Research - (2021) Volume 9, Issue 4

Effect of Additional Heat Treatment of Silane-Coated Machinable Ceramics on Bond Strength

Toshio Maseki1*, Chie Tokita1, Seisuke Koshida1, Masahiko Maeno1, Takatoshi Kawai2, Azusa Shirota2 and Masaru Yamase2

*Correspondence: Toshio Maseki, Department of Adhesive Dentistry, The Nippon Dental University, School of Life Dentistry at Tokyo, Tokyo, Japan, Email:

Abstract

The purpose of this study was to investigate the effect of surface treatment with a silane coupling agent combined with heat treatment on bonding to machinable CAD/CAM ceramics. The polished ceramic specimens were treated with a silane coupling agent, or with a silane coupling agent combined with an additional dry heat treatment (100 ºC for 10 min.). The treated specimens were bonded, and tensile bond strengths were measured (n=8) after storage in water at 37 ºC for 1 day and 30 days. In addition, the contact angle values of a flowable resin composite dropped on the three types of ceramic specimen (silanized ceramic specimen, silanized and additional dry treatment specimen, and polished ceramic specimen as control) were measured (n=5). Two-way ANOVA revealed that the effects of heat treatment and storage in water were highly significant (p<0.05). One-way ANOVA and the q-test showed that the differences among the contact angle of three specimens were significant (p<0.05). The application of a silane coupling agent combined with an additional heat treatment increased the bond strength of the machinable CAD/CAM ceramics. However, decrease of bond strength showed that additional heat treatment of the silanized ceramic specimen was not able to completely prevent the degradation of bonding in water storage.

Keywords

Silane coupling agent, Additional heat treatment, Tensile bond strength, CAD/CAM ceramic, Water storage.

Introduction

Dental CAD/CAM systems are currently used for esthetic ceramic inlay and on lay restorations [1,2]. This ceramic restoration is an adhesive restoration, and the adhesion consists of micromechanical attachment to the ceramic surface and chemical bonding with a silane coupling agent [3]. The function of silane coupling is to enhance the bonding of resin cement to the ceramic; this method is well-accepted for clinical restorations [3-5]. The purpose of this study was to investigate the effect of surface treatment by a silane coupling agent combined with heat treatment on the bonding and wettability of the machinable CAD/CAM ceramics.

Materials and Methods

All materials used in this study are listed in Table 1. The CEREC Vitablocs Mark 2 samples were sectioned into specimens of 2.0 mm thickness with a saw microtome and polished with a series of SiC-papers, finishing with 800 grit. The polished ceramic specimens were cleaned with a 35% phosphoric acid etchant gel (Scotchbond Etchant; 3M, St. Paul, MN, USA) and rinsed by water. Then specimens were treated with a silane coupling agent (Ceramic Primer; 3M, St. Paul, MN, USA) in group S or with the silane coupling agent combined with an additional dry heat treatment (100 ºC for 10 min.) in group SH. The treated ceramic specimens were bonded with a dual-cured resin cement system (Opal Luting Composite; 3M, St. Paul, MN, USA) following the manufacturer's bonding procedure (Scotchbond Multi-Purpose Adhesive; 3M, St. Paul, MN, USA). The tensile bond strength (TBS) of the bonded specimens, with 8 specimens in each group, was measured after storage in 37 ºC water for 1 day (24 h) for group S1 and group SH1, and 30 days for group S30 and group SH30, using a universal testing-machine (Autograph AG-1; Shimadzu, Kyoto, Japan) at a cross-head speed of 1.0 mm/ min. The TBS data were statistically analyzed using two-way ANOVA and Student’s t-test in Excel 2016 for Windows (Microsoft, Redmond, WA, USA).

Table 1: Material used.

| Type | Shade | Manufacturer | ||

|---|---|---|---|---|

| CEREC VITA blocks Mark II | I 10 | A3.5c | VITA | |

| Pretreatment agent (Contents) | Saline Coupling Agent | Bonding Agent | Resin cement viscosity | Manufacturer |

| Scotchbond Etchant (35% Phosphic acid) | Creamic powder | Scotchbond Multi-Purpose Adhesive | Opal Luting Composite A+B (High, Warm) | 3 M |

Other specimens were prepared and distributed into 3 groups, silanized ceramic specimens, S; silanized specimens with additional dry heat treatment, H; and polished ceramic specimens, C as control. A drop (0.02 g) of flowable resin composite (Uni-Fil Flow; GC, Tokyo, Japan) was placed on the surface of ceramic specimens and observed by a digital camera with a macro lens (Digital camera D60 and 105 mm Micro Nikkor Macro Lens; Nikon, Tokyo, Japan), and the digital image of each specimen was recorded immediately. The contact angle values of flowable resin composite (n=5) were measured using the software Photoshop CS3 (Adobe, San Jose, CA, USA). The data was statistically analyzed using One-way ANOVA and the q-test in Excel 2016 for Windows.

Results

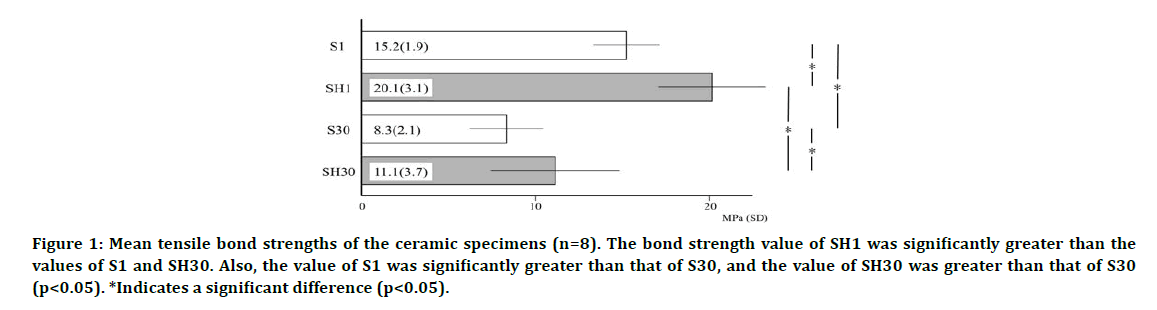

Figure 1 shows data from the tensile bond strength tests. The bond strengths after 1 day of storage were 15.2(1.9) MPa (SD) for group S1, and 20.1(3.1) MPa (SD) for group SH1. The bond strengths after 30 days of storage in water were 8.3(2.1) MPa (SD) for group S30, and 11.1(3.7) MPa (SD) for group SH30.

Figure 1: Mean tensile bond strengths of the ceramic specimens (n=8). The bond strength value of SH1 was significantly greater than the values of S1 and SH30. Also, the value of S1 was significantly greater than that of S30, and the value of SH30 was greater than that of S30 (p<0.05). *Indicates a significant difference (p<0.05).

Two-way ANOVA revealed the significance of two main factors, heat treatment and storage in water (p<0.05), but not their interaction.

The bond strength value of SH1 was significantly greater than the values of S1 and SH30. Also, the value of S1 was significantly greater than that of S30, and the value of SH30 was greater than that of S30 (p<0.05).

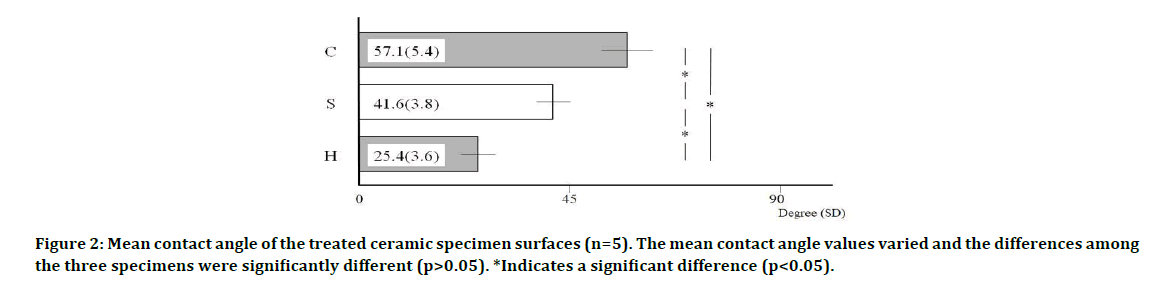

The damping ratios (30 days/1 day, given as percentages) of the bond strengths were 45.4% (group S30 / group S1), and 44.8% (group SH30/group SH1). In Figure 2, the mean contact angle values varied in the order H, 25.4(3.6)<S, 41.6(3.8)<C, 57.1(5.4) degrees (SD), and the differences among the three specimens were significantly different (p >0.05).

Figure 2: Mean contact angle of the treated ceramic specimen surfaces (n=5). The mean contact angle values varied and the differences among the three specimens were significantly different (p>0.05). *Indicates a significant difference (p<0.05).

Discussion

Dental CAD/CAM systems, such as the CEREC system, have been widely used in aesthetic ceramic restorations in recent years for creating inlays, onlays, and veneers and crowns [1,2]. The success of ceramic restoration will depend on the quality and durability of bonding between the ceramic and the resin cement. The silane coupling agent is effective for bonding in ceramic restoration. However, long-term waterstorage conditions cause hydrolysis of the silane coupling agents and decrease the bond strength in vivo and in vitro. Previous studies reported that water absorption at the interface between the ceramics and the luting material influenced the bond strength [6-8].

In this study, the bond strengths varied with the method of surface treatment for the ceramic specimens. The treatment method combining a silane coupling agent with an additional dry heat treatment increased the bond strength. The one-bottle silane coupling agent, i.e. Ceramic Primer, consists of a pre-hydrolyzed silane coupling agent (i.e. MPTS: methacryloxy propyl trimethoxy silane), alcohol solvent and water. Alcohol and water are the solvents required to dissolve the silane agent, and therefore if they remain, the concentration of the silane agent itself will not increase at the ceramic surface. However, alcohol and water appeared to evaporate completely with the additional dry heat treatment, leading to concentration of the silane coupling agent at the surface of the heated specimen.

Roulet et al. reported that evaporation of compounds such as alcohol and acetic acid, which otherwise hydrogen-bond to the silica surface, increases the number of bond sites available for reaction with silane. Also, the heat treatment of silane-coated ceramics drives the silanesilica surface condensation reaction toward completion and promotes covalent silane-silica bond formation [8].

On the other hand, the contact angle test revealed that the wettability of the flowable resin composite was significantly improved by the application of silane coupling agent and additional heat treatment of the silanized surface. Wettability is the result of molecular interactions between the adhesive and the substrate, as well as the cohesion forces of the adhesive, particularly its surface tension [9]. Usually, the wettability of specimen surfaces is evaluated by a contact angle test with water [9,10]. Also, Moreno et al. reported that the application of a hot stream of air (HT) and washing the silanized surface with water at room temperature (WT) resulted in a more hydrophobic layer, increasing the water contact angle [10].

On the contrary, the contact angle was measured using a flowable resin composite resin that has properties closer to an adhesive resin cement than water in this study, and as a result, the contact angle was reduced by the additional heat treatment and high bond strength was obtained. The pre-hydrolyzed silane coupling agent reacts with hydroxyl groups on the surface of silicarich ceramics such as a feldspathic ceramic, and with other silanol oligomers, forming a branched hydrophobic layer [11].

The formation of this cross-linked structure increases the hydrolytic stability of this layer and enhances the penetration of the hydrophobic luting adhesive resin cement into the porous surface of the ceramic and promotes mechanical interlocking [12]. Therefore, it is considered that the application of the silane coupling agent followed by an additional heat treatment resulted in a decrease in the resin contact angle due to the formation of a hydrophobic layer and improvement in the adhesive strength by promoting mechanical interlocking. The reduction in the bond strength of specimens stored in water seemed to have arisen from the well-known weakness of the silane coupling agent, its hydrolytic susceptibility. Therefore, the results from this study show that the effect of dry heat treatment on the maintenance of the bond strength was transient. Komoto et al. [13] revealed that the gain in bond strength after silane treatment followed by additional heating was attenuated by long-term immersion of the sample in water and reported that the effect of water on the adhesive interface cannot be ignored.

A one-day treatment CAD/CAM system like a “CEREC system” needs adjustment just after cementing with a high-speed air turbine and abrasive points. It is important to achieve high bond strength immediately from cementation. In addition, clinically, high bond strength needs to be maintained long-term in the intraoral environment. However, the damping ratio of the bond strength showed that heat treatment was not able to completely prevent the reduction in bond strength caused by storage in water in this study. Silane-silica bonds are hydrophilic, and this property does not change after heat treatment.

Therefore, two other methods can be considered to stabilize silane-silica bonds for a long period of time. The first method is to increase the surface area of the ceramic restorative. Many researchers recommend etching treatment with hydrofluoric acid [7,8,14]. In addition, Maseki et al. [15] used an APF (Acidulated phosphate fluoride) solution, which is safer and easier to handle, instead of hydrofluoric acid to roughen the surface of feldspathic ceramics to obtain high bond strength. The second method is to modify the silane coupling agent. Yoshihara et al. [16] reported that a new silane coupling agent with a long-chain structure was highly effective, and Komoto et al. [13] found that the adhesion reliability was improved by performing an additional treatment irradiating the silane coupling agent with light in the ultraviolet region. In the future, a better prognosis for ceramic restoration may be obtained by using these methods in combination.

The application of the silane coupling agent combined with an additional dry heat treatment was particularly effective for immediate bonding to the ceramics in this study. In future work, the effect of additional treatments on other ceramic restoration methods should be examined.

Conclusion

The application of a silane coupling agent combined with an additional dry heat treatment increased the bond strength of machinable ceramics. However, the damping ratio of the bond strength showed that heat treatment was not able to completely prevent the reduction in bond strength caused by storage in water.

Acknowledgement

The authors declare no conflicts of interest in association with the present study.

References

- Zuellig-Singer R, Bryant RW. Three-year evaluation of computer-machined ceramic inlays influence of agent. Quintessence Int 1998; 29:573-582.

- Mormann WH, Brandestini M, Lutz F, et al. CAD/CAM ceramic inlays and onlays: a case report after 3 years in place. JADA 1990; 120:517-520.

- Hooshmand T, Van Noort R, Keshvad A. Bond durability of the resin-bonded and silane treated ceramic surface. Dent Mater 2002; 18:179-188.

- Hayakawa T, Horie K, Aida M, et al. The influence of surface conditions and silane agents on the bond of resin to dental porcelain. Dent Mater 1992; 8:238-240.

- Kupiec KA, Wuertz KM. Evaluation of porcelain surface treatments and agents for composite-to-porcelain repair. J Prosthet Dent 1996; 76:119-124.

- Maseki T, Nitta T, Shirota A, et al. Bond strength of the various luting systems to the CEREC ceramics. J Dent Res 1995; 74:39.

- Stangel I, Nathanson D, Hsu CS. Shear strength of the composite bond to etched porcelain. J Dent Res 1987; 66:1460-1465.

- Roulet JF, Söderholm KJM. Longmate J. Effects of treatment and storage conditions on ceramic/composite bond strength. J Dent Res 1995; 74: 381-387.

- Sakaguchi R, Ferracane J, Powers J. Craig’s restorative dental materials, St. Louis, Mi, USA, 14th Edn 2019; 274.

- Moreno MBP, Murillo-Gómez F, de Goes MF. Physicochemical and morphological characterization of a glass ceramic treated with different ceramic primers and post-silanization protocols. Dent Mater 2019; 35:1073-1081.

- Matinlinna JP, Vallittu PK. Bonding of resin composites to etchable ceramic surfaces-An insight review of the chemical aspects on surface conditioning. J Oral Rehabil 2007; 34: 622–630.

- Sattabanasuk V, Charnchairerk P, Punsukumtana L, et al. Effects of mechanical and chemical surface treatments on the resin-glass ceramic adhesion properties. J Investig Clin Dent 2016; 8:1–9.

- Komoto M, Maseki T, Nara Y. The effect of additional photochemical treatments on the bonding of silanized CAD/CAM ceramic restorations after water-storage. Odontology 2021; 2.

- Della Bona A, Annussavice KJ, Shen C. Micro tensile strength of composite bonded to hot-pressed ceramics. J Adhes Dent 2000; 2:305-313.

- Maseki T, Komoto M, Koshida S, et al. Effect of APF treatment of CAD/CAM ceramics on bond strength, Online J Dent Oral Health 2021; 4:1-4.

- Yoshihara K, Nagaoka N, Maruo Y, et al. Silane-coupling effect of a silane-containing self-adhesive composite cement. Dent Mater 2020; 36:914–926.

Author Info

Toshio Maseki1*, Chie Tokita1, Seisuke Koshida1, Masahiko Maeno1, Takatoshi Kawai2, Azusa Shirota2 and Masaru Yamase2

1Department of Adhesive Dentistry, The Nippon Dental University, School of Life Dentistry at Tokyo, Tokyo, Japan2Department of General Dentistry, The Nippon Dental University Hospital, Tokyo, Japan

Citation: Toshio Maseki, Chie Tokita, Seisuke Koshida, Masahiko Maeno, Takatoshi Kawai, Azusa Shirota, Masaru Yamase, Effect of Additional Heat Treatment of Silane-Coated Machinable Ceramics on Bond Strength, J Res Med Dent Sci, 2021, 9 (4):263-266.

Received: 01-Apr-2021 Accepted: 16-Apr-2021