Research - (2021) Volume 9, Issue 8

Dental Burs in Restorative Dentistry and EndodonticsâPast and Present: A Review

Rutuja Rajnekar*, Nikhil Mankar, Pradnya NikhadeManoj Chandak, Anuja Ikhar, Radhika Gupta and Meghna Dugar

*Correspondence: Rutuja Rajnekar, Department of Conservative Dentistry & Endodontics, Sharad Pawar Dental College & Hospital, Datta Meghe Institute of Medical Science (Deemed University), India, Email:

Abstract

Dental burs are the rotary cutting instrument with cutting heads of various shapes and two or more sharp-edged blades. They are necessary for cutting, grinding and removing hard and soft tissues and are designed for attaching on the rotary dental handpiece for fast and efficient dental work. Certain design factors are influencing the relative cutting efficiency with the functional life of the dental bur. The clinician's bur selection will depend on individual preference, the type of procedure, and the bur effectiveness in the given clinical situation. They can be used in the restorative procedure, for cavity preparation, crown preparation, finishing preparation. In endodontics, for various procedures like access cavity preparation, for canal and separated instruments location. Because of diamond instruments' long service life, they have a tremendous clinical impact with greater cutting efficiency in both the enamel and dentin. In recent years, the latest improvements in materials with techniques have been devised. This review of dental burs in dentistry provides an overview of the basic introduction of burs with their modifications in restorative dentistry and endodontics. The article's overall aim is to provide the reader with a comprehensive knowledge of the tools available to produce optimal integrity in dental restoratives and invasive treatment.

Keywords

Dental burs, Tungsten carbide, Diamond

Introduction

The tooth structure removal and shaping is an essential aspect of restorative dentistry. In early dentistry, this used to be a complicated process because of using hand instrument [1]. The word bur is useful for all the rotary cutting instruments having the bladed cutting heads used for removing tooth structure either by the cutting action or by abrading. Dental burs are responsible for revolutionizing dentistry, being used to cut hard tissues like bone, tooth. In the field of conservative dentistry, there is the availability of a wide range of rotary instruments from the stainless steel burs to the tungsten carbide burs to the diamond abrasives, which are used on a dental drill having an air turbine. These dental burs were manufactured at least 300 years before and are still widely used. Dental burs are available in various shapes and sizes, which are considered for definite applications and which can be rotated up to the speed of 500,000 rpm. These can be of steel followed by a coating of tungsten carbide or entirely made of tungsten carbide. Various bur shapes are developed for numerous usage, for cutting, and drilling abilities. Selection of bur is probably centered on quite a few factors: tradition, the shape of bur, the clinical procedure performed, the substrate which is being cut; its sterilization method and disposal [2]. Moreover, the choice is complicated due to the obtainability of these drills in various sizes & coarseness [3]. Choice of the bur with its use is complicated by the fact stating that the cutting efficiency of bur decreases as the bur wears off and due to debris accumulation [4].

History

• Maya with the other ancient cultures used to use the primitive "bow drills" with few different devices for preparing the round ornamental cavities in the teeth [5].

• 1728 Pierre Fauchard, "Le Chirurgien Dentiste" first detailed description of dental practice represented the use of bow drill to prepare teeth with cutters.

• 19th century- The hand drills having steel bur heads had been used by twirling the long handles with the fingers.

• Before the 1890s, for cutting enamel, silicon carbide discs and stones have been used since the carbon steel burs used to be ineffective for cutting the enamel [6].

• 1891, the S.S.White company gave revelation burs, which were the first machine-made steel burs.

• In 1897, Willman and Schroeder of the University of Berlin, Germany, were credited for manufacturing the first diamond bur.

• In 1942, diamond cutting instruments with 5000 rpm were introduced.

• In 1947, Carbide Burs with 12,000 rpm replaced the steel burs.

Classification

There are various classification systems for burs [7].

Based on its mode for attachment in the handpiece

• The Latch type.

• The friction grip type.

Based on its composition

• Stainless steel bur.

• Tungsten carbide burs or

• Combination of both.

Based on the motion of rotation

• Right Bur - one which will cut, on clockwise revolution.

• Left Bur - one which will cut on anticlockwise revolution.

Based on the length of the bur head

• Long/short or regular.

According to its application

• Cutting burs or those used to finish and polish restorations.

According to the shape of the bur

• Round, pear-shaped, inverted cone, wheel-shaped, tapering fissure, end cutting, straight fissure, etc.

Numbering system

In 1891, for the first time, the SS - White Company introduced the numbering system designed for its first machine-made dental burs. In 1955, the ADA, i.e., American Dental Association, accepted nomenclature with slight alterations, and universally, it is being followed. Since the SS White numbering system for a practical procedure is easy, the size numbers of ADA were also the same for maximum burs except the 245 & 271, designated as 330L & 171, respectively [8].

The system is only limited to stainless steel & tungsten carbide burs. In this earlier numbering system, diamond instruments are not included.

The ISO specification 6360International Standards Organization in 1979, introduced a numbering system meant for the dental burs. For the specification of a particular bur, they gave a 15-digit number. Every three digits of the system signify the specific bur parameter, and this 15-digit bur number gives info regarding the bur in five features [9].

• First 3 digit set: The cutting head material.

• Second 3 digit set: The bur shank form.

• Third 3 digit set: The shape of the cutting head.

• Fourth 3 digit set: Indicates the grit size for diamond instruments, which is only applicable for diamond points.

• Fifth 3 digits set: The bur head diameter.

The advantages of ADA adopted the original numbering system• For a long time since this system is being used, the users and manufacturers are used to it; therefore, it is quite difficult to get adapted to the new system.

• The ISO system is neither simple nor avoids confusion, making this vital for users to still adhere to the original numbering system.

• This system represents information with just two or three digits, giving the reason to be still followed than ISO numbering system. For example, 68 will represent a straight fissure bur having 1 mm as head diameter, while similar bur by the ISO system is represented as 500314107000010.

The drawbacks of the ADA system• The numbering has been completed beginning from number 1 used for the round bur & continued in the ascending direction for the available bur head sizes of the similar shape followed by moving to the next shape. Because all types of head shapes don't have different head sizes, leading to confusion.

• The system has a limitation that it doesn't give room for any new bur in the original numbering system.

Bur design

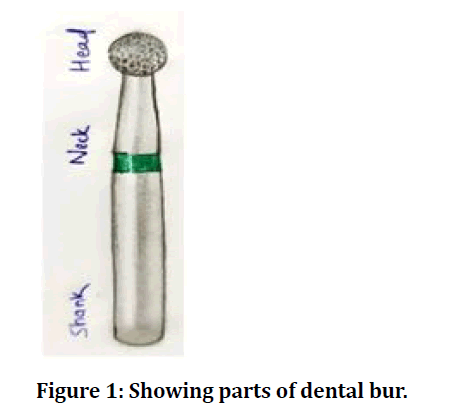

Parts of the dental bur are head, neck, and shank (Figure 1). Bur head has evenly spaced blades having concave areas, i.e., chip or flute spaces in between them. There are 6 to 8 to 10 blades on the cutting bur, whereas on a finishing bur, 12 to 40 blades present [10].

Figure 1: Showing parts of dental bur.

Blade: Bur head projection forming the cutting edge. Having two surfaces:

• Rake face – The bur blade surface on the leading edge.

• Clearance face – The bur blade surface on the trailing edge.

Rake angle: It is the angle amid the rake face & the radial line.

• Positive rake angle: While rake-face used to trail the radial line.

• Negative rake angle: While rake-face is in advance of the radial line.

• Zero rake angle: On coincidence of the rake face with a radial line.

Land: The plane surface directly succeeding bur cutting edge

Clearance angle: Present between clearance face and work, providing a stop for preventing the bur edge from digging tooth structure & for debris clearance the giving significant chip space.

Concentricity: Through the extent of the bur head symmetry.

Run out: Measurement of accurateness when all the blade tips pass through a single point while the bur is rotating, measuring the maximum bur head displacement from its center of rotation.

Modifications of bur designThe three other major changes included [7].

Reduced use of crosscuts: At higher speeds, crosscut bur tends to produce unduly rough surfaces, so now these have been replaced by equivalent non-crosscuts burs to be used at high speeds.

Extended heads on fissure burs: These are introduced for efficient cutting by having a very slight pressure.

Rounding off the sharp tip angles -Introduced by Markley and Sockwell. Rounding off the sharp angles enhances the tooth's strength, and the instrument lasts longer since there is the absence of any sharp corners to chip and wear.

Factors affecting cutting effectiveness and bur efficiency

The instrument ability for removing the maximum amount of tooth tissue by least effort and time will be the cutting efficiency of a rotating dental instrument [11].

Rake angle, clearance angle & the blade angle: The clearance angle decreases friction in the bur cutting edge & the work, preventing digging into the tooth structure. A positive rake angle causes an increase in bur cutting efficiency. In contrast, an increase in the rake angle leads to a reduction in bulk of bur blade (decreases the blade angle) and because of the production of larger chips, there is clogging of the flute space.

Number of blades and their distribution-reduction in the number of the blades will reduce bur cutting efficiency and cause faster debris clearance because of large chip space.

Run out – Average clinically acceptable: 0.023mm. As runout increases, it leads to rising in the bur vibrations with unnecessary tooth structure removal.

Finishing of flutes- Dental bur is manufactured by cutting each flute into the bur blank by a rotating cutter. Those which were cut six times are more efficient whereas those which are cut twice were least efficient.

Heat treatment- causes preservation for cutting edges, further increasing bur shelf life.

Design of the flute ends-

The Revelation design- Together, the flutes join in two junctions adjoining to the diametric cutting edges.

The Star cut design- Together, the flute joins at a mutual point on bur axis. In direct cutting, revelation shows more superiority in cutting efficiency. Whereas in lateral cutting, both have equal efficiency.

Spiral angle-Bur having lower spiral angles are having better efficiency at high speed.

Influence of load –bur has a maximum load/ force over which its cutting efficiency is decreased because of torque. Normally at high speed, it should range between 60-120gm, while for the low rotational speed, 1000 -1500gm.

Speed influence-Within the limits; faster is the speed; more will be the abrasiveness and high efficiency in the tooth cutting instrument [12].

Stainless steel bur

Earlier the burs were made of steel. These are cut from the steel blanks, making them parallel to the long axis of bur, and toughened to VHN 800. Now, these are mainly used for finishing procedures [13].

Advantage: Perform well by cutting human dentin at the low speed i.e.<5000 rpm

Disadvantage: They dull quickly at high speed or during enamel cutting, reducing the effectiveness in cutting further, leading to greater heat and vibration.

Tungsten carbide bur

Are introduced in the year 1947 and has widely substituted steel burs for tooth preparation. Carbide burs are having heads of cemented carbide where microscopic carbide particles, mostly tungsten carbide, are held together in the matrix of cobalt or nickel. They have VHN in the range of 1650-1700.

In utmost burs, there is an attachment of carbide head on the steel neck (and shank) by the process of welding or brazing.

In parts of the bur where superior wear resistance is unnecessary, there is the substitution of steel for the carbide having certain advantages like permitting the manufacturer with more freedom in designing for achieving the characteristics which are looked-for in the instrument, further allowing budget for the cost of materials used for manufacture [14].

Reisbick & Bunshah stated that the tungsten carbide bur should have radial or negative rake angle for providing strength against the fracture due to the carbide brittleness [15].

Advantages: Perform better than that of the steel bur at all speeds, having a greater advantage at high speed. Carbide is considerably harder than that of steel and is less likely to dull during the cutting.

Disadvantages: Carbide is much stiffer and strong than steel, as well as extra brittle.

Diamond burs

Early diamond rotary instruments used to be manufactured by hammering the diamond powder on soft copper or iron blanks surface. In contrast, the modern diamond, which WH Drendrel in 1932, was made by attachment of the diamond particles on the stainless steel either by the sintering or by a galvanic metal bond. Different techniques are used for production of Diamond burs, mainly, by electrode position, microbrazing with sintering, sintering with binder, and sintering under vacuum [16]. The clinical efficiency of diamond abrasives depends on their size, uniformity, spacing, exposure, and the bonding of the diamond particles.

Diamond particle size is mainly categorized for diamond preparation instruments as one of the following.

• Coarse- grit diamond bur (125-150 μ) Green.

• Medium- grit diamond bur (88-125 μ) Blue.

• Fine - grit diamond bur (60-74 μ) Red.

• Very fine - grit diamond bur (38-44 μ) Yellow.

Advantages• Long service life.

• Greater resistance to abrasion.

• Lower heat generation.

• Superior efficiency for cutting both the enamel and dentin.

Abrasives: Finishing and polishing instruments

Diamond finishing burs

These are used for contouring, adjusting, and smoothening restorative materials, e.g., in composites and porcelain. The incorporation of industrial diamond particles manufactures these burs onto the working surfaces. These are extremely efficient in removing rates of materials, leaving a significant rough surface, requiring further finishing and polishing [17].

Carbide finishing burs

Finishing diamonds are used for contouring, adjusting, and smoothening of restorative materials, like composites and porcelain. Unlike fluted carbide finishing burs, for contouring and finishing, these are available in a variety of shapes. Commonly used burs are having a range of 8 to 40 fluted blades, which could be straight /twisted. To contour and smoothen different restorative materials and the tooth structures, the most commonly fluted carbide finishing bur are having 12, 20, or 40 blades [18]. Due to the less abrasive carbide finishing burs, it can be kinder to the gingival soft tissue margins compared to the diamond bur or the bonded abrasive contouring instruments [17]. For primary contouring and gross reduction so as for improving surface and the marginal quality. There should be in sequence use in carbide finishing burs after using finishing diamonds.

Advances in dental burs

Polymer burs

Polymer bur is a unique rotary instrument that is manufactured by using a medical-grade polyether-ketone-ketone [19].

Principle: The polymer bur design is established on the differential hardness of tooth structure. The enamel has a Knoop hardness of 380-400 approximately & for dentin; it is 66-80 [20]. Whereas for carious dentin, Knoop hardness is of 30KHN [21]. To achieve effective caries removal from the enamel, dentin, and matching KHN with the sound tooth, a polymer instrument with 50 KHN was devised.

Advantage

• Polymer bur excavates only carious part in the tooth, minimizing the chance of odontoblasts exposer resulting in a reduction of the pain and/or sensitivity during cavity preparation or postoperative procedure.

• Rotation is at a speed of 500-800 rpm.

• Due to its working principle, they are for single-use, minimizing the chances for cross-infection in dentistry [22].

Disadvantage

• Technique sensitive.

• Expensive.

• The bur damage chances are greater if it comes in contact with the enamel or the sound dentin during or after the procedure.

• Due to thick smear layer formation formed by polymer burs, it affects the bonding agents' penetrating ability. Thereby decreasing the adhesiveness for the restorative materials, e.g., glass ionomer bonding to tooth structure [23] (Figure 2).

Figure 2: Polymer burs.

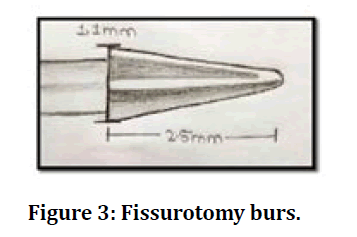

Fissurotomy bur

They are specially designed for pit and fissure lesions for ultraconservative dental treatment.

Fissurotomy bur conservatively widens the fissures providing a large surface for the adhesion of sealant material [24].

The tip of the burs are small and are conservative than 1/4 round bur.

• Fissurotomy Original bur-For conservative pit /fissure excavation of the adult molars.

• Fissurotomy Micro NTF, i.e., Narrow Taper Fissure - For ultraconservative pit/fissure excavation of the adult molars.

• Fissurotomy Micro STF, i.e., Shallow Taper Fissure-For primary teeth, adult premolars and enamelplasty

• Fissurotomy original and NTF have 2.5 mm of head length, whereas for Fissurotomy STF has a head length of 1.5mm (Figure 3).

Figure 3: Fissurotomy burs.

Advantages

• For the early diagnosis and conservative fissure caries preparation, often without e of using anesthesia.

• Minimum heat build-up and vibration.

• Increase in patient comfort.

Disadvantages• Only used with the appropriate restorative materials.

• Expensive.

CVD burs

Chemical vapor deposition, i.e., CVD diamond burs, was introduced in 1996, which were manufactured by the CVD of the diamond film over a molybdenum substrate. The CVD diamond burs connected to an ultrasonic handpiece present unidirectional oscillating movement of maximum displacement, ranging from 50 to 60μm, at oscillating frequencies ranging from 25,000 - 32,000 Hz [25]. Hence, when CVD burs are used with the ultrasound, there is only a slight touch for tooth grinding, whereas conventional rotating techniques promote unnecessary tooth grinding (Figure 4).

Figure 4: CVD burs.

Advantages

• Noise Reduction during the procedure.

• Minimizes damage to gingival soft tissue.

• Long bur durability.

• Upgraded access in the proximal cavity leading to a reduction in chances of damaging the adjacent tooth caused by high inclination angles.

• Minimum patient's risk for metal contamination.

Disadvantages

• Technique sensitive.

• Very costly.

CERA burThe ceraburs (CBs; Komet-Brasseler, Lemgo, Germany) are the all-ceramic round burs which are manufactured by alumina-yttria-stabilized zirconia [26] and these are available in the 4 ISO sizes i.e. 010, 014, 018, and 023(27). These are to be used in a slow-running handpiece at a speed range of 1,000-1,500 rpm [27]. Since Ceraburs have improved mechanical properties, it can be considered as a substitute for tungsten carbide [28].

Advantages

• According to the manufacturer, they have optimal cutting effectiveness, smooth pleasant operation, and the absence of corrosion.

• Ceramic burs have high superior excavating efficiency on soft, carious dentin with minimal cutting of the sound, hard tooth structure. Therefore, these burs should be appropriate for minimally invasive caries excavation [27].

Transmetal bur

The Transmetal Bur is a carbide bur, has an extra-fine crosscut shape which is intended for removing an old amalgam restoration or for cutting through porcelain fused to metal crowns without shattering the porcelain or damaging the bur. The bur has cutting surface length of 5 mm with total length of 19 mm [29].

Since the bur has saw-tooth blade configuration, it provides efficiency while decreasing the undesirable vibration, particularly significant when entering pulpitis or so-called “hot teeth” [30].

LN bur

Teeth with necrosis of the pulp and partial dentin obliteration pose some difficulty during root canal treatment, especially during access.

Partial obliteration of the root canal is often a result of pulp irritation caused by trauma, caries, periodontal disease, abrasion, erosion, attrition, cavity preparations, scaling, or cuspal fractures.

Advantage: Access to a tooth with a partial canal calcification is only possible with a bur extensor connected to an LN bur, and calcification can be bypassed (Figure 5) [31].

Figure 5: LN burs.

CK endoguide bur

These burs have a size of the tip which is less than half as wide as SS White round bur [32].

Minimal invasive endodontics is a concept for preserving healthy coronal, cervical, and radicular tooth structure. Dr. Clark and Khademi introduced EndoGuide burs, also called CK burs. According to Lenchner NH et al., these are ideal for magnification driven endodontics [33].

Advantages

• locate the orifices of the root canal whose access is not in a straight line

• to locate any calcification and obliteration

• To reduce the chances of any procedural errors such as gouging and strip perforation and preserve more paracervical dentin (Figure 6).

Figure 6: Endoguide burs.

Endo Z bur

These are tapered and safe-ended carbide bur [34].

Advantage

• Due to its non-cutting end, they can be safely placed on the pulpal floor without having risk for perforation.

• The lateral bur cutting edges are a flare, flatten, and refinement in the internal axial walls (Figure 7).

Figure 7: Endo Z burs.

Munce discovery burs

They facilitate deep troughing to locate the separated instruments and hidden canals. These have exclusive design features of additional length, facilitating a functional view corridor beyond the handpiece head. The 1mm shaft diameter avoids shaft impingement on deep access cavity walls (Figure 8) [35].

Figure 8: Munce burs.

Comparison with ultrasonic tips, these are having advantages such as

• Inexpensive; Generate no heat

• Create no inconvenient fine dust

• Not prone to spontaneous breakage

LA axxess bur

This bur is designed by Dr. L. Stephen Buchanan. These burs help in optimizing the access preparations [36].

These are basically titanium nitride treated, stainless steel LA Axxess burs (SybronEndo, Orange, CA, USA), having safe ended tips. These burs assures a safer and better significant preflaring in comparison to the conventional drills and files [37].

Multi-purpose bur

These are made of Tungsten Carbide, which are ideal for a various procedures which includes initial access, impacted molars sectioning, cutting of tooth at root level, and separation and amputation of root [38].

They have overall length of 23 mm and the cutting length of 11 mm.

Wear of rotary instruments

Diamond burs have superior cutting efficiency and extent than burs like carbide or stainless steel. Few determinants like surface particle hardness, storage conditions, sterilization and/or disinfection techniques, corrosion, and multiple use have the potential in alteration of diamond burs cutting efficiency [39].

Measurements of the rake angle could be used for assessing the wear of pear-shaped tungsten carbide burs. In the in-vitro studies, significantly reduced lower rake angle was observed in the > 10 cavity preparation group [40].

The diamond burs demonstrates wear by their frequent use in the clinic. The utmost significant relevance of this wearing is the decline in surface roughness of the bur, causing decrease in cutting efficiency. Because of this reason, mainly in prosthetic preparations, diamond burs should be changed after every five preparations [39].

After completing the patients treatment, examine the condition of the bur closely and discard any which are worn or damanged.since using any damaged bur will affect quality of preparation and possibly could cause damage to hard tissues with less cutting efficiency.

Sterilization and disinfection

For controlling cross-transmission of infection, effective techniques for disinfection and sterilization has to be focused on. The most common sterilization method includes soaking the burs in the disinfectors followed by manual cleaning or ultrasonic bath, or autoclave use.

Since autoclave could destroy all the microorganisms including the bacterial spores, therefore found the comparatively best method for decontamination of the dental burs, having few limitations like increase in the fracture susceptibility, reduced cutting efficiency with the life span of burs [41].

For the fast chair side endodontic instrument sterilization, bead sterilizers are commonly used since they could be easily placed in the dental operatory. The burs can be immediately sterilized before, during, and after the surgical procedures, but precleaning is recommended for this instrument. It has been found that using glass bead sterilization is the most effective method for the destruction of fungal contaminants when are compared with the autoclave and remaining groups.

Manufacturers have introduced diamond burs for single patient use due to the dental profession's concerns about infection control [42] (Figure 9). Manufacturers claim that rather than sterilization discarding a single use bur is much more economical.

Figure 9: Single use burs.

Conclusion

Dental burs are vital tool which are necessary for almost every single dental treatment and procedure. Dentists should be educated consumers related to their professional armamentarium. The modern dental equipment allows for efficient removal and shaping of tooth structures and restorative materials. The Hand instruments, rotary-powered cutting burs and abrasive instruments remain the important components of the dental armamentarium. A extensive range of strategic shapes, sizes of instruments are there for use in patient care. Proper knowledge and their use enables optimal execution of dental procedures by presence of insignificant risk to the patient and dental team. Furthermore, new knowledge in this field will aid bur manufacturers in developing more efficient products and helping the dentists for delivering care more swiftly with less trauma to the dental pulp.

References

- Roberson Theodore M, Heymann Herald O, Edward Swift. Strudevant’s arts and science of operative dentistry. 4th Edn. Mosby Publications 330.

- Siegel Sharon C, Fraunhofer Anthony Von. Dental burs-what bur for which application? A survey of dental schools. J Prosthodont 1999; 8:258–26.

- Sharma S, Shankar R, Srinivas K. An epidemiological study on the selection, usage and disposal of dental burs among the dental practioner’s. J Clin Diagnostic Res 2014; 8:250.

- Siegel SC, Von Fraunhofer JA. Cutting efficiency of three diamond bur grit sizes. J Am Dent Assoc 2000; 131:1706-10.

- Mahant R, Agrawal SV, Kapoor S, et al. Milestones of dental history. J Health Res 2017; 4:229.

- Siegel SC, Von Fraunhofer JA. Dental cutting: The historical development of diamond burs. J Am Dent Assoc 1998; 129:740-5.

- Vimal K Sikri. Text book of operative dentistry 4th Edn, CBS publication.

- Council on dental research adopts standards for shapes and dimensions of excavating burs and diamond instruments. J Am Dent Assoc 1963; 67:943.

- Hemamalathi SK, Abarajithan M, Kandaswamy D. A novel simplified numbering system for dental burs. Indian J Dent Res 2008; 19:284.

- Ahmed W, Sein H, Jackson M, et al. Surface engineering of dental tools with diamond for enhanced life and performance. In emerging Nanotechnologies in dentistry, William Andrew Publishing 2018.

- Henry EE, Peyton FA. The relationship between design and cutting efficiency of dental burs. J Dent Res 1954; 33:281-92.

- Marzouk MA, Simonton AL, Gross RD. Operative dentistry, modern theory and practice. 2nd Edn, All India publishers 2001.

- Sturdevent art and science of operative dentistry. 5th Edn.

- Patil C, Jadhav A, Rajanikanth K, et al. Piezosurgery vs bur in impacted mandibular third molar surgery: Evaluation of postoperative sequelae. J Oral Biol Craniofac Res 2019; 9:259-62.

- Reisbick MH, Bunshah RF. Wear Characteristic of burs. J Dent Res 1973; 52:1138.

- Rathi NV, Chandak MG, Mude GA. Comparative evaluation of dentinal caries in restored cavity prepared by galvanic and sintered burs. Contemporary Clin Dent 2018; 9:S23.

- Jefferies SR. Abrasive finishing and polishing in restorative dentistry: A state-of-the-art review. Dent Clin North Am 2007; 51:379-97.

- O’Brien WJ. Dental materials and their selection. In: O’Brien WJ, editor. Chapter 10: Abrasion, polishing, and bleaching. Chicago: Quintessence Books; 2002; 156–64.

- Aswathi KK, Rani SP, Athimuthu A, et al. Comparison of efficacy of caries removal using polymer bur and chemomechanical caries removal agent: A clinical and microbiological assessment-An in vivo study. J Indian Society Pedodont Preventive Dent 2017; 35:6.

- Craig RG, Peyton FA. The microhardness of enamel and dentin. J Dent Res 1958; 37:661-668.

- Fusayama T, Okuse K, Hosoda H. Relationship between hardness, discoloration, and microbial invasion in carious dentin. J Dent Res 1966; 45:1033-1046.

- Haley RW, Quade D, Freeman HE, et al. Study on the efficacy of nosocomial infection control (SENIC Project): Summary of study design. Am J Epidemiol 1980; 111:472-485.

- Andrade R, Parsley CK, Parma R. Polymer burs remove less sound dentin and are as effective as carbide burs in caries removal (UT CAT# 2206). Tex Dent J 2012; 129:672.

- Bagherian A, Akbari M, Rezaeian M, et al. Microleakage assessment of fissure sealant following fissurotomy bur or pumice prophylaxis use before etching. Dent Res J 2013; 10:643.

- Carvalho CA, Fagundes TC, Barata TJ, et al. The use of CVD diamond burs for ultraconservative cavity preparations: A report of two cases. J Esthetic Restorative Dent 2007; 19:19-29.

- Mahdi M, Ismail M, Haidar A, et al. Evaluation of the efficacy of caries removal using papain gel (Brix 3000) and smart preparation bur (in vivo comparative study). J Pharm Sci Res 2019; 11:444-9.

- Dammaschke T, Vesnić A, Schäfer E. In vitro comparison of ceramic burs and conventional tungsten carbide bud burs in dentin caries excavation. Quintessence Int 2008; 39.

- Vusurumarthi V, Ballullaya SV, Pushpa S, et al. Evaluation and comparison of caries excavation efficacy of three different burs: A micro-computed tomographic-assisted study. J Int Soc Prevent Communit Dent 2020; 10:213-219.

- https://www.maillefer.com/product/transmetal-bur/

- https://www.endoruddle.com/tc2pdfs/99/EndoAccess_Oct2007.pdf

- Moraes SH. Bur extensor for root canal access. J Endodont 2001; 27:60-61.

- Anjum SA, Hegde S, Mathew S. Minimally invasive endodontics-A review. J Dent Orofac Res 2019; 15:77-88.

- Makati D, Shah NC, Brave D, et al. Evaluation of remaining dentin thickness and fracture resistance of conventional and conservative access and biomechanical preparation in molars using cone-beam computed tomography: An in vitro study. J Conservative Dent 2018; 21:324.

- Ruddle CJ. Endodontic access preparation the tools for success. Dent Products Report 2007; 1-9.

- http://www.cjmengineering.com/

- https://www.ultimatedental.com/la-axxess.asp

- Verma P, Bains R, Tikku AP, et al. Efficacy of LA Axxess burs, gates glidden drills and protaper sx in obtaining straight line access in mesiobuccal roots of mandibular first molars: A cone-beam computed tomography assessment. Eur J Dent 2016; 10:486.

- https://www.maillefer.com/product/multi-purpose-bur/

- Emir F, Ayyildiz S, Sahin C. What is the changing frequency of diamond burs?. J Adv Prosthodont 2018; 10:93-100.

- Aziz AA, Kasim NA, Ramasindarum C, et al. Wear of rotary instruments: a pilot study. Annals Dent 2011; 18:1-7.

- Sajjanshetty S, Hugar D, Hugar S, et al. Decontamination methods used for dental burs–a comparative study. J Clin Diagnostic Res 2014; 8:ZC39.

- Sharma S, Shankar R, Srinivas K. An epidemiological study on the selection, usage and disposal of dental burs among the dental practioner’s. J Clin Diagnostic Res 2014; 8:250.

Author Info

Rutuja Rajnekar*, Nikhil Mankar, Pradnya NikhadeManoj Chandak, Anuja Ikhar, Radhika Gupta and Meghna Dugar

Department of Conservative Dentistry & Endodontics, Sharad Pawar Dental College & Hospital, Datta Meghe Institute of Medical Science (Deemed University), Sawangi (M), Wardha, Maharshtra, IndiaCitation: Rutuja Rajnekar, Nikhil Mankar, Pradnya NikhadeManoj Chandak, Anuja Ikhar, Radhika Gupta, Meghna Dugar,Dental Burs in Restorative Dentistry and Endodontics–Past and Present: A Review, J Res Med Dent Sci, 2021, 9(8): 163-170

Received: 16-Jul-2021 Accepted: 13-Aug-2021