Research Article - (2021) Volume 9, Issue 12

Assessment of Friction and Surface Roughness of a Novel Orthodontic Wire FlexyBlueTitanium. (An in vitro comparative study)

Ali Alsaffar* and Shahbaa A. Mohammed

*Correspondence: Ali Alsaffar, Department of Orthodontics, College of Dentistry, University of Baghdad, Baghdad, Iraq, Email:

Abstract

Introduction: Friction plays a role in reducing the efficiency of orthodontic tooth movement, so it is necessary to understand the effect of friction and the amount of force needed to overcome its impact on biological tissue response and archwireguided tooth movement. Aim: the purpose of this study is to compare between two different wires: NiTi, Blue NiTi and CuNiTi by measuring the sliding friction and surface roughness. Materials and Methods: specimens were divided into nine groups (six specimens each) the groups were classified according to the type of the wire and treatment condition (as received, thermocycling of 5000 cycle, distilled water aging for 1month). The groups were tested for sliding friction in dry condition. Surface roughness of five samples of each group was examined by means of atomic force microscope. The data were analyzed by ANOVA, Post Hock Tukey’s test for parametric tests, and Kruskal-Wallis, pairwise comparison test for non-parametric tests. Results: showed statistical significant difference among archwires in condition of as received and thermal-cycling (NiTi had generates higher sliding friction compared with BlueNiTi and CuNiTi) with non-significant difference among the wires in distilled water condition. For aging conditions, there was statistically significant difference among conditions in both NiTi and CuNiTi wires (higher frictional resistance generated after thermal aging), while there was non-significant difference among conditions in case of BlueNiTi wire. Conclusion: it is recommended to use BlueNiTi archwires during the first stage of orthodontic treatment as it has the lowest change in friction behavior after aging.

Keywords

Niti, BlueNiti, CuNiTi, Thermo-cycling, Distilled water

Introduction

Orthodontic tooth movement is related to a mechanotherapy involving the movement of brackets along the archwire, frictional sliding resistance at the bracket-wire interface may restrict the movement and prevent the achievement of optimal force levels in the supporting tissues, As the investigators implied that using proper magnitudes of force during orthodontic treatment results in optimal biologic tooth movement.

Friction, defined as the force that resists the movement of two surfaces along one another, in which the bracket slides over the archwire, as it was found that nearly 50% of the applied force is dissipated to overcome frictional sliding resistance, high frictional forces resulting from the interaction between the bracket and the guiding archwire affect treatment outcomes and duration in a negative way, thus, decreasing frictional resistance will benefit hard and soft tissue response to get an optimal tooth movement.

Other factors that influence friction directly or indirectly include features of archwire and bracket such as the dimension and material which were investigated by.

Friction reduction can minimize the total treatment time and anchorage loss, it can be achieved by decreasing friction coefficient of wire and bracket or by reducing the ligation force.

Materials of archwire affect its characteristics such as stiffness, formability, Springback, and friction coefficient; desirable characteristics can provide optimal performance, surface roughness is an important characteristic that alters the behavior of the archwires as it plays a role in determining the friction, surface contact, effectiveness of archwire-guided tooth movement, biocompatibility and hygiene, and thereby, the quality of orthodontic treatment.

Intraorally placed orthodontic materials exhibit a pattern of continuous reactions with the environment of the oral cavity, as intraoral constituents such as saliva impose a sturdy effects on their reactive status which might alter the morphological, structural and compositional characteristics of the material, subsequently affecting the force delivery, super elasticity and fracture of the alloys.

Many surface treatments had been adopted for surface passivation and reduction of the alloy corrosion, as electropolishing and oxidation in air at high temperature. regarding air oxidation at high temperatures, NiTi specimens treated at different periods of time showed yellow/gold, purple/blue, dark blue and light (sky) blue colors. These colors are typical of anodic films on titanium of thickness increasing between 20-30 and 60-80 nm. Surface modifications aimed at enhancing corrosion behavior, biocompatibility and surface roughness.

The orthodontic materials are developing and many companies try to enhance the archwire characteristics to meet the ideal features with optimal performance. Recently, Orthometric Company developed (FlexyBlue-Ti) Nickel Titanium wire in which claims that is had a smoother and more homogeneous surface with a lower friction than any nickel titanium wire.

Thus the aim of this study is to compare between: NiTi and Blue NiTi wires by measuring the sliding friction and surface roughness.

Material and Method

Materials

Three types of archwires were used in this study, preformed round 0.016-in conventional nickel titanium, FlexyBlue-Ti nickel titanium and copper nickel titanium (Orthometric, Brazil). 50 mm of each wire was cut from almost straight end of the archwire, a total of 54 straight archwire pieces, 18 of each type of archwire. Single type of bracket were used (Dentaurum equilibrium®2) of lower left central incisor.

Specimen preparation

A total of 162 brackets were divided into 9 groups (6 specimen each), each specimen is composed of 3 brackets attached with cyanoacrylate adhesive to a uniform acrylic block that was designed and cut by computerized numerical control CO2 laser cutting machine, by which bracket positions are also scratched and marked, the distance between the middle of one bracket to another is (11 mm) the peripheral brackets in the middle of the horizontal line of the acrylic bar and the middle bracket is (2 mm) higher than the other brackets to get a three vertically unaligned brackets, in order to simulate a segment of unleveled dental arch. Wires of each group were secured into the bracket slot with elastic ligatures. 18 specimens (6 of each archwire type) were tested in as received condition, the rest were passed thought in-vitro aging procedure as following: 18 specimens (6 of each archwire type) underwent thermocycling and 18 specimens (6 of each archwire type) underwent aging in distilled water.

In vitro aging

Throughout the aging procedure, the deflected wires inside the specimen brackets were maintained by elastics ligatures and subjected to two different aging regimens as following:

- Thermo-Cycling (TC): 18 specimens (six specimen of each archwire type) will be subjected to thermal-cycling of 5,000 cycles between an elevated temperature of 55°C and a nominal temperature of 5°C with dwelling times of 30 Seconds each immersion. Then after thermocycling was finished, the specimens were air dried and tested for sliding friction.

- Distilled Water Storage (DW): 18 specimens (six specimen of each archwire type) will be stored in deionized water at 37°C for 30 days by means of laboratory water bath. Then after incubation was finished the specimens were air dried and tested for sliding friction.

Sliding friction test

The 54 archwire pieces that were prepared and air dried (18 NiTi and 18 FlexyBlueTi), were tested for sliding friction by means of instron universal testing machine, every wire piece was tested for sliding friction for one time only on a single specimen.

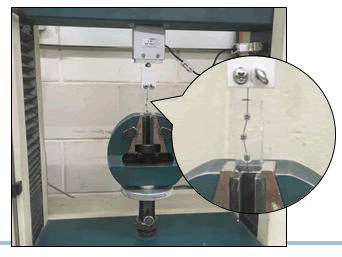

The acrylic block with brackets attached was gripped firmly by the lower end of the (Instron Tinius Olsen) universal testing machine and the arch wire is attached directly to a clamp with 10 N load cell at upper end of the machine as seen in Figure 1. This machine will measure the tensile force needed to slide 10 mm of the wire over the test specimen brackets for 2 minutes, at a speed of 5 mm per minute. The maximum frictional force value acquired in the course of the range of motion represents the static friction noted at the beginning of the movement, which was measured and recorded in Newton; all measurements will be performed under dry conditions at room temperature according to, with a controlled temperature of about 33° ± 1 (Figure 1).

Figure 1:Specimen of the test attached to 10 N load cell of Instron tinius olsen universal testing machine to test frictional resistance.

Surface roughness test

The Surface roughness of 45 wires, five wires of each group were checked with Atomic force microscopy, each wire was checked for surface roughness from three different points taking the average value for each wire. It is the preferred noninvasive and nondestructive optical method in the study of surface qualities of orthodontic materials in Nano scale, ensuring no damage to samples and facilitating correct understanding (giving quantitative and qualitative height measurements), without the need for any sample pretreatment.

The needle tip of the device moves over the wire surface being examined to a distance of few ηm, with the movement of the needle tip up and down causing a deflection of the cantilever during which a complex processing of electrical signals collected by the cantilever probe which in turn produces the final image (Figure 2).

Figure 1:Age distribution of all cases (N=49).

Statistical analysis

The statistical analysis was done by computer software (SPSS, version 25). Shapiro-wilk test was used for testing the normality of distribution of collected data. The data were analyzed by one way ANOVA, Post Hock Tukey’s test for parametric tests, and Kruskal-Wallis, Pairwise comparison test for non-parametric tests. Statistical significance was considered for p-vlaue <0.5.

Results

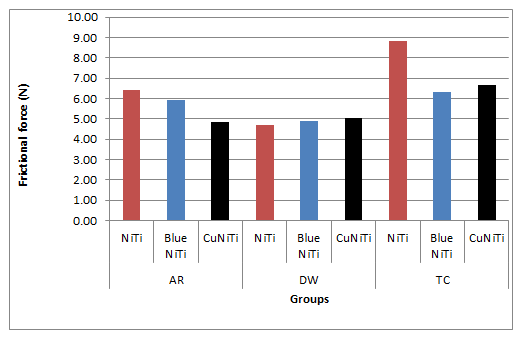

Assessment of friction

Table 1 shows the means, standard deviations, minimum, and maximum values of the frictional forces (in grams). NiTi archwire had the highest friction in both conditions (as received and thermo-cycling). Amount of friction was increased for all archwires after TC in comparison with same type of archwire in other conditions, while DW aging decreases amount of friction for both NiTi and BlueNiTi (Table 1).

Table 1: Descriptive statistics of frictional forces (g) among arch wires in the same condition, and of the same arch wire in different conditions.

| Condition | Archwires | No. | Mean | S.D. | Min. | Max. |

|---|---|---|---|---|---|---|

| AR | NiTi | 6 | 6.43 | 0.62 | 5.75 | 7.08 |

| Blue NiTi | 6 | 5.92 | 1.38 | 4.04 | 7.31 | |

| CuNiTi | 6 | 4.84 | 0.51 | 3.93 | 5.42 | |

| DW | NiTi | 6 | 4.71 | 0.61 | 3.9 | 5.58 |

| Blue NiTi | 6 | 4.87 | 0.63 | 3.75 | 5.59 | |

| CuNiTi | 6 | 5.04 | 0.39 | 4.34 | 5.4 | |

| TC | NiTi | 6 | 8.8 | 1.06 | 7.5 | 9.95 |

| Blue NiTi | 6 | 6.33 | 0.83 | 5.33 | 7.75 | |

| CuNiTi | 6 | 6.67 | 0.6 | 5.89 | 7.46 | |

| Archwires | State | No. | Mean | S.D. | Min. | Max. |

| NiTi | AR | 6 | 6.43 | 0.62 | 5.75 | 7.08 |

| DW | 6 | 4.71 | 0.61 | 3.9 | 5.58 | |

| TC | 6 | 8.8 | 1.06 | 7.5 | 9.95 | |

| Blue NiTi | AR | 6 | 5.92 | 1.38 | 4.04 | 7.31 |

| DW | 6 | 4.87 | 0.63 | 3.75 | 5.59 | |

| TC | 6 | 6.33 | 0.83 | 5.33 | 7.75 | |

| CuNiTi | AR | 6 | 4.84 | 0.51 | 3.93 | 5.42 |

| DW | 6 | 5.04 | 0.39 | 4.34 | 5.4 | |

| TC | 6 | 6.67 | 0.6 | 5.89 | 7.46 |

AR: As received, DW: Deionized water, TH: Thermo-cycling

Table 2 shows a comparison of frictional force among archwires in the same condition using one-way ANOVA test, which showed a significant difference (P<0.05) among archwires in condition of as received and thermo-cycling, while a non-significant difference among the wires in condition of distilled water (Table 2).

Table 2: Shows a comparison of frictional force among archwires.

| Archwires | State | F-test | p-value |

|---|---|---|---|

| NiTi | AR | 40.17 | 0 |

| DW | |||

| TC | |||

| Blue NiTi | AR | 3.357 | 0.062 |

| DW | |||

| TC | |||

| CuNiTi | AR | 23.095 | 0 |

| DW | |||

| TC |

Tukey’s test was performed to verify between which wires was the difference as in Table 3, showing a significant difference (P<0.05) between NiTi and CuNiTi subgroups in condition of as-received, and a highly significant difference (P<0.01) between NiTi subgroup and CuNiTi and BlueNiTi subgroups in condition of thermo-cycling (Table 3).

Table 3: ANOVA test for comparison of frictional force among archwires in the same condition.

| State | Archwires | F-test | p-value |

|---|---|---|---|

| AR | NiTi | 4.575 | 0.028 |

| Blue NiTi | |||

| CuNiTi | |||

| DW | NiTi | 0.523 | 0.603 |

| Blue NiTi | |||

| CuNiTi | |||

| TC | NiTi | 14.732 | 0 |

| Blue NiTi | |||

| CuNiTi |

Table 4 shows a comparison of frictional force among three different conditions for the same archwire using one-way ANOVA test, which showed a very highly significant difference (P=0.00) among different conditions in both NiTi and CuNiTi wires, while a non-significant difference in the three different conditions in BlueNiTi wire (Table 4).

Table 4: Post Hock Tukey’s test.

| State | Archwires | p-value | ||

|---|---|---|---|---|

| As received | NiTi | Blue NiTi | 0.616 | |

| CuNiTi | 0.025 | |||

| Blue NiTi | CuNiTi | 0.144 | ||

| Thermal | NiTi | Blue NiTi | 0 | |

| CuNiTi | 0.002 | |||

| Blue NiTi | CuNiTi | 0.775 | ||

Tukey’s test was performed to verify between which condition was the difference as in Table 5, showing a very highly significant difference (P=0.00) between the TC condition and AR and DW conditions, in both NiTi and CuNiTi wires, while, a highly significant difference between AR and DW in case of NiTi wires (Table 5).

Table 5: Post Hock Tukey’s test.

| Archwires | State | Mean Difference | p-value | |

|---|---|---|---|---|

| NiTi | AR | DW | 1.718 | 0.005 |

| TC | -2.377 | 0 | ||

| DW | TC | -4.095 | 0 | |

| CuNiTi | AR | DW | -0.198 | 0.783 |

| TC | -1.83 | 0 | ||

| DW | TC | -1.632 | 0 | |

Assessment of surface roughness

Table 6 shows the medians, minimum and maximum values of the Roughness Average (Ra) for the wires in every condition (in nm); Surface roughness was increased for all types of archwires after thermo-cycling (Table 6).

Table 6: Descriptive statistics of the Ra (nm) of the wires.

| Max. | Min. | Median | condition |

|---|---|---|---|

| 34.1 | 8.92 | 24.08 | AR |

| 68.36 | 28.54 | 40.8 | |

| 82.79 | 20.24 | 48.62 | |

| 69 | 19.9 | 41.18 | DW |

| 131.22 | 21.34 | 26.61 | |

| 67.08 | 19.17 | 32.23 | |

| 77.35 | 33.67 | 46.29 | TC |

| 81.11 | 27.01 | 52.59 | |

| 148 | 59.89 | 79.8 |

Table 7 shows a comparison among surface roughness of the three archwires in same conditions using Kruskal-Wallis test, showing a non-significant difference among the wire (Table 7).

Table 7: Kruskal-Wallis test for the comparison of surface roughness among different archwires in the same condition.

| p-value | d.f | Kruskal wallis Test | Archwire |

|---|---|---|---|

| 0.054 | 2 | 5.84 | NiTi |

| 0.336 | 2 | 2.18 | Blue NiTi |

| 0.046 | 2 | 6.14 | CuNiTi |

Table 8 shows a comparison of surface roughness of the same archwire type among different conditions using Kruskal-Wallis test, showing a significant difference (P<0.05) among conditions in CuNiTi wires (Table 8).

Table 8: Kruskal-Wallis test for the comparison of surface roughness of the same wire in different condition.

| p-value | d.f | Kruskal wallis Test | Condition |

|---|---|---|---|

| 0.05 | 2 | 6 | AR |

| 0.932 | 2 | 0.14 | DW |

| 0.087 | 2 | 4.88 | TC |

Discussion

Study design

The brackets used in this study were the lower central incisor stainless steel brackets of Roth prescription as it had a torque of -1° and tip of 0° (Dentaurum equilibrium®2). The archwires used in this study were preformed 0.016 inch round wires (Orthometric, Brazil), as light gauge archwires apply light forces and are recommended during the alignment and leveling phase. This study was designed to compare three types of nickel titanium wires, as the material of these archwires are flexible and could be put to use during the first stage of the orthodontic treatment. The design of the three brackets with the middle bracket 2 mm higher was used to simulate a segment of vertically unleveled dental arch.

Elastic ligature ligation was used to fix the wires in place (American Orthodontics, USA), as it is the most common ligation type used in the orthodontic clinics; all elastic ligatures were ligated in figure of “O” pattern; all ligation were done by the same operator for standardization and to reduce the possibility of bias such as higher ligation force produced by tight ligation which could increase frictional resistance. Stainless steel ligatures were not used because of the difficulty to attain standardized ligation force even for a well-trained operator according to.

Artificial aging

Thermo-cycling was done mimic the temperature fluctuations of the oral cavity and its effect on orthodontic materials, which can be affected by many factors as body temperature, mouth breathing condition, whether mouth is opened or closed, surrounding temperature and while eating or drinking. Intraoral temperature ranged from 5.6°C to 58.5°C with reference to the intraoral temperature variation measured.

Distilled water incubation for 30 days at 37°C was done to simulate the intraoral clinical use of archwire for at least 1 month within the regular body temperature.

Friction and roughness test

Instron Tinius Olsen universal testing machine was used for frictional resistance test by tensile pulling the wire through the brackets at a speed of 5 mm/minute, as other researchers found that the measurement will not change significantly when using speed ranged between 0.5 and 50 mm/min. In this study, only the static frictional forces were measured and the kinetic friction was not considered, as stated by kinetic friction is considered irrelevant in orthodontic movement of teeth for all practical purposes due to the fact that the continuous motion of a tooth along the wire rarely if ever occurs, as the tooth displaces in a small increments that develops in a manner of cyclical tipping and uprighting during orthodontic movement.

Atomic Force Microscope (AFM) was used to evaluate the variations in surface roughness of different commercial NiTi archwires, using the parameter, Roughness Average (Ra) was used for the assessment of surface roughness; Ra is representation of the deviations of the height from the mean surface. AFM was verified as a favorable technique for the evaluation and investigation of surface qualities of orthodontic archwires, due to ease of use without requiring any pre-treatment protocol and provide a quantitative measurement of the roughness with a 3D configuration of the Nano-scale irregularities.

Regarding the effect of different archwire material on friction, the results in table 3 and table 4 showed that the nickel titanium archwire had a higher friction than the other wires in condition of AR and TC with highly significance difference when compared with CuNiTi in both conditions, while a very highly significant difference when compared with BlueNiTi in condition of TC.

Although that the nickel titanium wire had the lowest surface roughness according to AFM test in this study in both as received wires and after thermo-cycling; it has the highest frictional resistance among wires this may be not related to the surface roughness, rather to the material hardness according to as they found that the more surface hardness the less friction is has (NiTi lowest surface hardness and highest friction coefficient among the wires, while more surface hardness of CuNiTi and lower friction coefficient), this result agrees with and disagree with. The BlueNiTi super elastic archwire showed the lowest friction among wires which agreed with in condition of thermo-cycling with a very highly significant difference when compared with NiTi as shown in table 4.

Regarding the effect of thermo-cycling and distilled water incubation on friction, the results in table 5 and table 6 showed increased amount of friction of all three types of archwires after TC, in comparison with same type of archwire in other conditions, which was a very highly significant difference in both NiTi and CuNiTi wires, also results showed a decrease of friction in NiTi wires after DW with highly significant difference between AR and DW.

The scientific explanations to the increased friction after thermo-cycling is that the surface roughness was increased for all the wires after thermocycling according to AFM results in this study (Table 7 and Table 9), although it was statically non-significant, this result agrees with, whilst, there was non-significant difference among different conditions in case of BlueNiTi super elastic archwire, which might be related to the protective oxide layer.

Clinical relevance

Knowledge about the material of orthodontic archwires is the main step to understand the alignment behavior of an archwire in clinical situations, which in turn help in selection of the proper archwire among the many wires available for each case. Orthodontists put in mind the oral environment, as the wires are subjected to thermal fluctuations, and the surface roughness quality of the wire, as it plays a significant role in the sliding resistance, plaque accumulation and biocompatibility of the archwire; and so it's alignment ability and its stable performance. The present study provides the clarification for that selection; however the clinical interpretation of data requires further in vivo study.

The BlueNiTi super elastic archwire was found to be the least wire affected by aging in both thermo-cycling and incubation in distilled water, with the least change in its frictional behavior. This behavior might be preferred during the alignment phase of the comprehensive orthodontic treatment, as it can maintain consistent sliding quality. This wire showed the lowest sliding resistance among the wires after thermo-cycling. While the CuNiTi archwire showed the lowest sliding resistance among the wires in AR condition.

Aging with DW incubation had statically non-significant difference in BlueNiTi and CuNiTi, except in NiTi subgroup showing a significant difference. While TC shows a very highly significant difference in NiTi and CuNiTi.

Therefore, the BlueNiTi archwires are more favorable in the alignment and leveling phase of orthodontic treatment for two reasons; the first, it has more consistent sliding behavior in all conditions than the other wires; second, it has the least sliding resistance among the wires in condition of thermo-cycling, as thermal aging is more representative to oral conditions than the as received condition, and the distilled water aging has no significant effect on friction. On the contrary, the NiTi archwire showed the highest frictional resistance among wires in both, as received wires and thermal aging conditioned wires, and showed the highest fluctuation in sliding friction among conditions.

Conclusion

- BlueNiti archwire had the lowest friction among wires in thermal aging condition, and had the lowest change in frictional behavior in both aging conditions.

- Niti archwire had the highest friction among wires in both as received wires and thermally aged wires, and had the highest change in frictional behavior in both aging conditions.

- Thermo-cycling increase friction of all wires with significant increase in friction of NiTi and CuNiTi.

- Distilled water incubation had statistically non-significant difference.

- Surface Roughness of all types of arch wires was increased after thermo-cycling, although it had statistically non-significant difference.

Declaration of Conflict of Interest

The authors of this manuscript declare that they have no conflicts of interest, real or perceived, financial or non-financial in this article.

Funding

No funding was provided.

References

- Ogata RH, Nanda RS, Duncanson Jr MG, et al. Frictional resistances in stainless steel bracket-wire combinations with effects of vertical defections. Am J Orthod Dentofacial Orthop 1996;109:535-542.

- Braga LC, Vedovello Filho M, Kuramae M, et al. Friction force on brackets generated by stainless steel wire and superelastic wires with and without IonGuard. Dental Press J Orthod 2011; 16:41-e1.

- Kusy RP, Whitley JQ. Frictional resistances of metal-lined ceramic brackets versus conventional stainless steel brackets and development of 3-D friction maps. Angle Orthod 2001; 71:364-374.

- Gandini P, Orsi L, Bertoncini C, et al. In vitro frictional forces generated by three different ligation methods. Angle Orthod 2008; 78:917-921.

- Burrow SJ. Friction and resistance to sliding in orthodontics: a critical review. Am J Orthod Dentofacial Orthop 2009; 135:442-447.

Author Info

Ali Alsaffar* and Shahbaa A. Mohammed

Department of Orthodontics, College of Dentistry, University of Baghdad, Baghdad, IraqCitation: Assessment of Friction and Surface Roughness of a Novel Orthodontic Wire FlexyBlueTitanium. (An in vitro comparative study), J Res Med Dent Sci, 2021, 9(12): 67-74

Received: 01-Dec-2021 Accepted: 15-Dec-2021 Published: 22-Dec-2021