from Vita, Germany). 5 microbars of each type of hybrid ceramic (Cerasmart &Vita Enamic) of dimensions (1.5 *20*1 mm) have been prepared for flexural strength & flexural modulus test according to (ISO specification 6872-2015) (n=5), 5 microbars of each type of hybrid ceramic (Cerasmart &Vita Enamic) of dimensions (5*25*1.5 mm) were cut for micro-hardness according to (ISO specification 6872-2015) (n=5). 20 samples of 3Y-TZP Zirconia from Zircon Zahn, Germany has been prepared. 10 microbars of 3Y-TZP zirconia of dimensions (1.5 *20*1 mm) prepared for Flexural strength & Flexural modulus test according to (ISO specification 6872-2015), 10 microbars of 3Y-TZP zirconia of dimensions (5*25*1.5 mm) were cut for micro-hardness test according to (ISO specification 6872-2015) (n=10). Results: Zirconia has higher mechanical properties in term of hardness, flexural strength and flexural modulus than two hybrid ceramics. Cerasmart hybrid ceramics has higher hardness & flexural strength values than Vita Enamic. Cerasmart hybrid ceramics has equal value of flexural modulus with Vita Enamic. Cerasmart hybrid ceramics has high values of flexural strength than Vita Enamic Conclusion: Zirconia has better mechanical properties in term of hardness and flexural strength than two hybrid ceramics. Hybrid ceramics has higher elasticity than traditional zirconia since these materials has unique structure the acrylate polymer network ensures flexibility. Hybrid ceramics especially Cerasmart is good indication for fixed prosthesis and implant abutment.

Keywords

Hybrid ceramic

Introduction

Teeth loss is one of the most prevalent oral health issues for our patients. There are a various forms for rehabilitation of edentulous or partially edentulous patients such as implant-supported fixed prosthesis, the materials used in dental restorations & dental prosthesis must possess sufficient biocompatibility, aesthetics and mechanical properties Metal alloy crowns have long been considered the gold standard for tooth replacement. However, metal alloys, have some limitations the most important one is aesthetic limitations [1]. Zirconia containing ceramic restorations was used as the standard in aesthetic dentistry due to their high esthetics & teeth like colors, high biocompatibility and good mechanical properties [2]. Nowadays the most commonly used restorations are based on zirconium oxide due to its high aesthetics and high strength that is reaching approximately (2000) MPa [3]. The mechanical properties of all ceramics (zirconia containing ceramics) depend on the mole percent concentration of yttrium. The 3-moll % of yttria-tetragonal zirconia polycrystals (3-YTZP zirconia) has the finest mechanical possessions due to its tall tetragonal grain gratified resulting in transformation durability that inhibits crack development. Ceramic and composite are some of the materials that can be used to complete restorations. Ceramic have an excellent mechanical and optical property as well as biocompatibility, On the other hand, composite are easy to handle and repair, are more flexible and less abrasive to antagonists, but are less wear-resistant, making it difficult to achieve a good polish that it is a disadvantage compared to ceramics [4]. Ceramic and resin composite CAD/CAM milling blocks have been tested & prepared for high-quality, digitally tailored restorations that called resin ceramic blocks (RCB) (5). Although CAD/CAM ceramic blocks are still being used more clinically, recently there has been an increase in interest in resin composite blocks (RCB) due to their useful & unique properties [5].When searching for an ideal restorative material, some authors suggest linking the dentin-like elastic modulus of composites and all enamel-like ceramics to aesthetic properties [6]. For this purpose, dental materials have been developed that mimic the mechanical and optical properties of natural teeth called hybrid ceramics. This hybrid ceramics have a hybrid unique structure that reduces the material's brittleness and surface hardness, allowing for easier milling in a shorter time and promising better clinical outcomes. The hybrid ceramics have the positive properties of composites and ceramics, reducing the wear of the corresponding dental arches [7].

Tests of the samples

The tests of the samples that will be done are Hardness test by Vickers Microhardness device. Flexure strength by Universal testing machine. Flexural modulus by Universal testing machine.

Hardness property of dental materials

It is the ability of a material to resist deformation caused by surface penetration or strengthening. Example of hardness: The surface hardness of ceramics is therefore high; they can wear away opposing natural or artificial teeth [8].

Vickers microhardness test

The Vickers hardness indenter is a square diamond, which leaves a square diamond indentation on the surface of the tested material. Microhardness is determined by measuring the diagonal of a square and taking the average of the two dimensions. The Vickers hardness test is used to measure the microhardness of dental materials and alloys. This test is suitable for brittle materials and is therefore used to measure the hardness of the tooth structure. The thickness of the disc allows for the penetration depth of the sample not to be compromised during the Vickers hardness test, since the minimum thickness of the sample must be at least (10 times) the expected penetration depth [9].

Flexural Strength of dental materials

The flexural strength of a physical is a bodily property that couriers the ability of the physical to bend. Instinctively, it is the ratio of stress to straining during winding deformation or bending. The flexural strength or bending stress of materials are an important criterion for the selection of restorative materials in permanent prostheses, especially when they involve posterior regions, since their fracture resistance is directly related to long-term effectiveness. There is no global standard for assessing bending stress at fracture of tooth structures. Therefore, a 3-point bending test was performed according to the method used by other authors to simulate real conditions [10]. The advantage of the 3-point bend test is that it tends to reproduce the expected loading conditions in the oral cavity. Indeed, both anatomy and the neuromuscular system determine the mechanics of chewing devices and, ultimately, the manner in which forces are transmitted to tooth structures and/or restorative materials. Therefore, there is rarely a simple axial load, but a combination of compressive, shear and tensile forces [11].

Flexural modulus of dental materials

Elastic modulus or flexural modulus is a key property controlled by the microstructure of a material and the interatomic bonds between its constituents. More specifically, it is a measure of a material's ability to resist elastic deformation; the elastic modulus represented by the ratio of elastic stress to elastic strain by the slope of the straight-line portion of the stress-strain curve. The modulus of elasticity is also a constant, so it is not affected by the accumulated stress (elastic or plastic) in the material. As mentioned earlier, there are several tests that can be used to measure the modulus of elasticity, but the bend test is the most commonly used, mainly for convenience.

Materials and Methods

Materials

The tests materials and it is manufacturers used in the study are listed in table 2.1.

| No. | Item | Trade name | Manufacturer | Country of origin |

|---|---|---|---|---|

| 1 | Hybrid ceramic blocks | CERASMART | GC | USA |

| 2 | Hybrid ceramic blocks | VITA ENAMIC | VITA | Germany |

| 3 | zirconia disks | 3Y-TZP | Zircon Zahn | Italy |

Table 2.1Materials used in the study.

Methods

Samples preparation

40 samples were prepared for testing (microhardness, flexural strength and flexural modulus) according to the International Specification (ISO). Hybrid ceramics (Cerasmart and Vita Enamic), zirconia (3Y-TZP zirconia) micro rods (microbars) have been fabricated using a precision cutter and low-speed micro-motors under water cooled conditions and used to evaluate the mechanical properties of the three materials. The samples were divided into two group according to the materials used in this study, as follows:

The first group: The total of 20 hybrid ceramic samples (10 of Cerasmart type and 10 of Vita Enamic type) 10 samples used for microhardness test (5 from Cerasmart & 5 from Vita Enamic), for flexural strength and flexural modulus test also 10 samples has been tested.

The second group: 20 total zirconia samples has been prepared, 10 for microhardness test and 10 for flexural strength & flexural modulus test.

Tests of the samples Vickers micro hardness test

Take 10 samples from each group and use a Vickers hardness tester (Digital Micro-Hardness Tester/LARYEE) to measure the hardness value. The diamond indenter used is a square-bottomed regular pyramid with a middle angle of 136 degrees. The opposite face of a bears the load (1 kg for zirconia, 500 g for hybrid ceramic). Apply full load for 15 seconds. The two diagonals of the indentation after removal of the load are measured with an optical microscope and their average value is calculated. Calculate the area of the slope of the cavity.

The Vickers hardness was calculated by dividing the load by the square area of indentation: (HV = F/d^2).

HV = The Vickers hardness value. F = Load in kg. d^2 = Arithmetic mean of the two diagonal in mm.

Flexural strength and Flexural modulus test

Each sample was connected to the lower compartment of a universal testing machine (GT-7001-LCU computerized universal testing machine, GOTECH Testing Machines INC., Taiwan), in addition, a static load was compressively applied to the central of the sample surface and its tip is fixed to the upper mobile compartment of the testing machine. Loading was performed at a crosshead speed of 0.5 mm/min to ensure optimal support of the sample during the 3-point bending test where the load at which rupture then fracture occurred was recorded in Newton.

The samples subjected to a flexural strength & flexural modulus test at a crosshead speed of (0.5 mm/min) in a universal testing machine to break.

Record the maximum breaking load (P in Newton) and calculate the flexural strength (in MPa) for each specimen as follows:

FS = 3PL/ (2bd^2) Where:

P: Fracture load L: Distance between the supporting rollers (12mm)

b: Specimen width d: Specimen thickness

While flexural modulus (EF) in GPa was determined from the straight portion of the (dP/dd) slope obtained during testing and according to Equation

EF = L^3/4bt^3 (dP/dd) where:

P: Fracture load L: Distance between the supporting rollers (12mm) b: specimen width t: specimen thickness d: the displacement During testing, zirconia and hybrid ceramic micro rods exhibited minimal bending before breaking in half. For all samples, the failure line is near the center of the sample, where the load is applied.

Results

Microhardness test

Test of Normality for microhardness

The obtained values have been subjected to normality tests; Kolmogorov Smirnov & Shapiro-Wilk tests, the values were found to follow the normal distribution as follows table 3.1:

| Kolmogorov-Smirnov | Shapiro-Wilk | |||||

|---|---|---|---|---|---|---|

| Statistic | Df | Sig. | Statistic | Df | Sig. | |

| Zirconia | 0.168 | 10 | .200* | 0.95 | 10 | 0.674 |

| Cerasmart | 0.22 | 5 | 0.187 | 0.91 | 5 | 0.278 |

| Vita Enamic | 0.181 | 5 | .200* | 0.904 | 5 | 0.251 |

Table 3.1: Tests of Normality for Microhardness.

Descriptive Statistics for Microhardness

Descriptive statistics were done to the values of the tested groups. Table 3.2 shows the means, minimum and maximum, the standard deviations, and standards of errors.

| Zirconia | Cerasmart | Vita Enamic | |

|---|---|---|---|

| N | 10 | 5 | 5 |

| Mean | 1086.2 | 369.6 | 355.1 |

| Std. Deviation | 59.9329 | 146.018 | 120.961 |

| Minimum | 1011.01 | 223 | 196 |

| Maximum | 1201 | 613 | 561 |

Table 3.2 Descriptive Stats for microhardness test.

Analysis of Variance (One-way ANOVA) for micro-hardness test Groups

A one-way analysis of variance was applied to the hardness values. ANOVA test results showed statistical significance (p<0.05) of microhardness between groups. A Duncan multiple range test was performed to further investigate this difference, as shown in the table 3.3.

| Sum of Squares | Df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|

| Between Groups | 4371239.5 | 3 | 1391413.2 | 140.809 | 0 |

| Within Groups | 316537.6 | 36 | 10614.378 | ||

| Total | 4935137.1 | 39 |

Table 3.3 ANOVA Test for micro-hardness test.

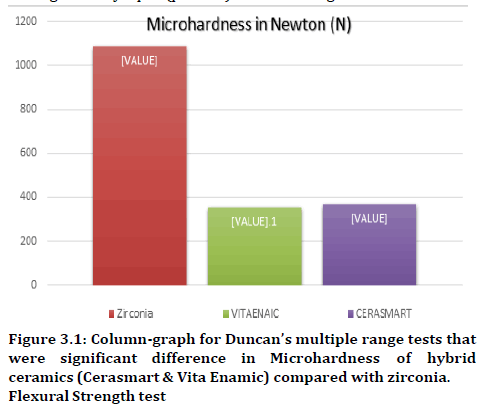

To determine the level of significance that obtained, Duncan’s post hoc test showed the micro-hardness value of zirconia groups was significantly higher than all other groups, Cerasmart & Vita Enamic was significantly equal (p ≤ 0.05) as shown in figure 3.1.

Figure 3.1: Column-graph for Duncan’s multiple range tests that were significant difference in Microhardness of hybrid ceramics (Cerasmart & Vita Enamic) compared with zirconia.

Tests of Normality for Flexural Strength Test: The values obtained subjected to normality tests, Kolmogorov- Smirnov & Shapiro-Wilk tests. The values were found to follow the normal distribution as follows in table 3.4.

| Kolmogorov-Smirnov | Shapiro-Wilk | |||||

|---|---|---|---|---|---|---|

| Statistic | Df | Sig. | Statistic | Df | Sig. | |

| Zirconia | 0.133 | 10 | 0.2 | 0.977 | 10 | 0.95 |

| Cerasmart | 0.205 | 10 | 0.2 | 0.956 | 5 | 0.715 |

| Vita Enamic | 0.215 | 10 | 0.2 | 0.906 | 5 | 0.69 |

Table 3.4: Test of normality for flexural strength test.

Descriptive Statistics for Flexural Strength.

Descriptive statistics were done to the values tested groups. Table 3.5 shows the means, minimum, maximum, and standard deviations.

| N | Minimum | Maximum | Mean | Std. Deviation | |

|---|---|---|---|---|---|

| Zirconia | 10 | 440 | 465 | 458 | 10.15229 |

| Cerasmart | 5 | 230 | 238 | 235 | 8.17646 |

| Vita Enamic | 5 | 147 | 160 | 156 | 7.24949 |

Table 3.5: Descriptive Stats for flexural strength test.

Analysis of Variance (One-Way ANOVA) for Flexural Strength

The one-way analysis of variance was applied to the flexural strength values. The ANOVA test result showed significance at P<0.05 in flexural strength between groups. The Duncan’s multiple range tests was performed to further investigate this difference as shown in table (3.6).

| Sum of Squares | Df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|

| Between Groups | 715142.5 | 3 | 218724.17 | 4257.593 | 0 |

| Within Groups | 1547 | 36 | 50.13 | ||

| Total | 746217.5 | 39 |

Table 3.6 ANOVA Test for flexural strength test.

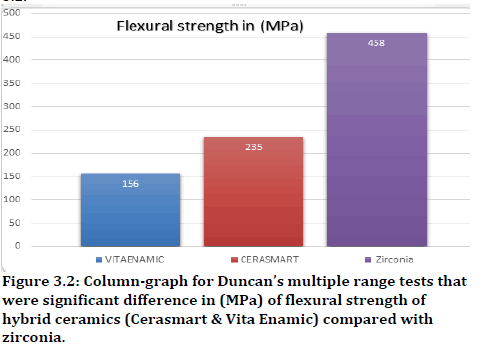

To determine the level of significance obtained, Duncan's post hoc test showed that the flexural strength values were significantly higher for the zirconia group than hybrid ceramic group, significantly flexural strength value was lower values for the Vita Enamic group. Cerasmart group has higher values compared with Vita Enamic but lower than zirconia (p≤0.05), as shown in the figure 3.2.

Figure 3.2: Column-graph for Duncan’s multiple range tests that were significant difference in (MPa) of flexural strength of hybrid ceramics (Cerasmart & Vita Enamic) compared with zirconia.

Flexural Modulus test

Tests of Normality for Flexural modulus Test: The obtained values were tested for normality, Kolmogorov-Smirnov and Shapiro-Wilk. It is found that the values obey the following normal distribution as show in Table 3.7.

| Kolmogorov-Smirnova | Shapiro-Wilk | |||||

|---|---|---|---|---|---|---|

| Statistic | Df | Sig. | Statistic | Df | Sig. | |

| Zirconia | 0.176 | 10 | .200* | 0.907 | 10 | 0.95 |

| Cerasmart | 0.236 | 5 | .200* | 0.917 | 5 | 0.579 |

| Vita Enamic | 0.186 | 5 | .200* | 0.922 | 5 | 0.498 |

Table 3.7: Test of normality for flexural modulus test.

Descriptive Statistics for Flexural modulus

Descriptive statistics were carried out for the values. The table 3.8 shows the mean, minimum, maximum and standard deviation.

| N | Minimum | Maximum | Mean | Std. Deviation | |

|---|---|---|---|---|---|

| Zirconia | 10 | 56.2 | 59.1 | 57.52 | 1.97871 |

| Cerasmart | 5 | 29.2 | 31.6 | 30.34 | 1.71251 |

| Vita Enamic | 5 | 27.8 | 32.3 | 30.16 | 1.473782 |

Table 3.8: Descriptive Stats for flexural modulus test.

Analysis of Variance (One-Way ANOVA) for Flexural modulus

One-way ANOVA applied to flexural modulus values. The results of one-way analysis of variance showed that the flexural strength between groups was significant at P<0.05, to investigate this difference further, Duncan's multiple range test was performed Table 4.9.

| Sum of Squares | Df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|

| Between Groups | 13584.477 | 3 | 5128.159 | 2180.14 | 0 |

| Within Groups | 99.201 | 36 | 2.431 | ||

| Total | 12875.678 | 39 |

Table 4.9: ANOVA Test for flexural modulus test.

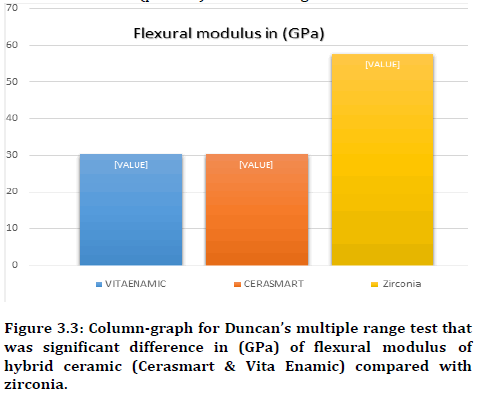

To determine the level of significance obtained, Duncan's post hoc test showed that the flexural modulus values were significantly higher for the zirconia group and significantly lower for Vita Enamic and Cerasmart groups. Hybrid ceramics was significantly equal but lower than zirconia (p ≤ 0.05) as shown in figure 3.3.

Figure 3.3: Column-graph for Duncan’s multiple range test that was significant difference in (GPa) of flexural modulus of hybrid ceramic (Cerasmart & Vita Enamic) compared with zirconia.

Discussion

Implant abutments come in many shapes and sizes. Their walls, usually made of titanium or a titanium alloy, are smooth, polished, and have straight sides. Titanium implant abutments are widely used for their optimal physical and mechanical properties, including high strength and biocompatibility. Due to their gray color, these abutments can affect the aesthetics of the final restoration In addition; titanium implants and abutments have a much higher modulus of elasticity than "bone," a difference that can cause alveolar bone to resorb in a process known as "stress shielding". Due to the excellent properties in terms of biocompatibility and aesthetics, the increasing aesthetic demand of populations has led to the manufacture of metal-free dental materials that is led to widespread use of ceramic materials, thus requiring the need for ceramic abutments, especially zirconia abutments proceed checking. High-strength ceramics, including zirconia, proved now as the best choice for the manufacture of implant abutments especially in term of esthetics and biomechanical properties. Nowadays, a new generation of hybrid materials made of ceramic and resin composites (hybrid ceramics) are also being tested as an implant abutments (hybrid abutments) beside their uses as fixed prosthesis due to their excellent properties in terms of biocompatibility and esthetics [12].

Microhardness test

test It is the ability of a material to resist deformation caused by surface penetration. Hardness remains one of the most important requirements for implant abutment materials [13]. The microhardness test results of this study demonstrated that Y-TZP zirconia hardness values were higher than that two-hybrid ceramic material (Cerasmart & Vita Enamic) that used at our study. While there was no significant differences between Cerasmart and Vita Enamic. These hardness results are in agreement with Goujat et al., 2018 who found that Y-TZP zirconium have higher mechanical properties, especially in terms of micro-hardness than polymer- infiltrated ceramics (hybrid ceramics) therefore, they concluded that Cerasmart hybrid ceramic has a lower surface hardness than zirconia ceramics [14]. For Group I (Y-TZP zirconia), the results of the current study are about (1086±5.7) consistent with the findings of Pittayachawan et al, . Their study of Vickers micro-hardness was 1044 ±75 HV [15]. Likewise, Vagkopoulou et al., reported an average Vickers microhardness value of 1170 for Y-TZP [16]. Although the microhardness values for the Vita Enamic hybrid ceramic group were average (355 ± 1.0), the results were consistent with those of Murali Ramamoorthi et al, and Ewais et al [17, 18]. He L and Swain. Described the mechanical properties of hybrid ceramics and found them to be very similar to natural dentin and enamel. This has been the goal of restoration materials for many years. Similar hardness and modulus of elasticity to tooth tissue make these materials a good choice for restorations, especially in the posterior region [19]. In testing and comparing the surface hardness of PEEK, zirconia and hybrid ceramic (Vita Enamic) crowns Stawarczyk et al., concluded that the surface hardness of PEEK is lower than that of zirconia while it was similar to that of hybrid ceramics. In addition, they found all three crowns successfully resisted physiological occlusal forces, and an in vitro study concluded that Vita Enamic could be used as an alternative crown material for fixed dentures [20]. In general, the mechanical properties of ceramic-based materials are stronger than those of polymer-based materials. The significant differences between the microhardness of 3Y-TZP zirconia, Cerasmart &Vita Enamic can be attributed to the different natural components of these materials. Zirconia is a relatively hard ceramic material, while hybrid ceramics are polymer-infiltrated ceramics that has polymer made whose surface is prone to scratches or abrasions [21]. Also, Alberto et al., compared the elasticity and surface hardness of several ceramic materials: two hybrid ceramics (Cerasmart & Vita Enamic) and zirconia, they studied micro-rods rather than crowns; they found that the surface hardness values of zirconia material was within the statistical significantly higher than the other materials, but there was no statistically significant difference between the two hybrid ceramic materials [22].

Flexural strength and Flexural modulus tests

Flexural strength of a material is a physical property denoting the ability for that material to bend. In mechanical terms, it is the ratio of stress to strain during a flexural deformation or bending. While flexural modulus it is a measure of a material’s resistance to be elastically deformed, i.e. non-permanently, when a stress is applied. The result of flexural strength test of this research proved that the flexural strength value of 3Y-TZP zirconia was significantly higher than hybrid ceramic group. Vita Enamic was significantly lower than other tested materials while the flexural strength of Cerasmart was higher than Vita Enamic but lower than Zirconia group. While the result of flexural modulus test of this research showed that the flexural modulus value of 3Y-TZP zirconia was significantly higher than hybrid ceramics, the flexural modulus value of Vita Enamic & Cerasmart groups was significally equal, and lower than zirconia (p≤ 0.05). These results has an agreement with Kohal et al. whose studying the effect of cyclic loading on flexural strength of zirconia, hybrid ceramic (Vita Enamic) and peek implant abutments [23]. Similarly, the results of flexural strength &modulus tests of our study also have an agreement with Aboushelib et al. Studied the effect of cyclic loading on flexural strength and flexural modulus of zirconia and Vita Enamic the authors concluded that zirconia has high flexural strength and flexural modulus values Vita Enamic; cyclic loading significantly reduces the flexural strength of tested materials [24]. For group I (Hybrid ceramics) He L and Swain described the mechanical properties of hybrid ceramic materials such as (Cerasmart & Vita Enamic), they found that the flexural strength and flexural modulus of these materials very similar to natural dentin and enamel which make these material good choice for restoration especially in posterior area. Also through studying the mechanical properties of human dentin and several restorative dental materials, found that the Hybrid ceramics (Vita Enamic & Cerasmart) are only materials in the test has the features elasticity of (30 GPa) a value within the range of natural human dentin (15-30 GPa) [25]. The flexural modulus value of hybrid ceramics were lower but better than 3Y-TZP zirconia groups, since the polymer network ensures flexibility, so these materials has unique structure ensures perfect balance between strength and elasticity. In comparison of hybrid ceramics to conventional resin composites polymer, Johnson AC. et al. stated the presence of ceramic nano- particles in Cerasmart and Vita Enamic did not greatly improve flexural strength of these materials, Also their results has agreement with our results that showed the flexural strength of Vita Enamic was statistically significantly lower than that of Cerasmart, while the flexural modulus of vita Enamic was statistically significantly equal [26]. Guilherme N. et al., also evaluated the flexural strength and flexural modulus of three tooth-colored implant custom abutment bonded to titanium inserts (hybrid abutment): zirconia, lithium disilicate, resin-based composite ceramic (Cerasmart) they concluded that: Zirconia abutments demonstrate high flexure load to fracture and high modulus of elasticity, Resin-based composite ceramic (hybrid ceramic) and lithium disilicate abutments showed no statistical differences [27]. Elsayed A. et al, Concluded that the excellent optical properties, good mechanical characteristics especially the flexural modulus of (Vita Enamic & Cerasmart) raised the chance of using hybrid ceramics with titanium base as hybrid implant abutments [28]. In comparison the modulus of elasticity of two different types of hybrid implant abutments, Banko glu Güngör, et al., found that the flexural modulus and flexural strength of polymer infiltrated ceramic network (hybrid ceramics) hybrid abutments was lower than zirconia hybrid abutments [29]. Furtado de Mendonca A, et al. Study the flexural strength, flexural modulus and micro-hardness of different CAD/CAM materials, Researchers compared IPS e.max CAD (lithium disilicate), ceramic based zirconia, Cerasmart (hybrid ceramics) and Vita Enamic (hybrid ceramics). As a result of that vitro study concluded that all tested materials were considered as suitable for posterior full-crown restorations, inlay, on lays and implant abutment but hybrid ceramics showed lower hardness and flexural strength compared to zirconia ceramics [30]. For group II (Y-TZP Zirconia) Ozkurt Z et al, stated that the elastic modulus of zirconia is about (210 Gpa) which is about 14 times greater than compact bone (14 Gpa). These stiff materials when used as implants do not adequately strain the bone, resulting in disuse atrophy and bone resorption [31]. Nouh I et al, studied the Mechanical behavior (flexural strength) of zirconia hybrid- abutments versus hybrid ceramics-hybrid-abutments (Cerasmart), they concluded that zirconia hybrid abutments has high flexure load to fracture values than hybrid ceramics-hybrid abutments. Also stated that zirconia abutments have double more stiffness than that of hybrid ceramics so reduce the stresses directed on implant [32].

Conclusion

The following points concluded despite the limitations of this in vitro study.

Hybrid ceramics has better elasticity than traditional zirconia since the acrylate polymer network ensures elasticity & flexibility, so these materials has unique structure ensures perfect balance between strength and elasticity. Cerasmart hybrid ceramic material has better hardness, flexural strength and flexural modulus than Vita Enamic. Hybrid ceramics especially Cerasmart is good indication for fixed prosthesis and implant abutment.

Y-TZP zirconia has higher mechanical properties in term of surface hardness and flexural strength than hybrid ceramics. Therefore, zirconia is good alternative to metal titanium in term of implant abutment because it has good esthetic & mechanical behavior.

References

- Sallam H. Influence of Cobalt Chromium Framework Fabrication Techniques on Marginal Accuracy and Fracture Behavior of Implant-Supported Metal Ceramic Bridges. Egypt Dent J 2017; 63: 1055-68.

- Thompson V, Rekow D. Dental ceramics and the molar crown testing ground. Academy Dent Mater 2014; 12: 26-36.

- Mehl Z, Al-Sanabani FA, Al-Qudami NH, et al. Use of zirconia in dentistry: An overview. Biomater J 2014; 5:1–9.

- Michailova M, Elsayed A, Fabel G, et al. Comparison between novel strength-gradient and color gradient multi layered zirconia using conventional and high-speed sintering. Mech Behav Biomed Mater J 2020; 111: 103977.

- Argyrou R, Thompson GA, Cho SH, et al. Edge chipping resistance and flexural strength of polymer infiltrated ceramic network and resin nanoceramic restorative materials. prosthet Dent J 2016; 116:397-403.

- Dirxen C, Blunck U, Preissner S, et al. Clinical performance of a new biomimetic double network material. Open Dental Journal 2013; 7: 118- 22.

- Della Bona A, Corazza PH, Zhang Y, et al. Characterization of a polymer-infiltrated ceramic-network material. Dent Mater J 2014; 30: 64-9.

- Coldea A, Swain MV, Thiel N. In-vitro mechanical evaluation of dental ceramics and polymer-infiltrated-ceramic-network materials material by sharp indentation. Mech Behav Biomed Mater J 2013; 26:34-42.

- John J. Vickers microhardnes test of dental materials. Literature review. Prosthet Dent J 23:12-4.

- Padrós R, Punset M, Molmeneu M, et al. Mechanical properties (flexural strength) of dental- restorations made by three manufacturing processes. Inf micro topo 2020; 10:1-18.

- Huerta E, Corona JE, Oliva AI, et al. Universal testing machine for mechanical properties of thin materials. Rev Mex de Fis 2010; 56; 317-22.

- Coldea A, Swain MV, Thiel N. In-vitro mechanical evaluation of dental ceramics and polymer-infiltrated-ceramic-network materials material by sharp indentation. J Mech Behav Biomed Mater 2013; 26:34-42.

- Heberling T, Fee A, Tobolski E. Minimum thickness requirements for surface hardness testing. Mater Test Evaluate 1996; 24:131-9.

- Goujat A, Abouelleil H, Colon P, et al. Surface hardness and internal fit of four CAD/CAM block materials. J prosthet dent 2018; 119: 384-389.

- Pittayachawan P, McDonald A, Petrie A, et al. The flexural strength and hardness property of YTZP dental ceramic. Dent Mater J 2007; 23:1018-29.

- Vagkopoulou T, Koutayas SO, Koidis P, et al. Zirconia in dentistry: Part 1. Discovering the surface hardness nature of an upcoming bio ceramic. European J Esthet Dent 2009; 4:130–51.

- Murali Ramamoorthi, Vivek Verma Z. Mechanical evaluation of dental biomaterials and a novel composite of Zirconia and Poly Ether Ether Ketone (PEEK) for dental implants. Dent Mater J 2015; 2:16–22.

- Ewais OH, Al Abbassy F, Ghoneim MM, et al. Novel zirconia surface treatments for enhanced osseointegration: Laboratory characterization. Inter Dent J 2014.

- He L and Swain M. A novel polymer infiltrated ceramic dental material. Dent Mater 2011; 27:527-34.

- Stawarczyk B, Liebermann A, Eichberger M. Evaluation of mechanical and optical behavior of current esthetic dental restorative CAD/CAM composite ceramics. Mech Behav Biomed Mater 2016; 55:1-1.

- Lawson NC, Bansal R, Burgess JO. Wear, strength, modulus and hardness of CAD/CAM restorative materials. Dent Mater J 2016; 32, 275-283.

- Alberto A, Pascual A, Camps I, et al. Comparative characterization of a novel cad-cam polymer-infiltrated-ceramic network. J Clin Exp Dent 2015; 7: 495-500.

- Kohal RJ, Wolkewitz M, Fabel G, et al. The effects of cyclic loading on the flexural strength of zirconium, Vita Enamic and PEEK implant abutment: An in vitro investigation. Clin Ora Imp Res 22:808–14.

- Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Evaluation of a flexural strength and modulus of composite ceramic for dental applications. J of prosthet Dent 2008; 17:538-44.

- Kinney JH, Marshall SJ, Marshall GW. The mechanical properties of human dentin: a critical review and re-evaluation of the dental literature. Crit Rev Ora Biolog Med 2003; 14:13-29.

- Johnson AC, Versluis A, Tantbirojn D, et al. Flexural strength of CAD/CAM composite and composite infiltrated ceramic occlusal veneers. Prosthet Dent J 2015; 58:107-14.

- Guilherme N Flinn BD, Zheng C, et al. Studying the flexural strength and the flexural modulus of zirconium, peek and Cerasmart restorations. Prosthet Dent J 113:205–43.

- Elsayed A, Wille S, Al-Akhali M, et al. Flexural strength and flexural modulus of vita Enamic and Zirconia implant abutments. Clin Ora Imp Res 29:20–27.

- Bankoglu Gungor M, Karakoca Nemli S, Yılmaz H, et al. Modulus of elasticity of different implant supported ceramic abutment/crown systems. Eur Ora Res 2014; 53, 80–87.

- Furtado de Mendonca A, Shahmoradi M, de Gouvêa CVD, et al. Microstructural and Mechanical Characterization of CAD/CAM Materials for Dental Restorations. J Prosthodont 2019; 28:e587–e594.

- Ozkurt Z, Kazzoglu E. Zirconia dental implants: A literature review. Oral Imp J 2011; 37:367–376.

- Nouh I, Kern M, Sabet A, et al. Mechanical behavior (flexural strength) of zirconia hybrid-abutment versus hybrid-abutments of hybrid ceramics and peek abutments: A laboratory study. Clin Ora Imp Res 2022; 30:90

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Author Info

Ehab Bassam Al-sharifee* and Ahmed Asim Saeed Al-Ali

Department of Prosthodontics, College of dentistry University of Mosul, Mosul, IraqCitation: Ehab Bassam Al-sharifee, Ahmed Asim Saeed Al-Ali, Mechanical Evaluation of Hybrid Ceramic Compared With Zirconia as an Implant Abutment Material, J Res Med Dent Sci, 2023, 11(5):53-58.

Received: 26-Apr-2023, Manuscript No. jrmds-23-90614; Accepted: 28-Apr-2023, Pre QC No. jrmds-23-90614; Editor assigned: 28-Apr-2023, Pre QC No. jrmds-23-90614; Reviewed: 12-May-2023, QC No. jrmds-23-90614; Revised: 17-May-2023, Manuscript No. jrmds-23-90614; Published: 24-May-2023