Research - (2021) Volume 9, Issue 2

The Influence Using of Two Adhesive Resin Material on the Shear Bond as a new Construction of Artificial Scleral

Souad Hassan Ali* and Akhlas Zeid Abood

*Correspondence: Souad Hassan Ali, Department of Prosthetic Dental Technology, College of Health and Medical Technology, Middle Technical University, Iraq, Email:

Abstract

Background: The device used to simulation of the visible part of the eye is called the ocular prosthesis, that generally used to improve cosmetic, level of function and psychic statue for patient after removed an eye as result to congenital anomaly, external injury and tumor. Objective: The aim of this in vitro study was to valuation the effect using of various resin cements on the shear bond strength between (Heat Clear Acrylic Resin with E-max Heat Press Veneer) for construction of artificial scleral as a new technique. Material and Methods: Twenty rectangle samples, each sample consist of two part (substructure and veneer) of Clear heat cure acrylic resin substructure and IPS E-max Heat Press Veneer ceramic was jointed together by using two types of adhesive (conventional Glass ionomer cement and or Breeze self -adhesive resin cement), (0.3 Milliliter (ml) of adhesive resin cement was applied on the bonding dry surface of each dry part of sample for shear bond strength test. Results: The statistical analysis indicates high significant differences between the (Clear heat cure acrylic resin with ISP E-max ceramic) using Glass inomer cement and in (Clear heat cure acrylic resin with ISP E-max ceramic) using Breeze self-adhesive (P ≤ 0.001). Conclusion: It was concluded that the using of Breeze self -adhesive resin cement showed a better bonding results compared to the conventional Glass ionomer cement for construction of artificial scleral as a new technique.

Keywords

Ocular prosthesis, Acrylic Resin, IPSE-max ceramic, Glass ionomer cement, Breeze self -adhesive

Introduction

Maxillofacial prosthetics is a section of dentistry that deals with congenital and acquired defects of the head and neck. Maxillofacial Prosthetics is a subspecialty of Prosthodontics that involves rehabilitation of patients with defects or disabilities that were present when born or developed due to disease or trauma, this prosthesis used to replace missing areas of bone or tissue and restore oral functions such as swallowing, speech, and chewing and providing acceptable cosmetic and psychosocial state for patient [1-3]. An ocular prosthesis or artificial eye is a type of craniofacial prosthesis that replaces an absent natural eye following birth related deformities and other causes such as accidents and infections, ocular prosthesis is roughly takes the shape of a convex shell and does not provide vision to the patient who suffered from complete blindness and monocular vision and this devise is made of medical grade plastic acrylic, a scleral shell is a very thin hard shell part of ocular prosthesis [4-6].

At first, the ocular prosthesis is made of glass material but this type of material not practical uses due to easy to broken and that became unprofitionle use on Second World War, for this reasons a dental technicians in Royal Navy British they first investigator the utilize of Polymethylmethacrylate material (PMMA) for made ocular prosthetic as substitution of eye glass and appear a more durability properties [7,8].

Clear heat cure acrylic resins are considered as the most commonly substances used in dentistry in the fabrication of scleral part of artificial eyes when mixed with white oil paints to obtain a color similar to the natural eye, generally, white colored acrylic materials are widely used to make the scleral part of the artificial eye. Materials which are used in construction of ocular prostheses must have appropriate properties such as excellent aesthetics, durability, biocompatibility and non-irritating to the eye socket and bilateral stability [9].

Recently have a modern method for construction of an ocular prosthesis by incorporation of a veneer ceramic scleral, by using the IPS E-max heat Press Scleral Veneer (lithium-disilicate or lithium-orthophosphate) this material consist of glass based ceramics, and has accurate mechanical properties like durability, a greater fracture resistance and high flexural strength, high translucency and physical properties (best reluctance to wear and crack prevalence), this properties enable the IPS E-max to use as dental restoration materials [10,11].

Used to joined the IPS E-max veneer with clear heat cure acrylic resin substructure scleral special resin cement material, this material has simplified cementation procedure and not require to addition surface treatment to the substructure surface or veneer surface. The most important properties of dental cement is high durable bond strength, which is required for successful restorative treatment to prevent dislodgement the restoration during function like mastication, another properties such as longevity, low solubility, decreased microleakage, low incidence of marginal staining, and ability to bond to multiple substrates [12-14], this study was designed to assess the effect using of two types of adhesive resin cement on the shear bond strength of artificial scleral constructed from IPS E-max Heat Press Veneer ceramic linked with Heat Clear Acrylic Resin as a new technique.

Materials and Methods

Study sample grouping

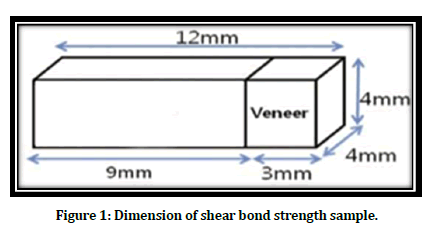

In this study, 20 rectangle shape samples with deamination (12 Millimeters (mm) length X 4mm width X 4mm height) for shear bond strength test that associated to international organization for standardization ISO 9693,1999 [15-18], as shown in figure 1 [18], were divided into two groups according to type of resin adhesive cement use, (10 samples) of clear heat cure acrylic denture resin as substructures with dimension (9mm length X 4mm width X 4mm height) joint with IPS E-max press ceramic as veneer with dimension (3mm length X 4mm width X 4mm height) by using Breeze self -adhesive resin cement, and (10 samples) of clear heat cure acrylic denture resin as substructures with dimension (9mm length X 4mm width X 4mm height) joint with IPS E- max press ceramic as veneer with dimension (3mm length× 4mm width X 4mm height) by using conventional Glass ionomer cement.

Figure 1. Dimension of shear bond strength sample.

Preparation of samples

A silicone mold were used to fabricated a rectangle wax pattren sample for the shear bond strength samples with two part, the first part (substructure) with dimension (9mm length X 4mm width X 4mm height) and the second part (veneer) with dimension (3mm length X 4mm width ×4mm height).

Preparation of substructure clear heat cure acrylic resin

Twenty substructure wax pattern samples that made of clear heat cure acrylic resin (Rodex dental product, Hamburg), using conventional flasking technique for preparation of the substructure mold, Clear heat cured acrylic was mixed according to manufacturer’s instructions (3:1) by volume and adding (1 ml) white oil paint acrylic paint to liquid monomer to get white color9 and mixed it gently then slow addition of powder to liquid. The curing process was carried out by placement the clamped flask in the water bath machine with (74 Degree centigrade (ºC) of heat for about a one hour and thirty minutes (min). Then temperature was increased to the boiling point for thirty minutes according to [19-21]. When curing process is terminated kept the hot flask to cool overnight for deflasking process, removing all the flashes of substructure samples by used an acrylic bur and For standardization the surface of each substructure sample was leveled and flatted by using the grinder/polisher device with using the aluminum oxide abrasive papers (800,1200) grit for (10 seconds) under water then cleaned with distilled water [22], to facilitate handling the sample during the polishing process used a custom holder made from cold cure acrylic resin [23,24]. The final measurements of each substructure part sample (9mm length X 4mm width X 4mm height).

Preparation of veneer IPS E-max ceramic

Twenty veneer rectangle wax pattern samples that made of IPS E-max press ingot (Lithium disilicate ceramic ingots, LTA1, Ivoclar Vivadent), the wax pattern was sprued according to manufacturer's instructions, select two wax pattern samples and weighed for small ingot up to maximum (1 gram (g) of wax, investing is done immediately according to manufacturer's instruction using Ips silicon ring 100g, after completing the setting of the investment material, the investment ring is prepared for preheating by removing the ring gauge, positioning of the investment ring in the preheating furnace at (900c0/1,650 Fahrenheit (f0), after finished preheating process immediately take out the hot ring from the furnace machine then enter the cold IPS E-max press ingot into the hot ring and place the cold Ips Alox plunger at the end of the ring that act as stopper, place the hot ring in the center position of the hot furnace press machine (Ep3010, Ivoclar Vivadent) and select the pressing program that dependence on the IPS E-max press ingot with weight of investment ring according to manufacture in struction. When the pressing procedure is finished removing the investment ring from the furnace press machine and placed it on the cooling grid to cool, according to manufacturer's instructions divesting the investment ring by cutting the sprues with diamond disc,For standardization the veneer flat surface of each sample from one side were polished by abrading with wet grit aluminum oxide (600-1200) the polishing was done under continuous and abundant water cooling at speed 500 rpm [25,26], to facilitate handling the sample during the polishing process used a custom holder made from cold cure acrylic resin [23,24]. The final measurements of each veneer part sample (3mm length X 4mm width X 4mm height).

Cementing the shear bond samples

The two part of shear bond Sample joint to gather by using two types of adhesive, first Breeze self -adhesive resin cement (Breeze Pentron Clinical, Technologies, USA), second Glass ionomer cement (Promedica Dental Material GmbH, German). Table 1 presents the characteristics of the adhesive cement materials used in this study according to manufacture (Breeze Pentron clinical technologies and Promedica dental material).

| Type of adhesive material | Main composition | Delivery system | Working time / setting time | Shades | Manufacturer |

|---|---|---|---|---|---|

| I-Breeze self -adhesive resin cement | -bisphenol-A-diglycidyl methacrylate | Paste/paste dual syringe; direct dispensing through a mixing tip | 1 minute/4 min | Translucent | Breeze Pentron Clinical Technologies,Wallingford, CT, USA |

| -urethane dimethacrylate | |||||

| - triethyleneglycol dimethacrylate | |||||

| - hydroxyethyl methacrylate, | |||||

| - methacryloxyethyl trimellitic acid | |||||

| -silane treated barium glass, | |||||

| - silica (amorphous), Ca-Al-F-silicate | |||||

| II-Glass ionomer cement (glass polyalkenoate cement) | -polyacrylic acid | 35g Powder / 15 ml liquid | 3 min/ 5-7min | Translucent | PROMEDICA Dental Material GmbH, German |

| -fluoro alumino silicate Bases-parabens |

Table 1: Adhesive material used in present study according to manufacture (Breeze Pentron clinical technologies and Promedica dental material).

Breeze self -adhesive resin cement

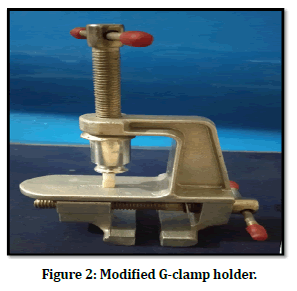

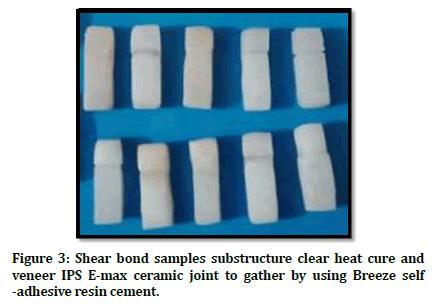

Ten samples of shear bond samples, consist from two part of each sample joint to gather by using Breeze self-adhesive resin cement, they packaged in double barrel syringe with automix tips, at first remove the cap from the syringe and attach the mixing tip to the adhesive syringe then gently pot the cement directly in to the disposable syringe then applied (0.3 ml) on the bonding dry surface of each dry part of shear bond sample to linked the two parts of each sample to gather then all samples subjected to a force of (50g) [27] by using modified G-clamp holder as shown in figure 2.

Figure 2. Modified G-clamp holder.

The setting time is 4 minute according to manufacture constriction, then the excess cement was removed, the final measurements of each sample (12mm ± 0.3 length X 4mm width X 4mm height) were obtained by using the vernier, as shown in figure 3.

Figure 3. Shear bond samples substructure clear heat cure and veneer IPS E-max ceramic joint to gather by using Breeze self-adhesive resin cement.

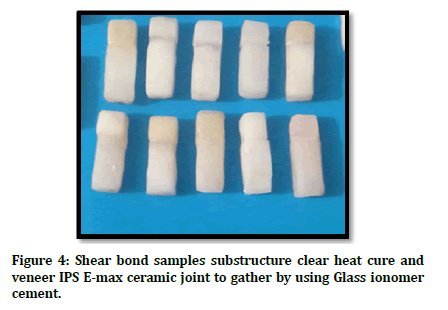

Glass ionomer cement (glass polyalkenoate cement)

Ten samplesof shear bond samples consist from two part of each sample joint to gather by using Glass ionomer cement (glass polyalkenoate cement), is consist of powder (35 g) and liquid (15 ml) packaged in to two bottles ,at first steps mixing one drop of liquid for one level measuring scoop of powder (powder/liquid ratio=3.0:1g/g) according to manufacture constriction ,using a solid cement spatula the mixing time is 30 second and working time 3 minute, then pull the mixing mass by disposable syringe after that applied (0.3 ml) on the bonding dry surface of each part of shear bond sample to linked the two part of each sample to gather, all samples subjected to a force of (50g) 27 by using modified G-clamp holder as shown in figure 2, for (5-7 min setting time) according to manufacture constriction, the excess cement was removed, the final measurements of each sample (12mm ± 0.3 length X 4mm width X 4mm height) were obtained by using the vernier, as shown in figure 4.

Figure 4. Shear bond samples substructure clear heat cure and veneer IPS E-max ceramic joint to gather by using Glass ionomer cement.

Shear bond strength test

Twenty samples shear bond samples measuring by using Instron-1195 testing machine (H3166, England) as shown in figure 5, the each sample was placed in a sample holder and secured to lower jaw tightly and parallel to horizontal plane during the application of the load which was (100 kilogram (kg) Shear bond force was exerted vertically to the bonding interface between the edge of the substructure acrylic and veneering ceramic) with a stainless steel chisel rod at a constant crosshead speed of (0.5 mm/min) and mounted on the universal testing machine until fracture occurred [18,27].

Figure 5. Instron-1195 testing machine, the sample in holder and mounted in a universal testing machine.

The shear bond strength (megapascal (MPa) was calculated by formula:

Shear bond strength (MPa)=Maximum force (newton (N)/bonding area (mm2).

Mode of failure

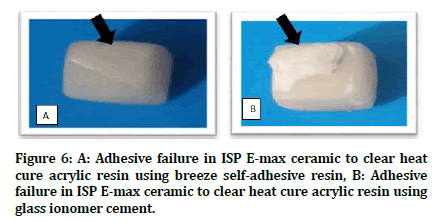

After completion of shear bond testing procedure, all the fractured samples were examined under the stereomicroscope (no. 854230 model BLS200, Italy) and an original magnification of (20X) to determine the mode of bonding failure [17,18,26]. Adhesive failure occurs at interface substructure clear heat cur acrylic resin and veneer IPS E-max ceramic as shown in Figure 6A and Figure 6B).

Figure 6. A: Adhesive failure in ISP E-max ceramic to clear heat cure acrylic resin using breeze self-adhesive resin, B: Adhesive failure in ISP E-max ceramic to clear heat cure acrylic resin using glass ionomer cement.

Statistical methods

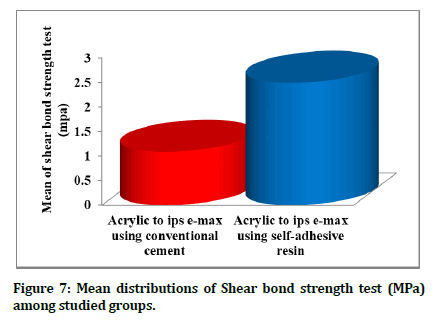

Table 2 and Figure 7 represent the mean(M) and standard deviations (SD) of shear bond strength test for the two groups according to type of adhesive used, the highest mean value of shear bond strength was related in (Clear heat cure acrylic resin linked with IPS E-max) by using Breeze self- adhesive resin (5.359±0.443), while the lowest mean shear bond strength value was related in linked (Clear heat cure acrylic resin with IPS E-max ceramic) using Glass inomer cement (1.612 ± 0.242), and statically analysis represent highly significant difference (Anova test: P=0.00, P<0.01) with tested groups (Clear heat cure acrylic resin with IPS E-max ceramic using Breeze self-adhesive resin and Clear heat cure acrylic resin twith IPS E-max using Glass inomer cement).

| Studied groups (Shear bond strength test) | N | Mean | Std. Deviation | Std. Error | Range | Anova test (P-value) | |

|---|---|---|---|---|---|---|---|

| Mini. | Maxi. | ||||||

| Clear heat cure acrylic resin with IPS E-max ceramic using Glass inomer cement | 10 | 1.612 | 0.242 | 0.076 | 1.29 | 2.09 | P=0.00 Highly significant (P<0.01) |

| Clear heat cure acrylic resin with IPS E-max using Breeze self- adhesive resin | 10 | 5.359 | 0.443 | 0.14 | 4.9 | 6.19 | |

| Total | 30 | ||||||

Table 2: Mean value and Stander Deviation of Shear bond strength test (MPa) among studied groups.

Figure 7. Mean distributions of Shear bond strength test (MPa) among studied groups.

Table 3 shows that the mode failure for Clear heat cure acrylic resin with ISP E-max ceramic the high percentage adhesive failure in (Clear heat cure acrylic resin with ISP E-max ceramic) using Glass inomer cement and in (Clear heat cure acrylic resin with ISP E-max ceramic) using Breeze self-adhesive resin was (100%).

| Test group | Cohesive | Adhesive | Mixed(cohesive and adhesive failure) |

|---|---|---|---|

| Clear heat cure acrylic resin to ISP E-max ceramic using Glass inomer cement | 0 | 100% | 0 |

| Clear heat cure acrylic resin to ISP E-max ceramic using Breeze self-adhesive resin | 0 | 100% | 0 |

Table 3: Types of Failure in Clear heat cure acrylic resin with ISP E-max ceramic using (Glass inomer cement and or Breeze self-adhesive resin).

Discussion

The shear bond strength test was selected in this study because of its simplicity of use, ease of sample preparation and simple test protocol, shear strength is the maximum shear stress which a material is capable of sustaining [18,26]. The present in vitro study assessed the shear strength between IPS E-max ceramic linked with clear heat cure acrylic by using Breeeze selfadhesive resin and or Glass inomer resin cement.

The knowledge of the mechanical properties of adhesive resins is imperative in order to understand and predict their clinical behavior and longevity of this material [12-14]. This study revealed highly significant differences in the shear bond when using conventional Glassionomer cement and or Breeze self-adhesive resin to joint (IPS E-ma ceramic with Clear heat cure acrylic resin part).

The results suggest that shear bond highly depends on the type of material used to link and is affected by the quality of the mechanical properties of the type adhesive material. The self-adhesive resin is provide best merits such as a low solubility, high bonding strength, high compressive strength and high tensile strength, addition to that, its low pH and high hydrophilicity at early stages after mixing, as the hydrophilic and acidic monomers are consumed by the chemical reactions in situ ,the cement becomes more hydrophobic, which is highly desirable in a fully set resin cement to minimize water sorption, hygroscopic expansion, and hydrolytic degradation because of these properties they can be used in status with anxiety for retention of restoration or with weak and esthetic restorations and this allow to considered it as luting cements with multiple applications in modern dentistry and are current popular luting materials with advantages over traditional luting cements [28-30].

Moreover, the characteristic of traditional Glassionomer cement is low tensile strength, a low bonding to the ceramic core or to the tooth, a temperate compressive strength, moisture sensitivity during setting, and predisposition to moisture contamination and desiccation that may happen when exposed to water and saliva pollution during the initial setting period, and this influenced to increase the solubility and decrease the eventual hardness of traditional glass-ionomer cement [29]. All these characteristics lead to poorer mechanical properties than the self-adhesive resin and affect the bonding between the IPS E-max part with clear acrylic part.

The quality of the bond does not depend on nominal values of bond strength but also depend on failure mode analysis of the deboned surfaces which provide valuable information regarding the performance of the materials under forces experienced clinically18. In this study, the table 3 appear the failure mode in groups under stereomicroscope and an original magnification of (20×) indicated that the fracture in (Clear heat cure acrylic resin with ISP E-max ceramic) appear the high percentage was primarily occurred in adhesive failure of (Clear heat cure acrylic resin with ISP E-max) using conventional Glass ionomer cement and in (Clear heat cure acrylic resin with ISP E-max ceramic) using Breeze selfadhesive resin was (100%),this may be related to weak bond between the Clear heat cure acrylic resin and ISP E-max ceramic because there is no bond interference particularly between them which the bond depended on the adhesive material only.

Conclusion

The use of Breeze self-adhesive resin as linked provide the best shear bond strength than the glass ionomer resin cement for the construction of artificial scleral from IPS E-max heat press as a new technique.

References

- Sethi T, Kheur M, Haylock C, et al. Fabrication of a custom ocular prosthesis. Middle East Af J Ophthalmol 2014; 21:271.

- Deepthi V. Maxillofacial prosthetic materials-An update. J Int Med Dent 2016; 3:02-11.

- de Caxias FP, dos Santos DM, Bannwart LC, et al. Classification, history, and future prospects of maxillofacial prosthesis. Int J Dent 2019; 2019.

- Doshi PJ, Aruna B. Prosthetic management of patient with ocular defect. J Indian Prosthodont Society 2005; 5:37.

- Timmermann C, Anderson J. Devices and designs: Medical technologies in historical perspective. Springer.2006

- Raizada K, Rani D. Ocular prosthesis. Contact Lens Anterior Eye 2007; 30:152-162.

- Pine KR, Sloan BH, Jacobs RJ. Clinical ocular prosthetics. Springer Int 2015.

- Gupta RK, Dunderdale GJ, England MW, et al. Oil/water separation techniques: A review of recent progresses and future directions. J Materials Chem 2017; 5:16025-16058.

- Kati FA. Translucency of clear acrylic resin influenced by oil paints. Iraqi Dent J 2018; 40:11-14.

- Costa DA, Aras GC, Chalakkal MA, et al. Ocular prosthesis incorporating IPS e-max press scleral veneer and a literature review on non-integrated ocular prosthesis. Int J Ophthalmol 2017; 10:148.

- Upadhyaya V, Arora A, Singhal J, et al.. Comparative analysis of shear bond strength of lithium disilicate samples cemented using different resin cement systems: An in vitro study. J Indian Prosthodont Society 2019; 19:240.

- Hill E, Lott J. A clinically focused discussion of luting materials. Australian Dent J 2011; 56:67-76.

- Lee Y, Kim JH, Woo JS, et al. Analysis of self-adhesive resin cement microshear bond strength on leucite-reinforced glass-ceramic with/without pure silane primer or universal adhesive surface treatment. BioMed Res Int 2015; 2015.

- Farias DC, Gonçalves LM, Walter R, et al. Bond strengths of various resin cements to different ceramics. Brazilian Oral Res 2019; 33.

- Choi BK, Han JS, Yang JH, et al. Shear bond strength of veneering porcelain to zirconia and metal cores. The J of Advanc Prosthodont 2009; 1:129-135.

- Sreekala L, Narayanan M, Eerali SM, Varghese J. Comparative evaluation of shear bond strengths of veneering porcelain to base metal alloy and zirconia substructures before and after aging–An in vitro study. J Inter Society of Prevent Community Dent 2015; 5:74.

- Hussain AM, AL-Azzawi A. Shear bond strength between lithium disilicate ceramic and different luting cements. J Genet Environ Resour Conserv 2015; 3:12-217.

- Mohammed I, Alwahab ZN. An evaluation of the effect of artificial saliva with different ph on shear bond strength of veneering ceramic to metal and zirconia substructure (in vitro study). World J Pahrma Res 2017; 6:30-44

- https://www.ada.org/en/science-research/dental-standards/dental-products/products-standards-technical-specifications-and-technical-reports

- Al-Taie AZ. Evaluation of olive oil as a separating medium & its effect on some physical & mechanical properties of processed acrylic resin denture base. M Tech Thesis 2006; 27:40-49.

- Aziz H. K. Changes in the transverse strength of heat-cured acrylic denture base by using diodes laser as surface treatment. Tikrit J Dent Sci 2016; 4,102-110.

- Tornavoi DC, Agnelli JA, Lepri CP, et al. Assessment of surface hardness of acrylic resins submitted to accelerated artificial aging. Minerva Stomatol 2012; 61:283-288.

- Akgungor G, Akkayan B, Gaucher H. Influence of ceramic thickness and polymerization mode of a resin luting agent on early bond strength and durability with a lithium disilicate–based ceramic system. J Prosthet Dent 2005; 94:234-241.

- Kim B, Zhang Y, Pines M, et al. Fracture of porcelain-veneered structures in fatigue. J Dent Res 2007; 86:142-146.

- Kim MM, Boahene KD, Byrne PJ. Use of customized polyetheretherketone (PEEK) implants in the reconstruction of complex maxillofacial defects. Archives Facial Plastic Surg 2011; 11:53-57.

- Hasan SF, Abood AZ. Evaluation the effect of hydrofluoric acid and grinding treatment on shear bond strength of ips e. max press with ceramic veneer material (an in vitro study). World J Pharma Res 2017; 6:1-23.

- Roy AK, Mohan D, Sunith M, et al. Comparison of shear bond strengths of conventional resin cement and self-adhesive resin cement bonded to lithium disilicate: An in vitro study. J Contemporary Dent Practice 2017; 18:881-886.

- Al-Ghabban RMJ, Al-Habeeb, Al–Berqdar. Evaluations and comparison of some mechanical properties of the self and hot–cure–acrylic denture base materials under different pressures modality. J Karbala University 2009; 7:1,224-235.

- Paul J. Dental cements-A review to proper selection. Int J Curr Microbiol App Sci 2015; 4:659-69.

- Manso AP, Carvalho RM. Dental cements for luting and bonding restorations: self-adhesive resin cements. Dental Clinics 2017; 61:821-834.

Author Info

Souad Hassan Ali* and Akhlas Zeid Abood

Department of Prosthetic Dental Technology, College of Health and Medical Technology, Middle Technical University, IraqCitation: Souad Hassan Ali, Akhlas Zeid Abood, The Influence Using of Two Adhesive Resin Material on the Shear Bond as a new Construction of Artificial Scleral, J Res Med Dent Sci, 2021, 9 (2): 52-58.

Received: 03-Jan-2021 Accepted: 20-Jan-2021