Research Article - (2022) Volume 10, Issue 8

The Impact of Adding Silanized Microcrystalline Cellulose on Some Properties of Heat-Cured Acrylic Denture Base Material

Nareman Muhannad Zaidan* and Raghdaa Kareem Jassim

*Correspondence: Nareman Muhannad Zaidan, Department of Prosthodontics, University of Baghdad, Baghdad, Iraq, Email:

Abstract

Introduction: The most widely used material for dentures fabrication is acrylic resin. However, it doesn’t fulfil all the criteria required for a good denture base material as it has an insufficient surface hardness, inadequate impact strength, low strength, and brittleness.

Aim of the study: The aim of this study was to evaluate the effect of silanized microcrystalline cellulose addition on the impact strength, surface hardness, and surface roughness of heat cured acrylic.

Materials and methods: Microcrystalline cellulose was milled and surface treated with (3-Aminopropyl) trimethoxysilane. Ninety specimens were fabricated and divided according to the tests into three main groups. Each main group was then subdivided into three subgroups: the control group and experimental groups of 1% wt. microcrystalline cellulose and 1.5% microcrystalline cellulose with ten specimens for each subgroup. Impact strength, surface hardness, and surface roughness were then tested by using Charpy impact testing machine, Shore D durometer, and Profilometer device, respectively. The results were statistically analysed using one-way ANOVA test and Bonferroni multiple comparisons test (P=0.05).

Results: The results of impact strength revealed a statistically significant increase in impact strength after incorporation of 1% wt. of silanized microcrystalline cellulose and a statistically high significant increase occurred with the addition of 1.5%. For surface hardness and surface roughness, a statistically highly significant increase encountered after incorporation of 1% wt. and 1.5% wt. of silanized microcrystalline cellulose (P ≤ 0.01).

Conclusion: Silane treated microcrystalline cellulose improves impact strength, surface hardness, and surface roughness of heat cured acrylic.

Keywords: Acrylic resin, Microcrystalline cellulose, Silane coupling agent, Impact strength, Surface hardness

Introduction

Acrylic resin is considered as the most widely used material for denture base fabrication since it was clinically evaluated and introduced as a denture base material. Walter Wright in 1937 [1]. Acrylic resin dentures have the benefits of being lightweight, inexpensive to use, stable in the oral environment, easy to repair, and have good aesthetics characteristics. However, several drawbacks such as insufficient surface hardness, low strength, brittleness, polymerization shrinkage, weak flexural, lower impact strength and low fatigue resistance create negative impact on acrylic resins [2,3]. There have been several attempts to enhance the mechanical and physical properties of acrylic resin and adding fillers for reinforcement is considered as the most reasonable and cost-effective method to enhance the properties of acrylic resin [4]. Different fillers have different effects on the acrylic resin composites properties. Those fillers can be in metal, ceramic, and polymer based materials. Over the last two decades, great attention has been paid to the renewable natural materials to be used in different applications [5]. When the natural materials are used as reinforcing material, they offer advantages such as cost effectiveness, high density, renewability, and high degree of flexibility in the work along with providing a healthier working condition [6].

Micro Crystalline Cellulose (MCC) is a natural non-fibrous white odourless powder. It is usually produced by acid hydrolysis of α-cellulose with large amounts of mineral acid [7]. Microcrystalline cellulose can be extracted from any cellulose-rich material. Wood and cotton linters are the most important feedstock employed in the manufacture of microcrystalline cellulose [8]. It can also be produced from non-woody sources including coconut husk fibers, date seeds, and olive fibres [9-11]. Microcrystalline cellulose has been used for polymer reinforcement at low concentration as it has been reported to have an elastic modulus of 25 GPA and a large surface area of several hundred [12]. One recent study reported that acrylic reinforced with microcrystalline cellulose has improved flexural properties, suggesting that, in addition to its rigidity, the high modulus and large surface area of microcrystalline cellulose may help to enhance the mechanical properties of acrylic resin, Furthermore, the simplicity with which it may be added to, mixed with, and processed with acrylic implies that it can be used in clinical applications to avoid denture fracture [13].

For the fillers, the silane treatment enhances the adherence between the natural reinforcements and matrix. The silanization treatment decreases the hydroxyl groups of the cellulosic natural fillers, which in turn reduces water sorption and improves the mechanical properties of the material [14]. (3-Aminopropyl) Trimethoxysilane (APTMS) is a bifunctional organosilane that has a reactive primary amine and a hydrolyzable inorganic trimethoxy group [15]. It binds chemically to both inorganic and organic materials and it was used successfully by many researchers to modify cellulose [16,17].

The aim of this study was to evaluate the impact strength, surface hardness, and surface roughness of heat cured acrylic resin reinforced with silanized microcrystalline cellulose (1% and 1.5% by wt.)

Materials and Methods

Milling of microcrystalline cellulose

Microcrystalline cellulose (Sigma-Aldrich Co. St Louis, MO, USA), with an average particle size of 70 µm, was milled by using a planetary ball milling machine (Yangzhou Nuoya Machinery Co., Ltd. China) for 90 minutes at a speed of 300 rpm.

Particle size analysis

The size of microcrystalline cellulose particles was evaluated after milling by using particle size analyser (Brookhaven 90 Plus nanoparticle Size Analyser, USA).

Surface modification of microcrystalline cellulose

(3-Aminopropyl) trimethoxysilane (Sigma-Aldrich Co. St Louis, MO, USA) was used for silanation of microcrystalline cellulose and this was done according to the procedure proposed by Jasim and Ismail in 2014 [18].

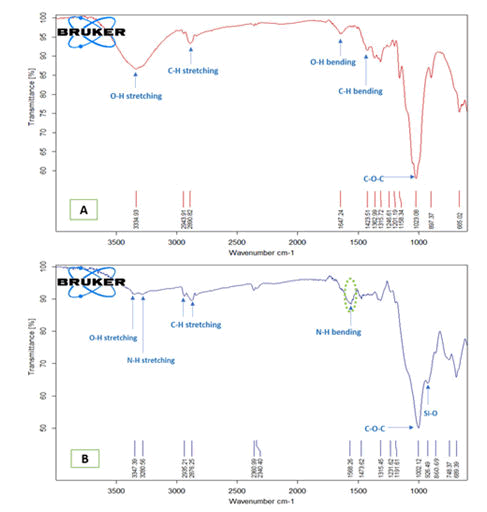

FTIR spectroscopy (ATR-FTIR, Bruker, Tensor 27, and Germany) was performed to determine if the functional groups of (3-Aminopropyl) trimethoxysilane were attached to the microcrystalline cellulose powder or not. Each spectrum was recorded in transmittance mode at a range of 4000-600 cm-1 with 4 cm-1 resolution and evaluated by Bruker OPUS software.

Study design

In this study, a total of ninety specimens were prepared and they were divided into three main groups according to the tests (impact strength test, surface hardness test, and surface roughness test). Then, all groups were further subdivided into three equal subgroups based on the percentage of microcrystalline cellulose (control group of 0% microcrystalline cellulose and experimental groups of 1% and 1.5% microcrystalline cellulose).

Test specimens preparation

Three different shaped plastic patterns were prepared by cutting plastic plates with a laser cutting machine (Modern Laser Technology Co., Ltd., Taiwan) to prepare molds for acrylic specimens. For impact strength test, plastic patterns in a bar shape with dimensions of 80 mm × 10 mm × 4 mm, in length, width, and thickness, respectively, were constructed according to ISO 179-1, 2000 [19]. For the surface hardness test, disc shaped patterns were prepared with dimensions of (40 mm in diameter and 4 mm in thickness) according to ASTM D2240 [20]. For surface roughness, instructions of the testing device were followed regarding specimen’s dimensions so bar shape specimens were prepared with dimensions of 65 mm × 10 mm × 2.5 mm, in length, width, and thickness respectively. As the conventional method used in processing the removable denture, all acrylic specimens were prepared. Type IV extra hard dental die stone (Zhermack, Italy) was used to prepare molds by investing of plastic patterns. These molds were used for packing of acrylic specimens. Control specimens were prepared by mixing powder and liquid of acrylic resin (Melioden® Heat Cure, Heraeus Kulzer, Germany) according to the manufacturer instructions. While microcrystalline cellulose incorporated specimens were prepared by adding the measured amount of silanized microcrystalline cellulose to the monomer and well dispersed using probe sonicator apparatus (Soniprep 150, England), then the monomer containing microcrystalline cellulose was immediately added to acrylic powder. When the dough stage was reached, acrylic was loaded into the stone molds and pressed by hydraulic press with pressure of (100 K.Ps/cm2) for 5 minutes. Curing of acrylic specimens were performed according to manufacturer instructions. Finally, the specimens were finished and polished (excepting those for surface roughness test) using a lathe machine (Bego, Germany). Prior to the testing procedures, all acrylic specimens were kept in distilled water for 48 hours [21].

Experimental tests

Impact strength: The impact strength test was carried by using Charpy's impact testing device (Testing machines Inc., USA) and in accordance with the procedure recommended by ISO 179-1: 2000. The specimens were placed horizontally, supported at the two ends, and struck in the middle by the 2 Joules free swinging pendulum and the absorbed impact energy was given in Joule through the scale of the device. The following equation was then used to calculate the Charpy impact strength in Kilo-joules per square meter [19].

Impact strength=E/(b.d) × 10^3

Where E is the impact energy in Joules, b is the width of the specimen in millimetres, and d is the thickness of the specimen in millimetres (Figure 1).

Figure 1: Charpy's impact testing machine.

Surface hardness

Testing was conducted by using Shore D durometer hardness tester (Elcometer®, USA) according to ASTM D2240 [20]. The instrument indented the surface of the specimen at load applied equal to 50 N and depressing time equal to 15 sec. The hardness value is displayed on the dial scale which is graduated from 0 to 100. Five points were marked for each specimen with 6 mm apart from each other and the average reading of these five points was recorded (Figure 2).

Figure 2: Shore D (durometer) hardness testing device.

Surface roughness

The microgeometry of the test specimens was studied by using the Profilometer device (TR200, Time Group Inc. Beijing, China) with accuracy of 0.001 µm. The device has a diamond sharp stylus (surface analyser) for tracing surface irregularities. The stylus is adjusted to make contact with specimens in three standardized points to obtain three readings for each specimen. The specimen was placed on stable and rigid surface then the stylus was allowed to make contact with first point and moved for a maximum distance of 11 mm from the first point. The readings appeared on the device scale and the mean of the three readings was taken as a surface roughness value. Denture bae roughness is indicated by the parameter Ra which is defined as “the mean arithmetic average of the absolute values of the roughness profile” (Figure 3) [22].

Figure 3: Profilometer device.

Statistical analysis

The data obtained from impact strength, surface hardness, and surface roughness tests were collected and analyzed with the SPSS (Statistical Package for Social Science) program [20-22].

The following statistics were employed

- Descriptive statistics which include Means, Standard deviation, Minimum value, and Maximum value.

- Inferential statistics include ANOVA (one-way analysis of variance) test which was used to evaluate the significance of difference among the mean values of all groups. If the difference was statistically significant then multiple comparisons using Bonferroni test was used to test the difference between each two groups.

Results

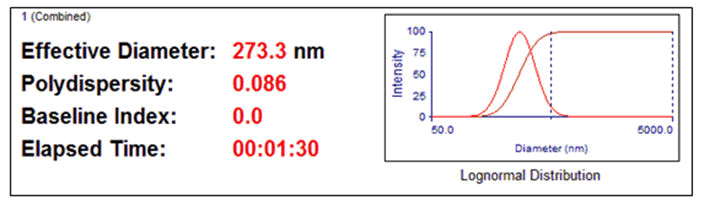

Particle size analysis

Particle size analysis verified that the effective diameter of microcrystalline cellulose powder was about 0.273 µm as shown in Figure 4.

Figure 4: Particle size analysing diagram for microcrystalline cellulose.

Fourier Transform Infra-Red (FTIR) spectroscopy

After modification of microcrystalline cellulose with (3-Aminopropyl) trimethoxysilane, a new absorption band was appeared at around 1568 cm-1 which can be assigned for the N-H bending vibration of primary amine which indicated that the functional group of (3-Aminopropyl) trimethoxysilane was successfully introduced onto the surface of microcrystalline cellulose (Figure 5). Almost all other absorption bands of (3-Aminopropyl) trimethoxysilane along with absorption bands of microcrystalline cellulose were presented in silanized microcrystalline cellulose spectrum.

Figure 5: FTIR spectra of A) pure microcrystalline cellulose and B) modified microcrystalline cellulose.

Impact strength test

The results showed that the highest mean value of impact strength was related to 1.5% microcrystalline cellulose (11.205 KJ/m2) followed by 1% microcrystalline cellulose with mean value of (10.5488 KJ/m2), while the lowest mean value of impact strength was obtained with control group (9.8873 KJ/m2) (Table 1).

| Groups | N | Mean | SD | Minimum | Maximum | F test | Signature |

|---|---|---|---|---|---|---|---|

| Control | 10 | 9.8873 | 0.69066 | 9.02 | 11.13 | 6.437 | 0.005 |

| 1% MCC | 10 | 10.5488 | 1.02771 | 9.43 | 12.07 | ||

| 1.5% MCC | 10 | 11.205 | 0.70147 | 9.91 | 12.02 |

Table 1: Descriptive analysis and one-way ANOVA test for impact strength data (KJ/m2).

The calculated P value of one-way (ANOVA) test was (0.005) and suggested a statistically highly significant difference among the studied groups. Further statistical analysis was made by using Bonferroni test and revealed a statistically highly significant difference between control group and 1.5% microcrystalline cellulose group, while a non-significant difference was observed between control group and 1% microcrystalline cellulose group and between 1% and 1.5% microcrystalline cellulose groups (PË?0.05) (Table 2).

| (I) Groups | (J) Groups | Mean Difference (I-J) | Signature | 95% Confidence Interval | |

|---|---|---|---|---|---|

| Lower bound | Upper bound | ||||

| Control | 0.01 | -0.6615 | 0.249 | -1.5994 | 0.2764 |

| 0.015 | -1.31840* | 0.004 | -2.2563 | -0.3805 | |

| 0.01 | 0.015 | -0.6569 | 0.255 | -1.5948 | 0.281 |

| *The mean difference is significant at the 0.05 level. | |||||

Table 2: Bonferroni multiple comparisons test for impact strength.

Surface hardness test

The results of surface hardness test showed that both experimental groups (1% and 1.5% microcrystalline cellulose) had a higher mean value than control group and 1.5% microcrystalline cellulose group showed the highest mean value of 86.9815. Statistical analysis using one-way ANOVA test showed a statistically highly significant difference among the mean values of the study groups as shown in Table 3.

| Groups | N | Mean | S.D | Minimum | Maximum | F test | Signature |

|---|---|---|---|---|---|---|---|

| Control | 10 | 85.72 | 0.57504 | 85 | 86.6 | 8.257 | 0.002 |

| 1% MCC | 10 | 86.794 | 0.9585 | 85.05 | 87.93 | ||

| 1.5% MCC | 10 | 86.9815 | 0.65879 | 85.9 | 88 |

Table 3: Descriptive analysis and one-way ANOVA test for surface hardness data.

Post hoc analysis using Bonferroni test revealed a statistically highly significant difference between each two tested groups (P ≤ 0.01), except between 1% and 1.5% microcrystalline cellulose groups which showed a non-significant difference (PË?0.05) (Table 4) [26].

| (I) Groups | (J) Groups | Mean Difference (I-J) | Sig. | 95% Confidence Interval | |

|---|---|---|---|---|---|

| Lower Bound | Upper Bound | ||||

| Control | 0.01 | -1.07400* | 0.01 | -1.9291 | 0.2189 |

| 0.015 | -1.26150* | 0.002 | -2.1166 | -0.4064 | |

| 0.01 | 0.015 | -0.1875 | 1 | -1.0426 | -0.6676 |

| *The mean difference is significant at the 0.05 level. | |||||

Table 4: Bonferroni Multiple comparison test for surface hardness.

Surface roughness test

Results of surface roughness test demonstrated a marked decrease in the mean value of surface roughness for experimental groups (1% and 1.5% microcrystalline cellulose) as compared to the control group and 1% microcrystalline cellulose group showed the lowest mean value of 1.3529 µm. ANOVA test demonstrated a statistically highly significant difference among the studied groups. Further statistical analysis by using Bonferroni test revealed a statistically highly significant difference among all studied groups (P ≤ 0.01) (Tables 5 and 6).

| Groups | N | Mean | S.D | Minimum | Maximum | F test | Signature |

|---|---|---|---|---|---|---|---|

| Control | 10 | 1.9323 | 0.03179 | 1.88 | 1.98 | 192.068 | 0 |

| 1% MCC | 10 | 1.3529 | 0.05808 | 1.26 | 1.43 | ||

| 1.5% MCC | 10 | 1.5061 | 0.09846 | 1.35 | 1.68 |

Table 5: Descriptive analysis and one-way ANOVA test for surface roughness data.

| (I) Groups | (J) Groups | Mean difference (I-J) | Signature | 95% confidence interval | |

|---|---|---|---|---|---|

| Lower bound | Upper bound | ||||

| Control | 0.01 | .57940* | 0 | 0.5012 | 0.6576 |

| 0.015 | .42620* | 0 | 0.348 | 0.5044 | |

| 0.01 | 0.015 | -.15320* | 0 | -0.2314 | -0.075 |

| *The mean difference is significant at the 0.05 level. | |||||

Table 6: Multiple comparison of surface roughness between groups using Bonferroni.

Discussion

Heat cured acrylic is the material that is most commonly used as a denture base material, but its use is associated with some disadvantages such as poor mechanical properties. Several studies have been conducted to enhance the mechanical and physical properties of acrylic resin by copolymerization, adding of cross-linking agents, and reinforcement [23]. This study had been made as an attempt to improve some of the mechanical and physical properties of acrylic denture base material by incorporation of silanized microcrystalline cellulose which has many applications in miscellaneous industrial fields such as pharmaceutical, food, composites, paints, and cosmetic industries [24].

Impact strength

Impact strength of denture base resin can be defined as “the energy required to fracture a material under the impact force” and it is an essential characteristic of dentures that tend to fracture if it is accidently dropped from the patient on a hard surface. Also, denture may fracture in situ if the patient has an accident involving facial region; in this case the denture fragments may be embedded into the soft tissue or may be inhaled [25].

The results of impact strength test revealed a statistically highly significant increase in the values of impact strength after incorporation of silanized microcrystalline cellulose as compared to the control group. This can be attributed to the use of silane coupling agent for treating of microcrystalline cellulose particles which enhanced the compatibility and improved the inter facial bonding between microcrystalline cellulose and acrylic which in turn prevent crack propagation [26]. Also, the crack propagation could be slower as a result of crack deflection at the strong uniformly dispersed microcrystalline cellulose crystals [27]. On the other hand, the high surface area and relatively small size and low concentration of microcrystalline cellulose helped in a well dispersion of the fillers in resin matrix and this positively affected the impact strength [28].

Surface hardness

Surface hardness is defined as the resistance of a material to the localized permanent plastic deformation [29]. Hardness of the denture is an indicative to the ease of cutting, finishing, and polishing and also influence the resistance of the denture to in-service scratching that usually occurs during cleaning of denture and may affect fatigue strength and resulting in premature failure [30].

In this study surface hardness of acrylic specimens was significantly increased after incorporation of silanized microcrystalline cellulose. This can be explained by the stiff nature of the microcrystalline cellulose crystals that increased the polymer matrix rigidity [31]. Furthermore, surface treatment with silane coupling agent helped in increasing the interfacial adhesion between microcrystalline cellulose and polymer matrix and led to good dispersion and distribution of particles in matrix which in turn positively affected the surface hardness [26].

Surface roughness

Surface roughness can be defined as surface imperfections that are finely spaced and their height, width, and direction determine the general surface pattern [32]. Increased surface roughness has a negative impact on the esthetic and hygiene of denture as it facilitates bacterial plaque and staining development on the denture. Also, increasing surface roughness encourages Candida albicans adherence which has a destructive effect on oral health [33].

The results of the present study demonstrated a reduction in surface roughness after addition of microcrystalline cellulose and this reduction was highly significant for both experimental groups. This might be due to the relatively small size of microcrystalline cellulose particles which accumulated on the surface of acrylic resin and filled the surface micro spaces. In addition, the use of (3-Aminopropyl) trimethoxysilane for surface treatment of microcrystalline cellulose increased bonding between the fillers and resin matrix so that chipping of particles away from the surface of modified polymer during deflasking became difficult leading to reduction of surface roughness [34].

Conclusion

Within the limitations of this study, it can be concluded that the incorporation of silane treated microcrystalline cellulose to heat cured acrylic has positive impacts on the material by increasing the impact strength, surface hardness, and surface smoothness of the material.

Conflict of Interest: No

Source of Funding: Self-funded

Ethical Clearance: Not Required

References

- John J, Gangadhar SA, Shah I, et al. Flexural strength of heat-polymerized polymethyl methacrylate denture resin reinforced with glass, aramid, or nylon fibers. J Prosthet Dent 2001; 86:424-427.

- Gad MM, Abualsaud R. Behavior of PMMA denture base materials containing titanium dioxide nanoparticles: A literature review. Int J Biomater 2019; 1-14.

- Sheng TJ, Shafee MF, Ariffin Z, et al. Review on poly-methyl methacrylate as denture base materials. Malays J Microsc 2018; 14:1-16.

- Rajul V, Romesh S. Denture base materials: Some relevant properties and their determination. Int J Oral Health Dent 2015; 1:1-3.

- Natarajan K, Balasubramanya PC. Mechanical and morphological study of coir fibre reinforced modified epoxy matrix composites. Int J Emerg Technol Adv Eng 2013; 3:583-587.

- Venkateshappa SC, Bennehalli B, Kenchappa MG, et al. Flexural behaviour of areca fibres composites. Bioresources 2010; 5:1846-1858.

- Macuja JCO, Ruedas LN, Espana RCN, et al. Utilization of cellulose from luffa cylindrical fibre as binder in acetaminophen tablets. Adv Environ Chem 2015; 5:1-8.

- Thoorens G, Krier F, Leclercq B, et al. Microcrystalline cellulose, a direct compression binder in a quality by design environment-A review. Int J Pharm 2014; 473:64-72.

- Abdullah NA, Sainorudin MH, Rani MSA, et al. Structural, morphological and thermal properties of microcrystalline cellulose extracted from coconut husk fiber. Polimery 2021; 66:187-192.

- Abu-Thabit NY, Judeh AA, Hakeem AS, et al. Isolation and characterization of microcrystalline cellulose from date seeds (Phoenix dactylifera L.). Int j Biol Macromol 2020; 155:730-739.

- Kian L, Saba N, Jawaid M, et al. Characterization of microcrystalline cellulose extracted from olive fibre. Int J Biol Macromol 2020; 156:347-353.

- Mohamad Haafiz MK, Hassan A, Zakaria Z, et al. Isolation and characterization of microcrystalline cellulose from oil palm biomass residue. Carbohydr Polym 2015; 93: 628-634.

- Rahaman AA, John J, Mani SA, et al. Effect of thermal cycling on flexural properties of microcrystalline celluloseâ?reinforced denture base acrylic resins. J Prosthodont 2019; 29: 611-616.

- Ouarhim W, Zari N, Bouhfid R, et al. Mechanical performance of natural fibresâ??based thermosetting composites. Mech Phys Test Biocomposit Fibre-Reinforced Composit Hybrid Composit Woodhead 2019; 12:43-60.

- Vo-Dinh T. Nanotechnology in biology and medicine: Methods, devices, and applications. CRC Press. 2017.

- Bessa W, Trache D, Derradji M, et al. Effect of silane modified microcrystalline cellulose on the curing kinetics, thermo-mechanical properties and thermal degradation of benzoxazine resin. Int J Biol Macromol 2021; 180:194-202.

- Kono H, Uno T, Tsujisaki H, et al. Nanofibrillated bacterial cellulose modified with (3-aminopropyl) trimethoxysilane under aqueous conditions: applications to poly(methyl methacrylate) fibre-reinforced nanocomposites. ACS Omega 2020; 5:29561-29569.

- Jasim BS, Ismail IJ. The effect of silanized alumina nanofillers addition on some physical and mechanical properties of heat cured polymethyl methacrylate denture base material. J Baghdad Coll Dent 2014; 26:18-23.

- Annual book of ASTM standard, D2240, Standard test method for plastics properties-Durometer hardness 2003; 1-12.

- American Dental Association Specification No.12. Guide to dental materials and devices. Chicago 1999; 32.

- Taylor R, Maryan C, Verran J, et al. Retention of oral microorganisms on cobalt-chromium alloy and dental acrylic resin with different surface finishes. J Prosthet Dent 1998; 80:592-597.

- Mallikarjuna HBM, Sharaz S, Harleen S, et al. Effect of reinforcement using stainless steel mesh, glass fibers, and polyethylene on the impact strength of heat cure denture base resin. J Int Oral Health 2015; 7:71-75.

- Hindi SSZ. Microcrystalline cellulose: Its processing and pharmaceutical specifications. BioCrystals J â??2016; 1: 26-38.

- Mccabe JF, Walls AWG. Applied dental materials. Wiley-Blackwell. 2013

- Karadi R, Hussein B. Effect of modified nanohydroxyapatite fillers addition on some properties of heat cured acrylic denture base materials. J Baghdad Coll Dent 2017; 29:49-54.

- Pichandi S, Rana S, Parveen S, et al. A green approach of improving interface and performance of plant fibre composites using microcrystalline cellulose. Carbohydr Polym 2018; 197:137-146.

- Gupta N, Brar BS, Woldesenbet E, et al. Effect of filler addition on the compressive and impact properties of glass fiber reinforced epoxy. Bull Mater Sci 2001; 24:219-223.

- Tanzi MC, Farè S, Candiani G, et al. Mechanical properties of materials. In: Tanzi MC, Fare S, Candiani G. Foundations of Biomaterials Engineering. Academic Press 2019; 105-136.

- Powers J, Sakaguchi R, Ferracane J, et al. Craigâ??s restorative dental material. St. Louis, Missouri: Elsevier. 2019.

- Rathnayake WSM, Karunanayake L, Samarasekara AMPB, et al. Fabrication and characterization of polypropylene microcrystalline cellulose based composites with enhanced compatibility. Moratuwa Eng Res Conf 2019; 354-359.

- Anusavice KJ, Phillips RW, Shen C, et al. Phillips' science of dental materials. St. Louis, Missouri, Elsevier/Saunders. 2013.

- Abdulrazzaq HT, Ali MMM. The effect of glass flakes reinforcement on the surface hardness and surface roughness of heat-cured poly (methyl methacrylate) denture base material. J Baghdad Coll Dent 2015; 325:1-5.

- Ahmed AG, Ismail IJ. Evaluation the effect of addition of plasma treated polypropylene fiber and silanized silicon dioxide nanoparticles composite on some properties of heat-polymerized polymethylmethacrylate. J Baghdad Coll Dent 2016; 325:1-8.

- Ahmed AG, Ismail IJ. Evaluation the Effect of Addition of Plasma Treated Polypropylene Fiber and Silanized Silicon Dioxide Nanoparticles Composite on Some Properties of Heat-Polymerized Polymethylmethacrylate. J Baghdad Coll Dent 2016; 325:1-8.

Author Info

Nareman Muhannad Zaidan* and Raghdaa Kareem Jassim

Department of Prosthodontics, University of Baghdad, Baghdad, IraqCitation: Nareman Muhannad Zaidan, Raghdaa Kareem Jassim, The Impact of Adding Silanized Microcrystalline Cellulose on Some Properties of Heat-Cured Acrylic Denture Base Material, J Res Med Dent Sci, 2022, 10 (8): 011-018.

Received: 20-May-2022, Manuscript No. JRMDS-22-43971; , Pre QC No. JRMDS-22-43971; Editor assigned: 23-May-2022, Pre QC No. JRMDS-22-43971; Reviewed: 06-Jun-2022, QC No. JRMDS-22-43971; Revised: 25-Jul-2022, Manuscript No. JRMDS-22-43971; Published: 01-Aug-2022